Photonic crystal based on laser etching graphene film stack and processing method

A graphene film and photonic crystal technology, applied in laser welding equipment, metal processing equipment, optics, etc., can solve the problems of long time required to modify the structure, low regulation efficiency, narrow regulation range, etc., and achieve good photoelectric tunable characteristics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

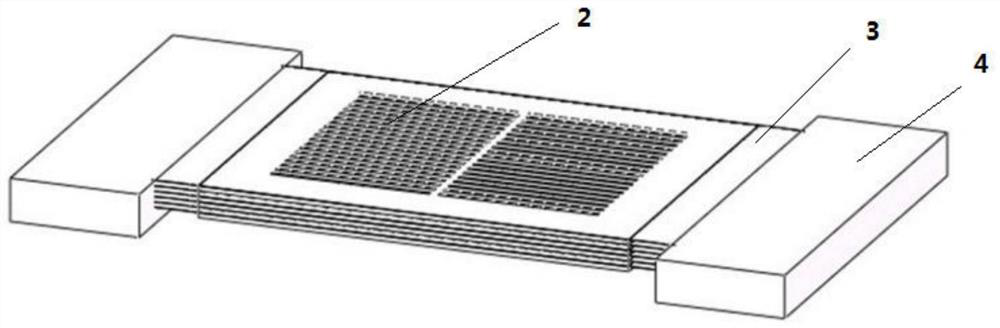

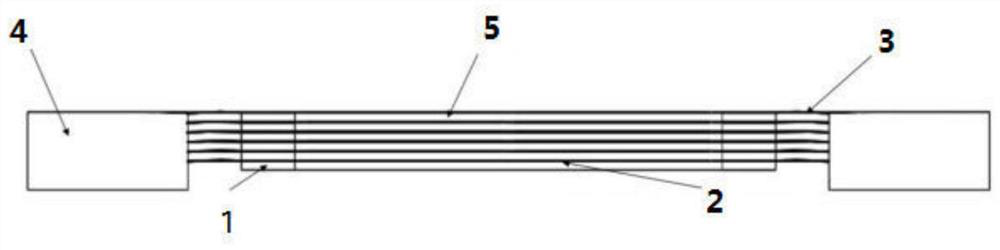

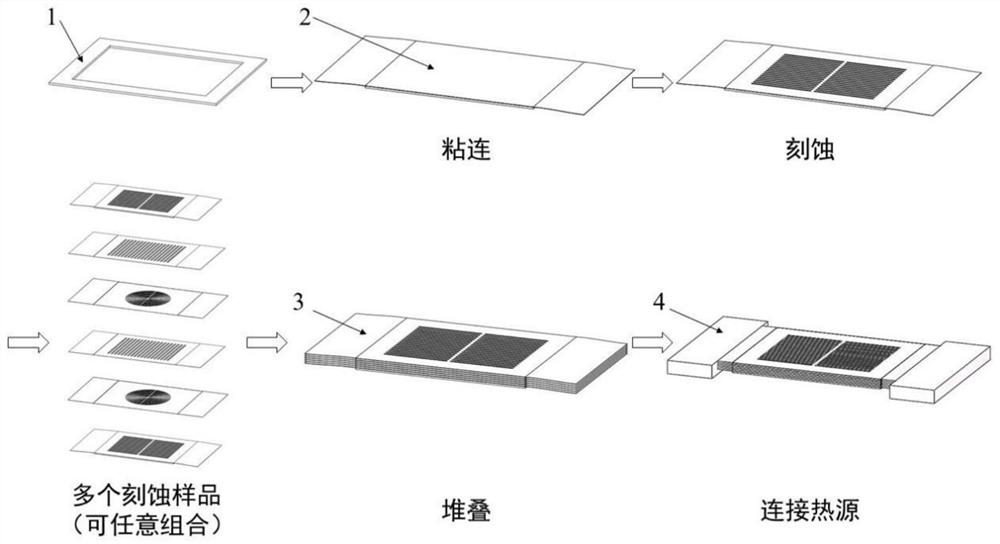

[0028] Such as Figure 1-2 As shown, the present invention provides a photonic crystal stacked based on laser-etched graphene films, including several double-layer crystal structures stacked together, the double-layer crystal structure includes a glass substrate 1 and a graphene film 2, The inside of the glass substrate 1 is hollow, and the periphery is a rectangle; the graphene film 2 is adhered and covered on the glass substrate 1, and its width is consistent with the peripheral width of the glass substrate 1, and its length is greater than the peripheral length of the glass substrate 1 , so that both ends of the glass substrate 1 are left with a graphene film margin 3, so as to connect the heat source. The area corresponding to the hollow part of the annular glass substrate 1 on the graphene film 2 is provided with periodic micros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com