Color agent for fireworks and crackers and preparation method thereof

A fireworks and color technology, applied in explosives processing equipment, explosives, offensive equipment and other directions, can solve problems such as high risk and environmental pollution of metal powder, and achieve the effects of improving environmental protection, improving color purity, and improving viewing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

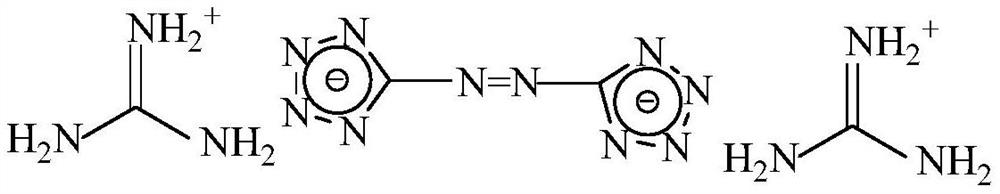

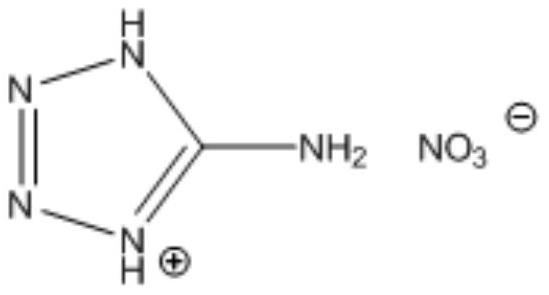

[0028] This embodiment provides a color agent for fireworks and firecrackers, which is composed of the following components: 52 parts of potassium perchlorate, 25 parts of strontium carbonate, 33 parts of azotetrazolium diguanidine, 21 parts of 5-aminotetrazolium nitrate, chlorinated 5 parts of rubber and 5 parts of phenolic resin.

[0029] The present embodiment also provides the preparation method of the above-mentioned color medicament for fireworks and firecrackers, and the steps are as follows:

[0030] First, dry each component to a moisture content of less than 1%, and fully grind it to pass through a 60-mesh sieve;

[0031] Then weigh each component according to the dosage ratio, sieve and mix evenly with a 60-mesh sieve, and sieve and mix three times in order to ensure the uniformity of the medicament;

[0032] The mixed material was granulated while spraying absolute ethanol, and finally dried at 50°C.

Embodiment 2

[0034] This embodiment provides a color agent for fireworks and firecrackers, which is composed of the following components: 46 parts of potassium perchlorate, 20 parts of copper oxide, 29 parts of azotetrazolium diguanidine, 15 parts of 5-aminotetrazolium nitrate, chlorinated 5 parts of rubber and 5 parts of phenolic resin.

[0035] The present embodiment also provides the preparation method of the above-mentioned color medicament for fireworks and firecrackers, and the steps are as follows:

[0036] First, dry each component to a moisture content of less than 1%, and fully grind it to pass through a 60-mesh sieve;

[0037] Then weigh each component according to the dosage ratio, sieve and mix evenly with a 60-mesh sieve, and sieve and mix three times in order to ensure the uniformity of the medicament;

[0038] The mixed material was granulated while spraying absolute ethanol, and finally dried at 50°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com