Carrier for organic compound dehydrogenation catalyst

A technology for dehydrogenation catalysts and organics, which is applied in metal/metal oxide/metal hydroxide catalysts, organic chemistry, physical/chemical process catalysts, etc., and can solve problems such as large floor space, hidden safety hazards, and hidden traffic safety hazards. , to achieve the effect of improving dehydrogenation activity and/or selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

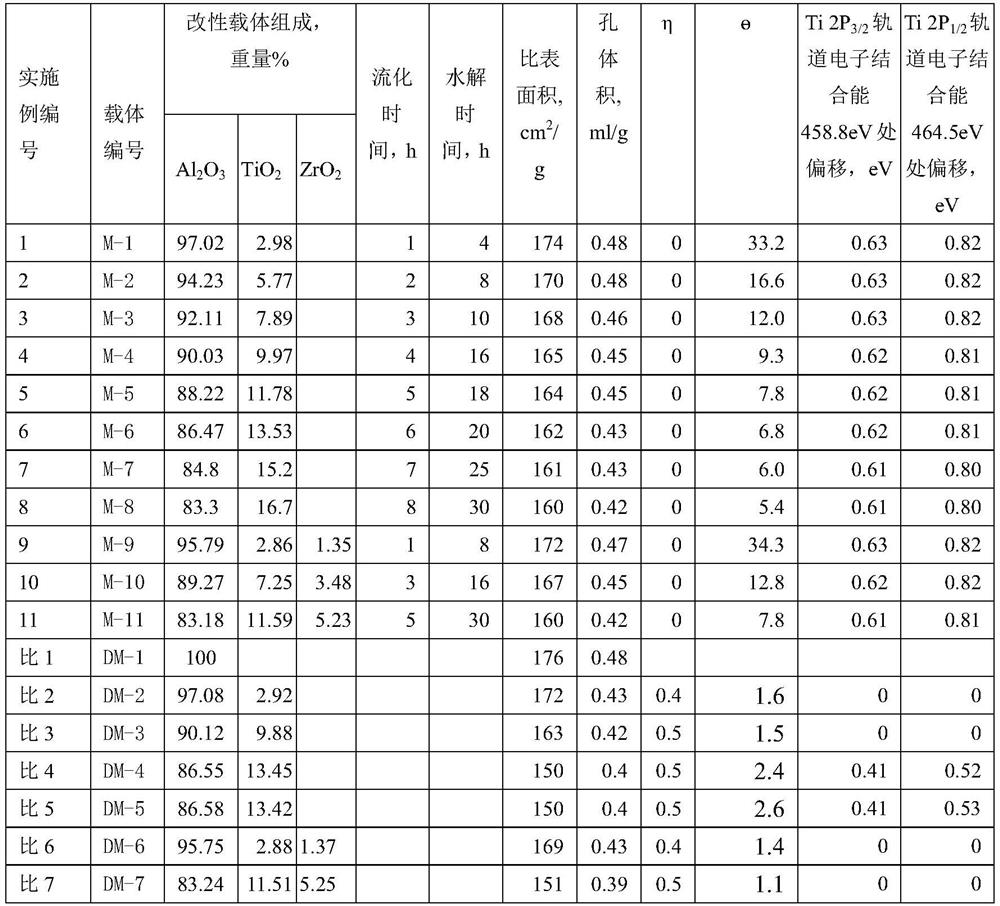

[0059] Calcining SB powder at 500℃ for 4h to obtain γ-Al 2 o 3 , the γ-Al 2 o 3 The specific surface area is 176m 2 / g, the pore volume is 0.48ml / g.

