Dialkyl dithio organic molybdenum as well as preparation method and application thereof

A technology of dialkyldithioorganomolybdenum and dialkyldithio, which is applied in the field of dialkyldithioorganomolybdenum and its preparation, can solve the problems of harsh reaction conditions and poor solubility, and achieve simple separation High efficiency, excellent anti-friction and anti-wear properties, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment provides a method for preparing dialkyldithioorganomolybdenum, comprising the following steps:

[0041] Add 4.53g of molybdenum acetylacetonate MoO to 10.25g of butyl octyl dithiophosphoric acid in absolute ethanol under stirring 2 (acac) 2 (The molar ratio of butyl octyl dithiophosphoric acid to molybdenum acetylacetonate is 2:1), react at room temperature for 8 hours. After the reaction was terminated, the solvent and by-products were spun off to obtain 9.85 g of a brownish-red oily liquid (M202) of butyl-octyl molybdenum dithiophosphate (M202), with a yield of 92.18%, wherein the molybdenum content was 10.86%.

[0042] The above reaction equation:

[0043]

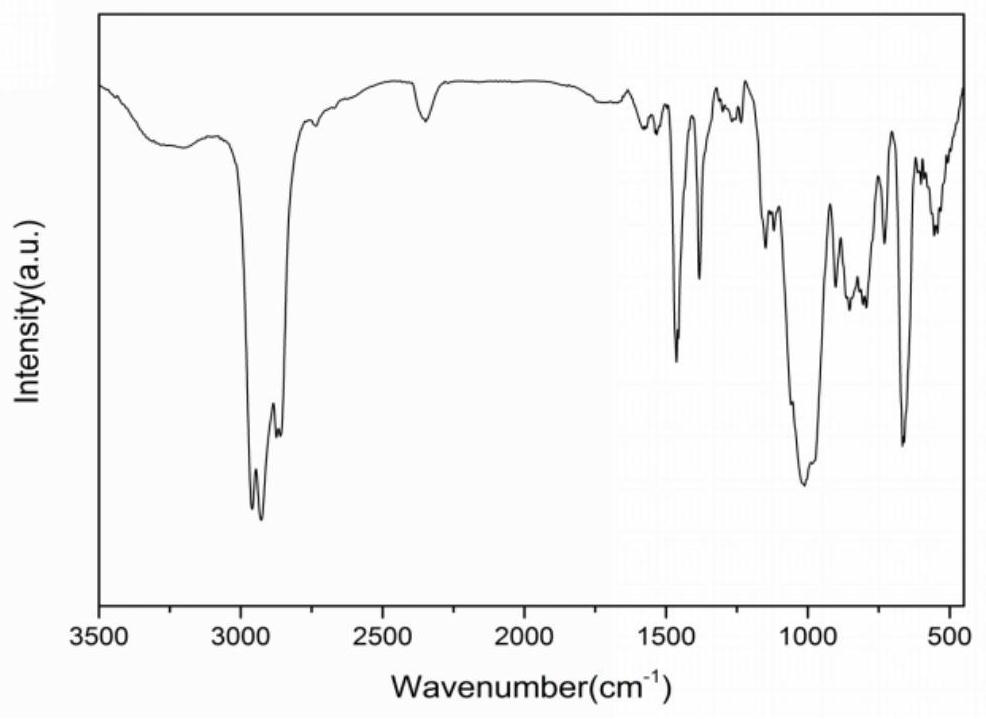

[0044] Implementation effect: see figure 1 , which is an infrared spectrum analysis schematic diagram of the product of Example 1, and the analysis results are as follows: IR (cm -1 ): 2959, 2927, 2874 (-CH 2 -, -CH 3 ); 1585(P=S); 1262(P-O); 1019(P-S,); 905(Mo=O);

Embodiment 2

[0046] This embodiment provides a method for preparing dialkyldithioorganomolybdenum, comprising the following steps:

[0047] Add 4.45g molybdenum acetylacetonate MoO to 10.50g of diisooctyl dithiophosphoric acid in absolute ethanol under stirring 2 (acac) 2 (the molar ratio of diisooctyl dithiophosphoric acid to molybdenum acetylacetonate is 2:1), react at 60°C for 2 hours. After the reaction was terminated, 10.85 g of a brownish-red oily liquid (M204) of molybdenum diisooctyldithiophosphate was obtained after the solvent was removed under reduced pressure, with a yield of 93.86%, wherein the molybdenum content was 9.78%.

[0048] The above reaction equation:

[0049]

