Anti-ultraviolet non-asphalt-based polymer self-adhesive film waterproof coiled material and preparation method thereof

A polymer-based, self-adhesive film technology, applied in the direction of non-polymer organic compound adhesives, adhesives, building insulation materials, etc., can solve the problems of poor high and low temperature resistance, poor UV resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

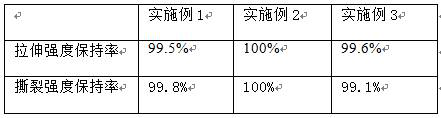

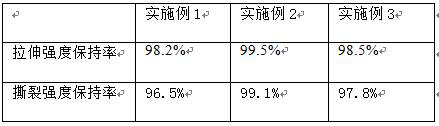

Examples

Embodiment 1

[0034] Example 1 A method for preparing an anti-ultraviolet non-bitumen-based polymer self-adhesive film waterproof membrane

[0035] The preparation method comprises the following steps:

[0036] The preparation method of the anti-ultraviolet non-asphalt-based polymer self-adhesive film waterproofing membrane comprises the following steps:

[0037] Step 1. Preparation of reinforcement layer

[0038] Reinforcing layer: in parts by weight, including the following raw material components: 100 parts of EVA, 8 parts of sodium polyacrylate, 4 parts of wood wax oil, 18 parts of terpene resin, 3 parts of glyceryl monostearate, 1 part of melamine, ultraviolet light 1 part of absorbent, 1 part of calcium stearate, 0.5 part of wood fish stone powder; the ultraviolet absorber: 2-hydroxy-4-n-octyloxybenzophenone and 2-hydroxy-4-methoxydiphenyl A mixture of ketones, the mass ratio is 1:4.

[0039] Weigh the raw materials according to the formula ratio.

[0040] Introduce EVA, sodium po...

Embodiment 2

[0054] Embodiment 2 A kind of preparation method of anti-ultraviolet non-asphalt-based polymer self-adhesive film waterproof coiled material

[0055] The preparation method comprises the following steps:

[0056] The preparation method of the anti-ultraviolet non-asphalt-based polymer self-adhesive film waterproofing membrane comprises the following steps:

[0057] Step 1. Preparation of reinforcement layer

[0058] Reinforcing layer: in parts by weight, including the following raw material components: 110 parts of EVA, 9 parts of sodium polyacrylate, 4.2 parts of wood wax oil, 19 parts of terpene resin, 3.5 parts of glyceryl monostearate, 1.5 parts of melamine, ultraviolet 1.3 parts of absorbent, 1.2 parts of calcium stearate, 0.8 parts of wood fish stone powder; the ultraviolet absorber: 2-hydroxy-4-n-octyloxybenzophenone and 2-hydroxy-4-methoxydiphenyl A mixture of ketones, the mass ratio is 1:4.

[0059] Weigh the raw materials according to the formula ratio.

[0060] ...

Embodiment 3

[0074] Example 3 A method for preparing an anti-ultraviolet non-asphalt-based polymer self-adhesive film waterproof membrane

[0075] The preparation method comprises the following steps:

[0076] The preparation method of the anti-ultraviolet non-asphalt-based polymer self-adhesive film waterproofing membrane comprises the following steps:

[0077] Step 1. Preparation of reinforcement layer

[0078] Reinforcing layer: in parts by weight, including the following raw material components: 120 parts of EVA, 10 parts of sodium polyacrylate, 5 parts of wood wax oil, 20 parts of terpene resin, 4 parts of glyceryl monostearate, 2 parts of melamine, ultraviolet light 1.5 parts of absorbent, 1.5 parts of calcium stearate, and 1 part of wood fish stone powder; A mixture of ketones, the mass ratio is 1:4.

[0079] Weigh the raw materials according to the formula ratio.

[0080] Introduce EVA, sodium polyacrylate, wood wax oil, terpene resin, glyceryl monostearate, melamine, ultraviol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com