Phytosterol composition for cosmetics, preparation method and application of phytosterol composition

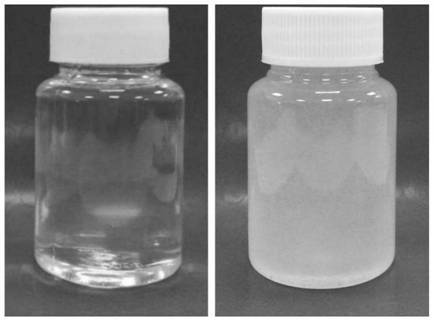

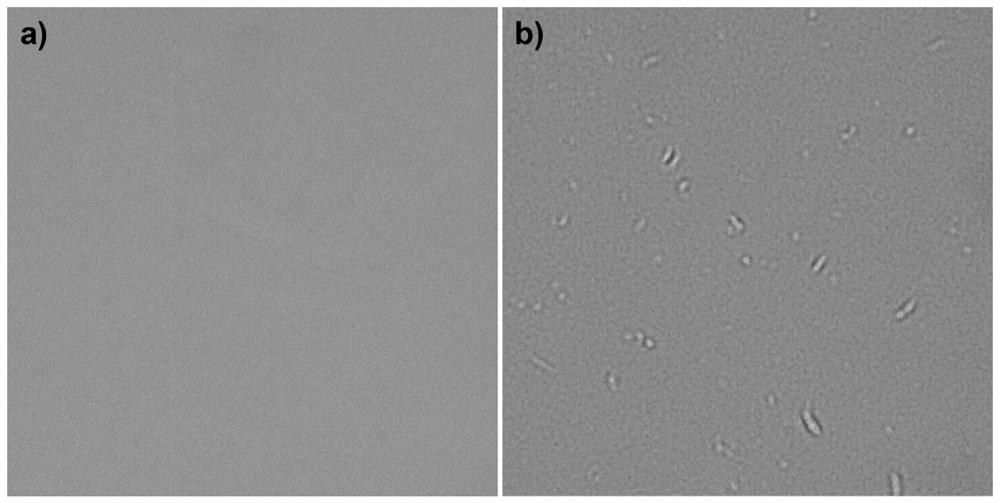

A technology of phytosterols and phytosterol esters, which is applied in the field of phytosterol compositions for cosmetics and its preparation, can solve the problems of common application limitations, poor solubility, incompatible phytosterols and phytosterol esters, etc., and achieve strong operability Sexuality, low melting point, good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

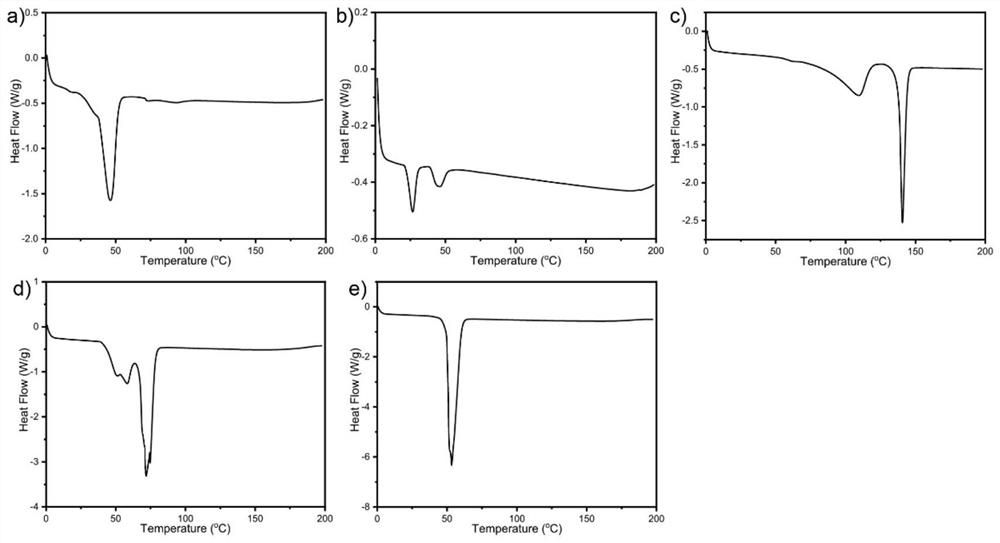

[0032] The preparation of embodiment 1 phytosterol composition of the present invention

[0033] (1) prepare each raw material by following weight portion proportioning;

[0034] Behenyl alcohol 50g, cetyl alcohol 150g, phytosterol 150g, phytosterol ester 150g;

[0035] (2) Mix behenyl alcohol, cetyl alcohol and phytosterol, heat to 80°C, stir at 100 rpm, and react for 40 minutes to obtain solution 1;

[0036] (3) As soon as the temperature of the solution is lowered to 60°C, add the phytosterol ester into the solution 1, stir at a speed of 100 rpm, continue to react for 20 minutes, and cool down to room temperature to obtain the product.

Embodiment 2

[0037] The preparation of embodiment 2 phytosterol composition of the present invention

[0038] (1) prepare each raw material by following weight portion proportioning;

[0039] Behenyl alcohol 20g, cetyl alcohol 100g, phytosterol 100g, phytosterol ester 200g;

[0040] (2) Mix behenyl alcohol, cetyl alcohol and phytosterol, heat to 70°C, stir at 200 rpm, and react for 60 minutes to obtain solution 1;

[0041] (3) As soon as the temperature of the solution is lowered to 60°C, add the phytosterol ester into the solution 1, stir at a speed of 200 rpm, continue the reaction for 10 minutes, and cool down to room temperature to obtain the product.

Embodiment 3

[0042] The preparation of embodiment 3 phytosterol composition of the present invention

[0043] (1) prepare each raw material by following weight portion proportioning;

[0044] Behenyl Alcohol 100g, Cetyl Alcohol 100g, Phytosterol 100g, Phytosterol Esters 100g;

[0045] (2) Mix behenyl alcohol, cetyl alcohol and phytosterol, heat to 100°C, stir at 400 rpm, and react for 5 minutes to obtain solution 1;

[0046] (3) As soon as the temperature of the solution is lowered to 90°C, add the phytosterol ester into the solution 1, stir at a speed of 300 rpm, continue the reaction for 20 minutes, and cool down to room temperature to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com