Low-density high-thermal-conductivity pouring sealant

A low-density, potting glue technology, applied in the field of potting glue, can solve the problems of high density of potting glue, increased weight of electronic components, and restrictions on the wide application of electronic components, so as to improve flame retardancy, reduce density, The effect of improving compatibility and binding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

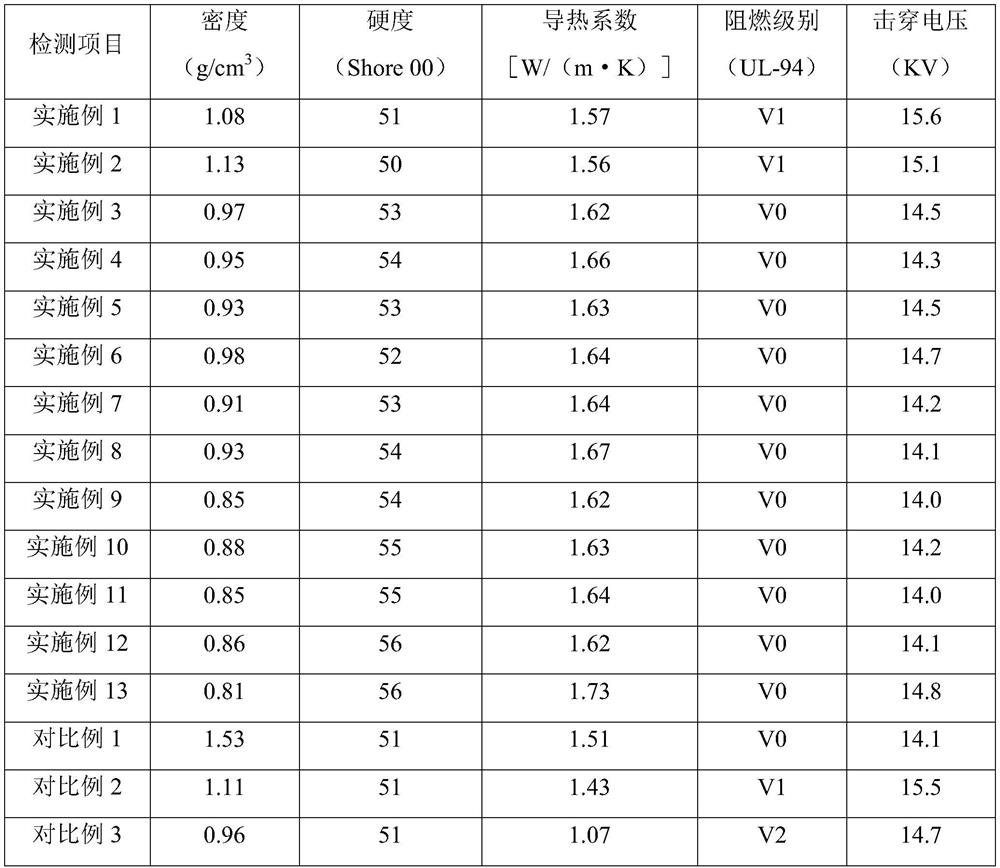

Embodiment 1

[0050] Low density, high thermal conductivity potting compound made from ingredients consisting of the following weights:

[0051] Vinyl silicone oil: 156kg;

[0052] Hydrogen silicone oil: 3 parts;

[0053] Dodecyltrimethoxysilane: 10kg;

[0054] Low density powder: 48kg;

[0055] Thermal powder: 20kg;

[0056] Flame retardant powder: 18kg;

[0057] Platinum catalyst: 0.1kg;

[0058] Simethicone oil: 18kg;

[0059] Among them, the heat-conducting powder is made of aluminum nitride, aluminum hydroxide and aluminum oxide in a mass ratio of 2:1:3, the flame-retardant powder is magnesium hydroxide, and the low-density powder is plastic microspheres.

[0060] The preparation method of the above-mentioned low-density high-thermal-conduction potting glue comprises the following steps:

[0061] S1. Put aluminum nitride, aluminum hydroxide, aluminum oxide and magnesium hydroxide into a ball mill and mix them, then mix them with vinyl silicone oil, hydrogen-containing silicone oil...

Embodiment 2

[0064] Low density, high thermal conductivity potting compound made from ingredients consisting of the following weights:

[0065] Vinyl silicone oil: 185kg;

[0066] Hydrogen silicone oil: 14 parts;

[0067] Vinyltrimethoxysilane: 5kg;

[0068] Low density powder: 34kg;

[0069] Thermally conductive powder: 25kg;

[0070] Flame retardant powder: 21kg;

[0071] Platinum catalyst: 0.2kg;

[0072] Simethicone oil: 29kg;

[0073] Among them, the heat-conducting powder is made of aluminum nitride and aluminum hydroxide mixed at a mass ratio of 2:3, the flame-retardant powder is magnesium hydroxide, and the low-density powder is hollow silica microspheres.

[0074] The preparation method of the above-mentioned low-density high-thermal-conduction potting glue comprises the following steps:

[0075] S1. Put aluminum nitride, aluminum hydroxide and magnesium hydroxide into a ball mill and mix them, and then mix them with vinyl silicone oil, hydrogen-containing silicone oil, vin...

Embodiment 3

[0078] Low density, high thermal conductivity potting compound made from ingredients consisting of the following weights:

[0079] Vinyl silicone oil: 162kg;

[0080] Hydrogen silicone oil: 8 parts;

[0081] Octyltrimethoxysilane: 2kg;

[0082] Low density powder: 43kg;

[0083] Thermal powder: 31kg;

[0084] Flame retardant powder: 25kg;

[0085] Platinum catalyst: 0.3kg;

[0086] Simethicone oil: 24kg;

[0087] Among them, the heat-conducting powder is made of aluminum nitride, aluminum hydroxide and aluminum oxide mixed in a mass ratio of 1:1:3, the flame-retardant powder is magnesium hydroxide, and the low-density powder is hollow glass microspheres.

[0088] The preparation method of the above-mentioned low-density high-thermal-conduction potting glue comprises the following steps:

[0089] S1. Put aluminum nitride, aluminum hydroxide, aluminum oxide and magnesium hydroxide into a ball mill and mix them, then mix them with vinyl silicone oil, hydrogen-containing si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com