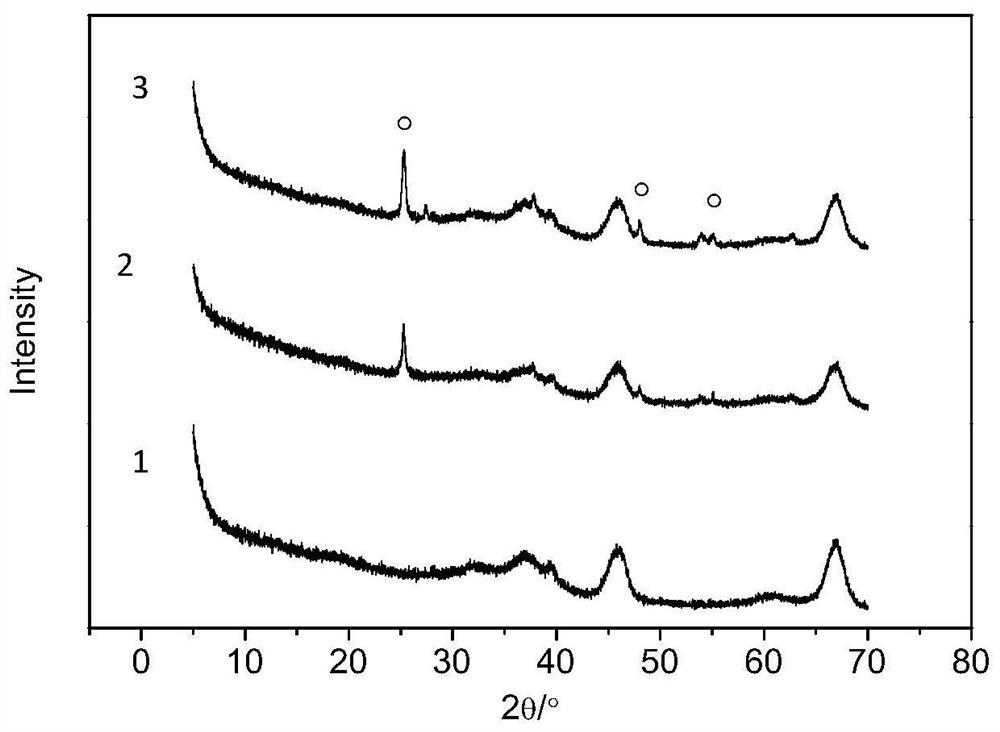

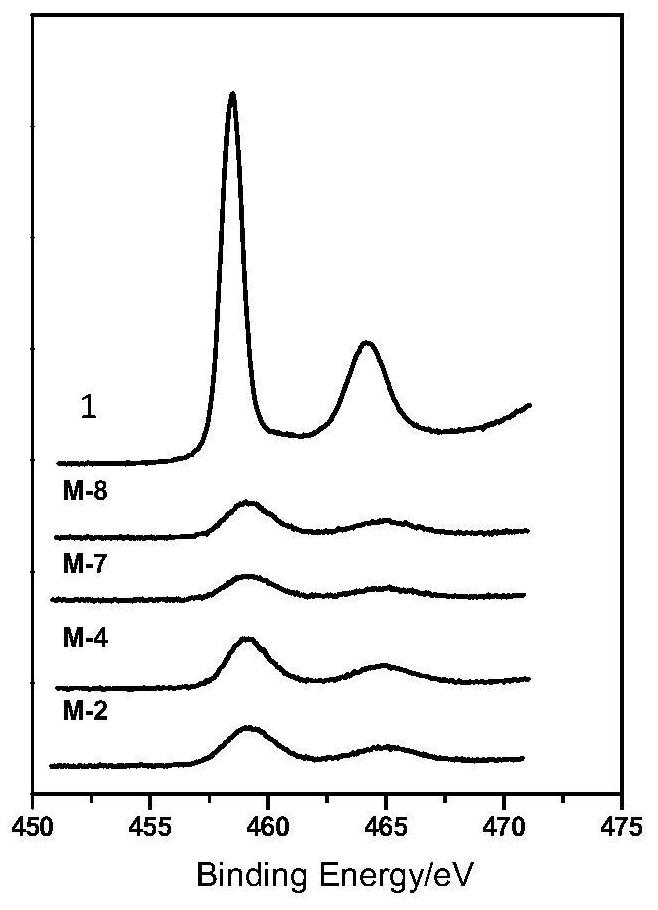

[0060] Take the above γ-Al 2 o 3 500g is placed in the fluidized reactor (the diameter of the reactor is 10cm, and the height is 40cm), titanium tetrachloride is placed in a constant temperature bath at 20°C, and nitrogen (temperature is 25°C) passes through the tetrachloride at a flow rate of 10L / min. Titanium then enters the fluidized reactor from the bottom of the fluidized reactor. After fluidizing for 1 hour, stop passing the nitrogen gas through the titanium tetrachloride bath; The deionized water in the reactor enters the fluidized reactor from the bottom of the reactor, and is fluidized for 4 hours for hydrolysis to obtain a hydrolyzed carrier. The hydrolyzed carrier was calcined in an air atmosphere at 550° C. for 4 hours to obtain a carrier composition, which was named M-1. The properties of the carrier are sh...

Embodiment 2~ Embodiment 8

[0062] The preparation method is the same as carrier preparation example 1, the difference lies in the time for nitrogen to carry titanium tetrachloride into the fluidized bed, and the hydrolysis time for nitrogen to pass through deionized water. The specific values and carrier properties are shown in Table 1.

Embodiment 9~ Embodiment 11

[0064] The preparation method is the same as in Example 1, except that the nitrogen gas first passes through the titanium tetrachloride, and then passes through the zirconium tetrachloride steam generator—the temperature is 300°C. See Table 1 for specific values and carrier properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com