Synthetic method of polyurethane modified organic silicone oil

A technology of polyurethane modification and silicone oil, which is applied in the direction of improved hand fibers, fiber types, textiles and papermaking, etc., which can solve the problems of easy silicon transfer, weak surface polarity, poor adhesion, etc., and achieve excellent soft hand feeling , improved adsorption performance, and excellent emulsion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

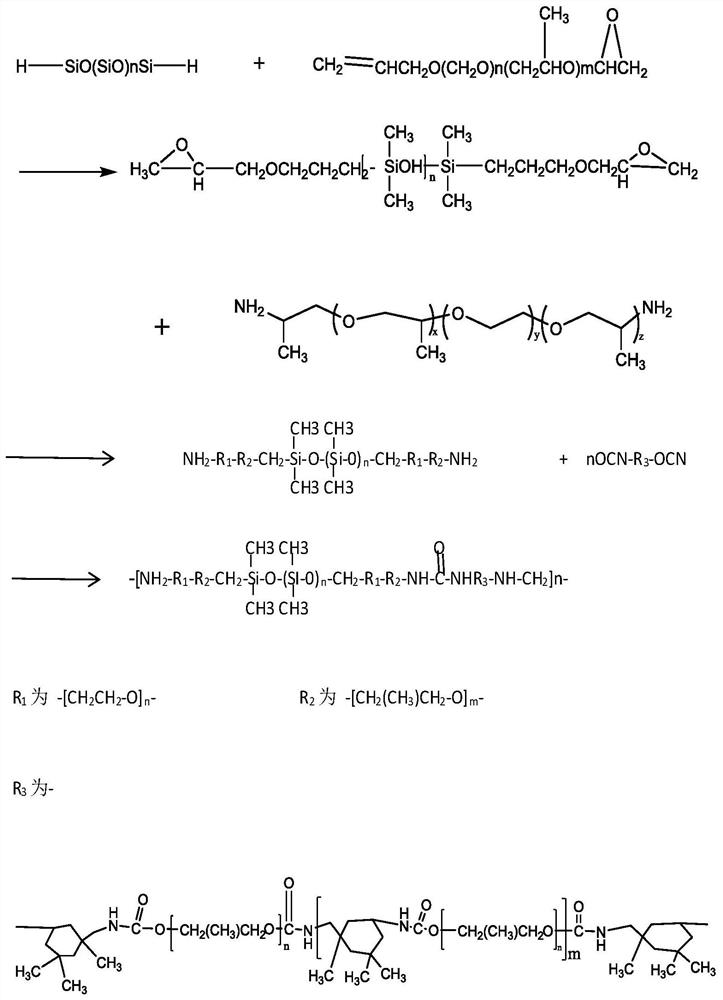

Method used

Image

Examples

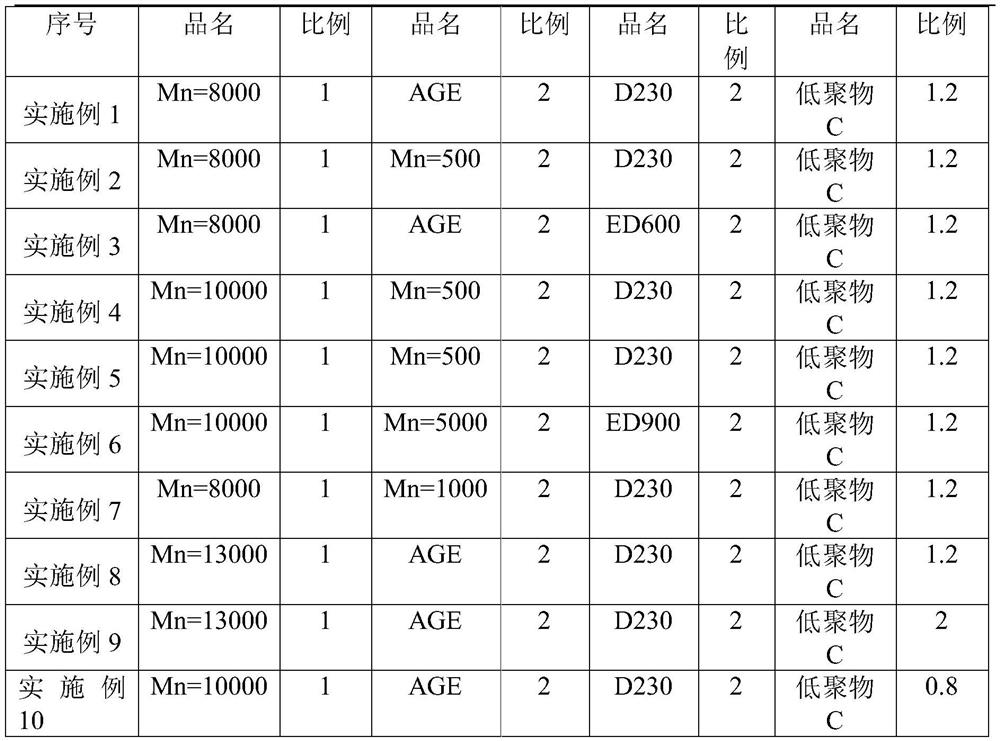

Embodiment 1

[0035] (1), the synthesis of epoxy polyether modified silicone oil intermediate: After soaking the four-necked flask in glacial acetic acid with a mass ratio of 10% (w / w), wash and dry, and 1mol molecular weight is 8000g / mol Terminal hydrogen-containing silicone oil (obtained from Lanxinghuo) and 2mol allyl glycidyl ether (AGE, obtained from Dasao, Japan) were dehydrated and added to the flask in turn, stirred evenly and heated to 70°C, and then added dropwise 16ml of 1% ( g / ml) isopropanol solution of chloroplatinic acid, keep stirring until the temperature rises to 85° C. and keep it warm for 3 hours. After the solution is transparent and no bubbles overflow, cool down and take out to obtain epoxy polyether modified silicone oil A.

[0036] (2) Synthesis of amino polyether modified silicone oil intermediate: add 1 mol epoxy polyether modified silicone oil A, 2 mol double-terminated amino polyether D230 (from Huntsman) to the flask, and heat to 85°C , heat preservation reacti...

Embodiment 2

