Rechargeable lithium battery

A lithium battery and recharging technology, applied in lithium batteries, non-aqueous electrolyte batteries, battery electrodes, etc., can solve the problems of reduced capacity and low average potential during discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

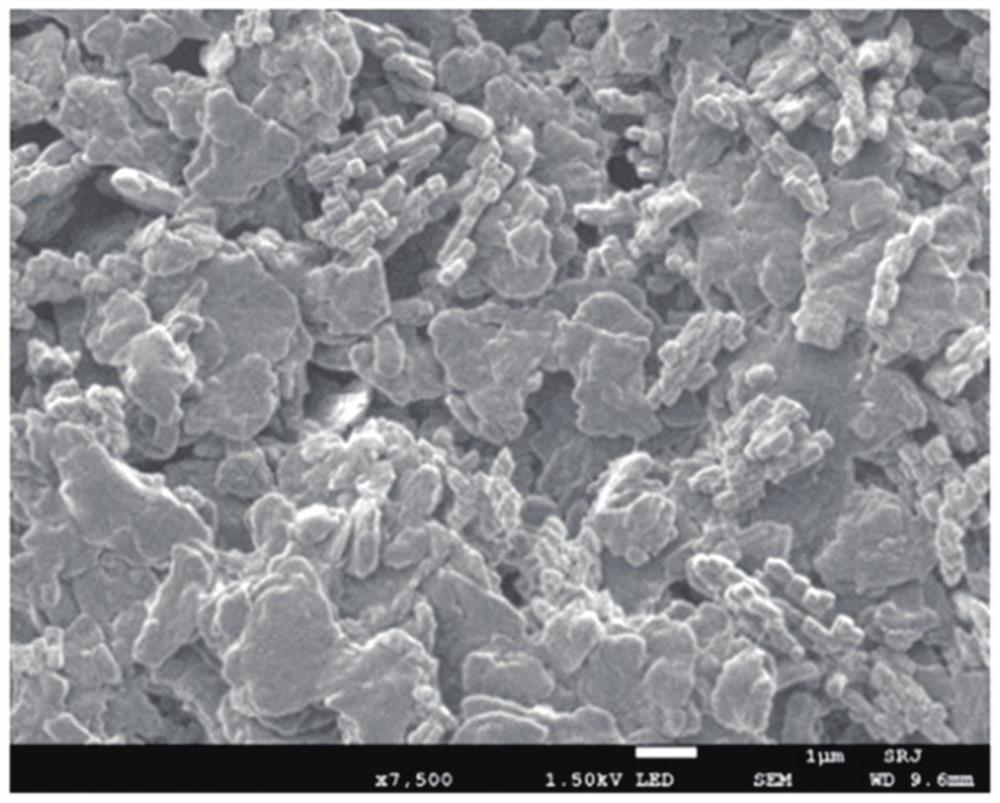

[0109] The positive active material of 95wt%, the polyvinylidene fluoride binding agent of 3wt% and the Ketjen black conductive material of 2wt% are mixed in N-methylpyrrolidone solvent to prepare positive active material slurry, and positive active material is passed through LiCoO 2 / LiFePO 4 It was prepared as the first positive electrode active material / second positive electrode active material mixed at a weight ratio of 9:1. The positive active material slurry was coated on both surfaces of the aluminum current collector, followed by drying and pressing to manufacture a positive electrode having a positive active material layer.

[0110] 98 wt% of graphite, 0.8 wt% of carboxymethyl cellulose, and 1.2 wt% of styrene-butadiene rubber were mixed in pure water to prepare negative electrode active material slurry. The negative active material slurry was coated on both surfaces of the copper current collector, followed by drying and pressing to manufacture a negative electrode...

example 2

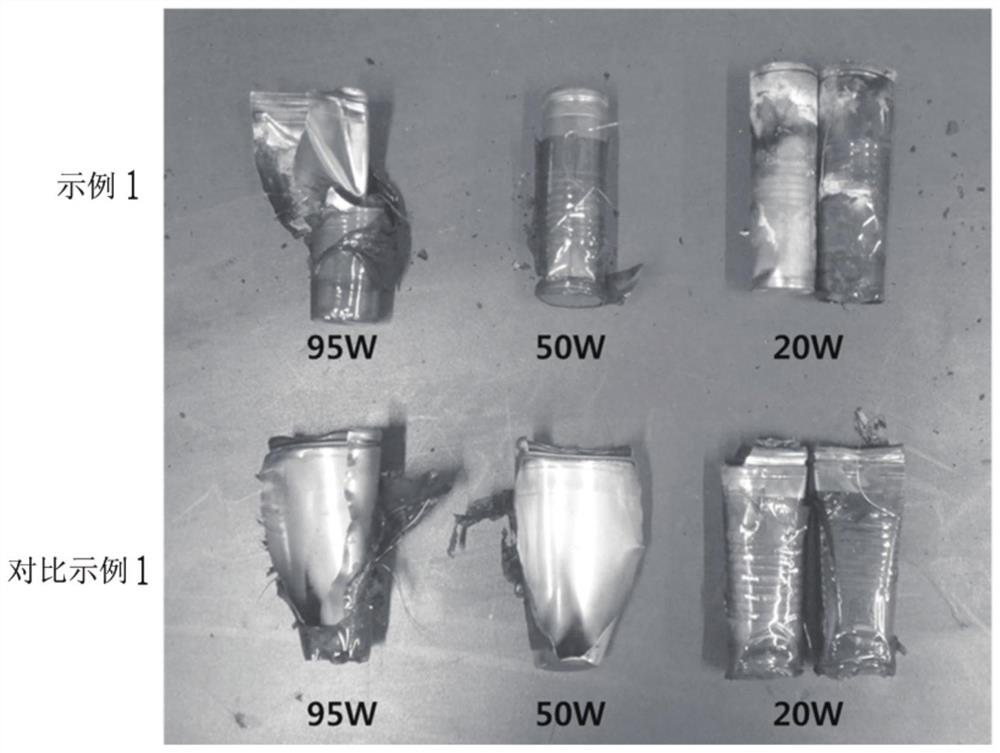

[0130] Evaluation Example 2: Evaluation of Crash Safety

[0131] The rechargeable battery cells of Example 1 and Comparative Example 1 were charged at 0.5C with a cut-off value of 0.05C up to the maximum voltage and aged for 24 hours, and then evaluated as follows.

[0132] ·Place the fully charged unit on a steel plate (thickness ≥ 5cm).

[0133] • Place a round rod (Φ15mm) in the center of the sample, where the round rod should be placed in a vertical direction with respect to the electrodes.

[0134] Cylindrical monoliths are evaluated by placing a round bar in the center like a seesaw shape.

[0135] • A cylinder weighing 9 kg was dropped from a height of 610 mm onto a round bar, the results checked and provided in Table 2.

[0136] The evaluation criteria are as follows.

[0137]

[0138] L1: no effect on appearance

[0139] L2: Visually scratched but no leaks

[0140] L3: Leakage

[0141] L4: Fire

[0142] L5: Explosion

[0143] [Table 2]

[0144] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com