Liquid alkali-free accelerator and preparation method thereof

A quick-setting agent and liquid technology, which is applied in the field of building material admixtures, can solve the problems of large fluctuations in product quality, high viscosity of the quick-setting agent, and poor stability, and achieve reduced transportation and use costs, low dosage, and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

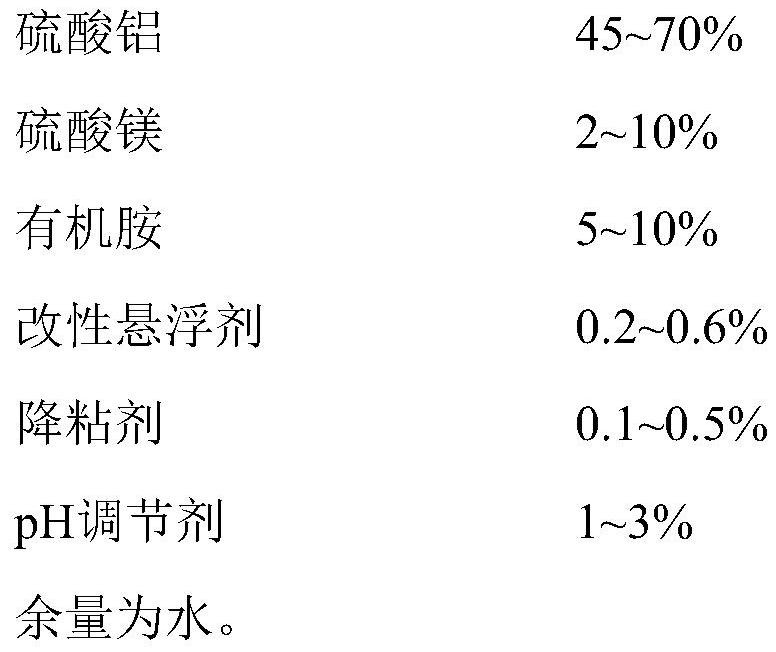

Method used

Image

Examples

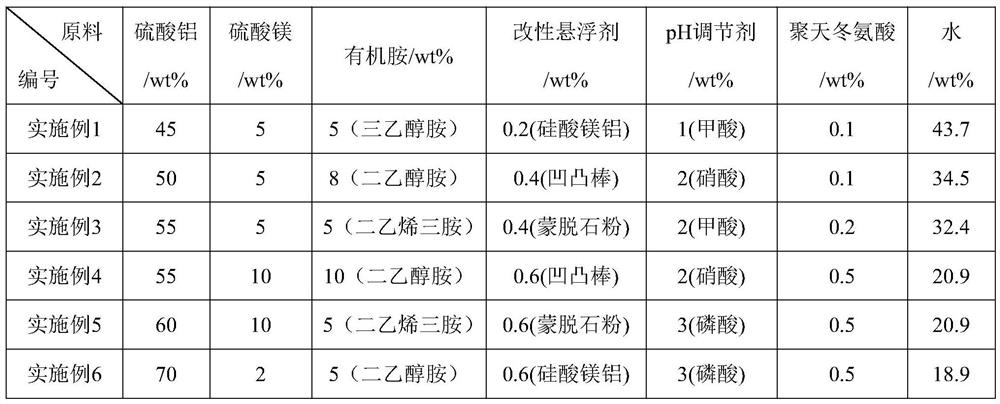

Embodiment 1

[0033] The preparation steps are as follows:

[0034] (1) at first 43.7wt% water and 5wt% triethanolamine are added to the reaction kettle at a constant temperature of 50°C and stirred;

[0035] (2) adding 0.2wt% modified suspending agent (magnesium aluminum silicate), stirring continuously for 2h to complete dispersion;

[0036] (3) adding 45wt% aluminum sulfate and 5wt% magnesium sulfate successively, and stirring continuously for 3h to complete dispersion;

[0037] (4) adding 0.1wt% polyaspartic acid and stirring for 30min;

[0038] (5) finally adding 1wt% formic acid and stirring for 12min to obtain the low viscosity high performance liquid alkali-free quick-setting agent.

Embodiment 2

[0040] The preparation steps are as follows:

[0041] (1) at first 34.5wt% water and 8wt% diethanolamine are added into the reactor at constant temperature of 50°C and stirred;

[0042] (2) Add 0.4wt% modified suspending agent (attapulgite), continue stirring for 1h to complete dispersion;

[0043] (3) adding 50wt% aluminum sulfate and 5wt% magnesium sulfate successively, stirring continuously for 3h to complete dispersion;

[0044] (4) adding 0.1wt% polyaspartic acid and stirring for 30min;

[0045] (5) finally adding 2wt% nitric acid and stirring for 12min to obtain the low-viscosity high-performance liquid alkali-free quick-setting agent.

Embodiment 3

[0047] The preparation steps are as follows:

[0048] (1) 32.4wt% of water and 5wt% of diethylenetriamine are added to the reaction kettle at a constant temperature of 55°C and stirred;

[0049] (2) add 0.4wt% modified suspending agent (montmorillonite powder), continue stirring for 3h;

[0050] (3) adding 55wt% aluminum sulfate and 5wt% magnesium sulfate successively, stirring continuously for 3h to complete dispersion;

[0051] (4) add 0.2wt% polyaspartic acid, stir 30min;

[0052] (5) finally adding 2wt% formic acid and stirring for 18min to obtain a liquid alkali-free accelerator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com