A kind of hydrogenation protection catalyst and preparation method thereof

A hydrogenation protection and catalyst technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problems of high catalyst price and cost, and achieve demetallization High activity, strong impurity capacity, cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Weigh 50 grams of volcanic rock and place it in a beaker, add 500 mL of aluminum nitrate solution with a mass concentration of 32% to the beaker and immerse it for 1 hour to saturate the volcanic rock. The calcined material was impregnated twice by the same method.

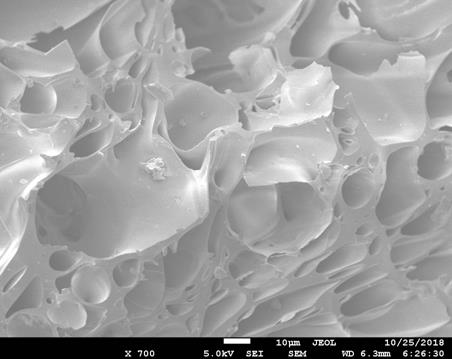

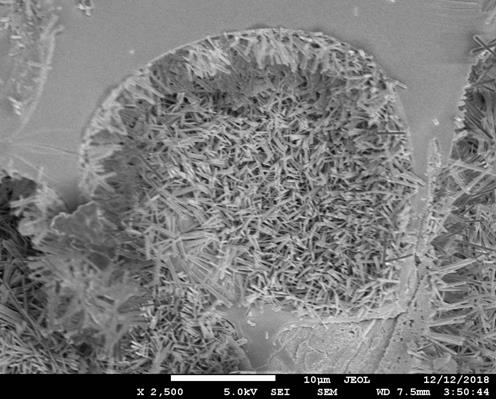

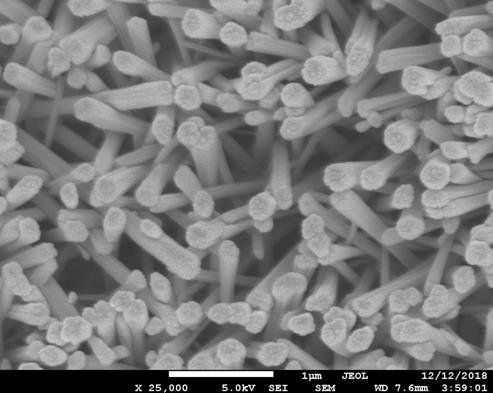

[0035] Weigh 20 grams of volcanic rock after the above-mentioned treatment and place 110 grams of 19% ammonium bicarbonate aqueous solution in mass concentration, transfer the mixture into the autoclave and seal it at 145 ° C for 5.5 hours, then the carrier is dried at 110 ° C for 6 hours , calcined at 800 °C for 4 hours to obtain volcanic rock H1 containing prismatic alumina. The scanning electron microscope photos are as follows figure 1 shown.

[0036] Weigh 20 grams of the above-mentioned volcanic rock containing prismatic alumina, add 50 mL of Mo-Ni-NH 3 Solution (by MoO in final catalyst 35.5 wt%, NiO 1.6 wt%) for 2 hours, filtered off excess solution, dried at 120 °C for 5 hours, and then calcine...

Embodiment 2

[0038] With embodiment 1, just the mass concentration of aluminum nitrate is 36%, the consumption of ammonium bicarbonate solution during heat treatment is 130 grams, and the mass concentration of solution is 22%. The heat treatment temperature was 130°C, and the treatment time was 6 hours. The hydrogenation protection agent Cat-2 was prepared, and the properties of the catalyst are shown in Table 1.

Embodiment 3

[0040] With embodiment 1, only the mass concentration of aluminum nitrate is 40%, the number of times of dipping aluminum salt is 2 times, the consumption of ammonium bicarbonate solution during heat treatment is 150 grams, and the mass concentration of solution is 17%. The heat treatment temperature was 120°C, and the treatment time was 7 hours. The hydrogenation protection agent Cat-3 was prepared, and the properties of the catalyst are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com