[0041] (1), the synthesis of epoxy polyether modified silicone oil intermediate: After soaking the four-necked flask in 10% glacial acetic acid, wash and dry, and 1mol molecular weight is 8000g / mol terminal hydrogen-containing silicone oil (obtained from Blue Xinghuo) and 2mol pure PEO allyl epoxy polyether (Mn=500g / mol) (Yangzhou Chenhua New Material Co., Ltd.) were dehydrated and added to the flask successively, then added 30% toluene and stirred evenly and heated to 70 After ℃, add 16ml of 1% (g / ml) isopropanol solution of chloroplatinic acid dropwise, keep stirring until the temperature rises to 85℃ and keep it warm for 6 hours. After the solution is transparent and free of bubbles, cool down and take it out to obtain epoxy polyether Modified silicone oil A.

[0042] (2) Synthesis of amino polyether modified silicone oil intermediate: add 1 mol epoxy polyether modified silicone oil A, 2 mol double-terminated amino polyether D230 (from Huntsman) to the flask, and heat to 85...

Embodiment 3

[0047] (1) Synthesis of epoxy polyether modified silicone oil intermediate: After immersing the four-necked flask in 10% (g / g) glacial acetic acid, wash and dry, 1 mol molecular weight is 8000g / mol terminal hydrogen Silicone oil (obtained from Lanxinghuo) and 2mol allyl glycidyl ether (AGE, obtained from Dasao, Japan) were dehydrated and added to the flask in turn, stirred evenly and heated to 70°C, and then 16ml of 1% (g / ml ) isopropanol solution of chloroplatinic acid, keep stirring until the temperature rises to 85° C. and keep it warm for 3 hours. After the solution is transparent and no bubbles overflow, cool down and take out to obtain epoxy polyether modified silicone oil A.

[0048] (2), synthesis of amino polyether modified silicone oil intermediate: add 1mol epoxy polyether modified silicone oil A, 2mol double-ended amino polyether ED600 (obtained from Huntsman), 40% toluene, Heat to 85°C, keep the temperature for 8 hours, then cool down to room temperature and take ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com