Method for rapidly treating organic waste

An organic waste and rapid technology, applied in the direction of organic fertilizer, inorganic fertilizer, fertilizer mixture, etc., can solve the problems of low silicon activity, aluminum pollution, high pH value, etc., and achieve the goal of increasing soil fertility, increasing root formation, and improving utilization efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

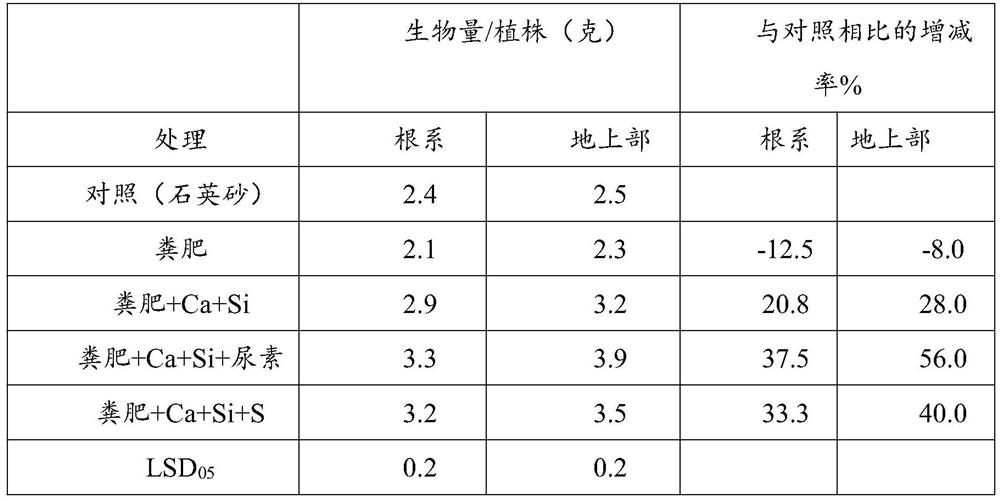

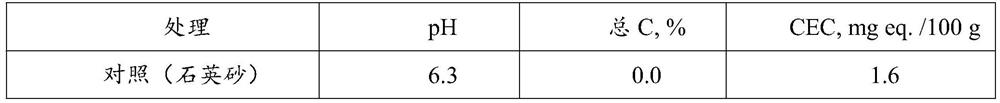

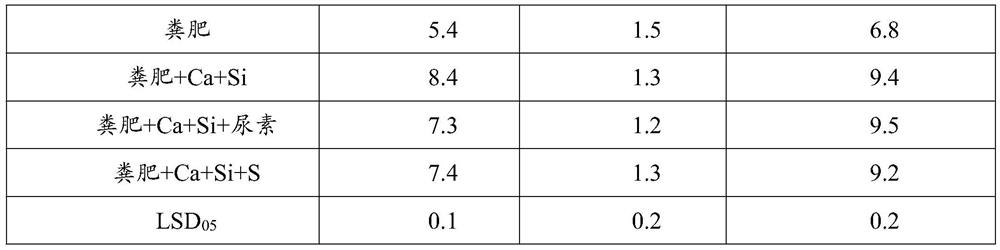

Examples

Embodiment 1

[0046] A method for rapidly processing organic waste, comprising the steps of:

[0047] The first step: control the moisture content of organic waste at 30-80%;

[0048] Step 2: Weigh the water-containing organic waste and CaO according to the weight ratio of water-containing organic waste: CaO in a ratio of 1:1 to 100:1;

[0049] The third step: mixing the aqueous organic waste with CaO to obtain a mixture of aqueous organic waste and CaO;

[0050] Step 4: Weigh the silicon-rich solution at a ratio of 1:1 to 10,000:1 by weight of aqueous organic waste: silicon-rich solution:

[0051] Step 5: Continue mixing the aqueous organic waste and CaO mixture with the silicon-rich solution.

[0052] The particle size of the CaO is less than 1 mm, the concentration of monosilicic acid in the silicon-rich solution is 0.1-20%, and the monosilicic acid is H 2 SiO 4 , the treatment time between aqueous organic waste and CaO mixture and silicon-rich solution ranges from 1 minute to 2 mont...

Embodiment 2

[0070] A method for rapidly processing organic waste, comprising the steps of:

[0071] The first step: control the moisture content of organic waste at 30-80%;

[0072] Step 2: Weigh the water-containing organic waste and CaO according to the weight ratio of water-containing organic waste: CaO in a ratio of 1:1 to 100:1;

[0073] The third step: mixing the aqueous organic waste with CaO to obtain a mixture of aqueous organic waste and CaO;

[0074] Step 4: Weigh the silicon-rich solution at a ratio of 1:1 to 10,000:1 by weight of aqueous organic waste: silicon-rich solution:

[0075] Step 5: Continue mixing the aqueous organic waste and CaO mixture with the silicon-rich solution.

[0076] The particle size of the CaO is less than 1 mm, the concentration of monosilicic acid in the silicon-rich solution is 0.1-20%, and the monosilicic acid is H 2 SiO 4 , the treatment time between aqueous organic waste and CaO mixture and silicon-rich solution ranges from 1 minute to 2 mont...

Embodiment 3

[0090] A method for rapidly processing organic waste, comprising the steps of:

[0091] The first step: control the moisture content of organic waste at 30-80%;

[0092] Step 2: Weigh the water-containing organic waste and CaO according to the weight ratio of water-containing organic waste: CaO in a ratio of 1:1 to 100:1;

[0093] The third step: mixing the aqueous organic waste with CaO to obtain a mixture of aqueous organic waste and CaO;

[0094] Step 4: Weigh the silicon-rich solution at a ratio of 1:1 to 10,000:1 by weight of aqueous organic waste: silicon-rich solution:

[0095] Step 5: Continue mixing the aqueous organic waste and CaO mixture with the silicon-rich solution.

[0096] The particle size of the CaO is less than 1 mm, the concentration of monosilicic acid in the silicon-rich solution is 0.1-20%, and the monosilicic acid is H 2 SiO 4 , the treatment time between aqueous organic waste and CaO mixture and silicon-rich solution ranges from 1 minute to 2 mont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com