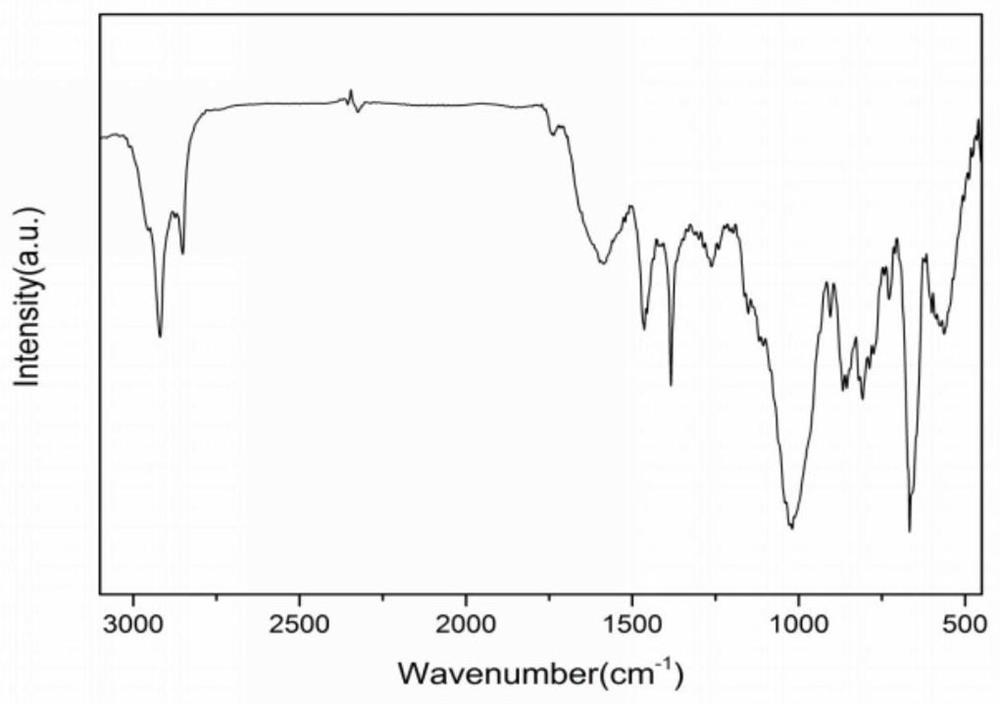

[0050] Implementation effect: see figure 2 , which is an infrared spectrum analysis schematic diagram of the product of Example 2, and the analysis results are as follows: IR (cm -1 ):2919,2951(-CH 2 -, -CH 3 ); 1495(P=S); 1229(P-O); 1011(P-S); 906(Mo=O);

Embodiment 3

[0052] This embodiment provides a method for preparing dialkyldithioorganomolybdenum, comprising the following steps:

[0053] Add 3.26g molybdenum acetylacetonate MoO to 2.60g of di-n-butylamine in dehydrated ethanol solution under stirring 2 (acac) 2 , add 0.76g CS dropwise while stirring at 0°C 2 (di-n-butylamine, molybdenum acetylacetonate and CS 2 The molar ratio is 2:1:2), and reacted at room temperature for 12 hours after the dropwise addition was completed. After the reaction was terminated, the solvent was removed under reduced pressure to obtain 5.16 g of brownish-red oily paste (MoDTC4) of molybdenum dialkyldithiocarbamate (MoDTC4), with a yield of 95.56%, wherein the molybdenum content was 14.35%.

[0054] The above reaction equation:

[0055]

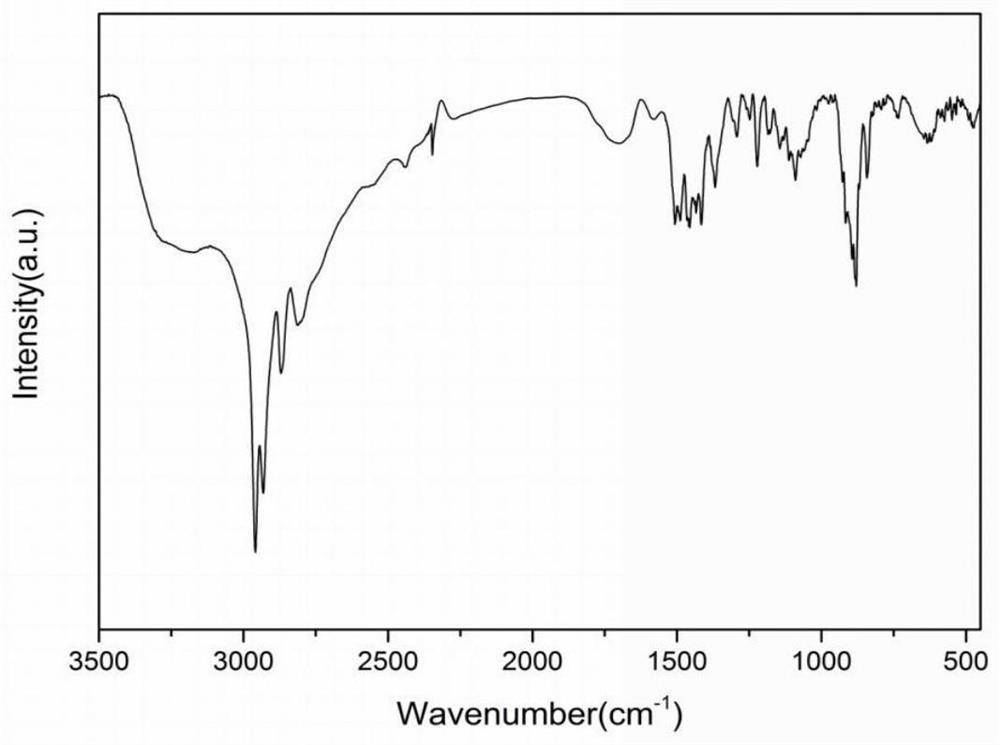

[0056] Implementation effect: see image 3 , which is a schematic diagram of the infrared spectrum analysis of the product of Example 3, and the analysis results are as follows: IR (cm -1 ): 2958, 2931, 2870 (-CH ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com