Saturated polyester type low-shrinkage additive and application thereof

A low-shrinkage additive and polyester-based technology, which is applied in the field of polymer compound synthesis, can solve problems such as uneven coloring, poor coloring performance, and failure to meet performance requirements, and meet high-quality requirements, good coloring performance, and synthetic process conditions. mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

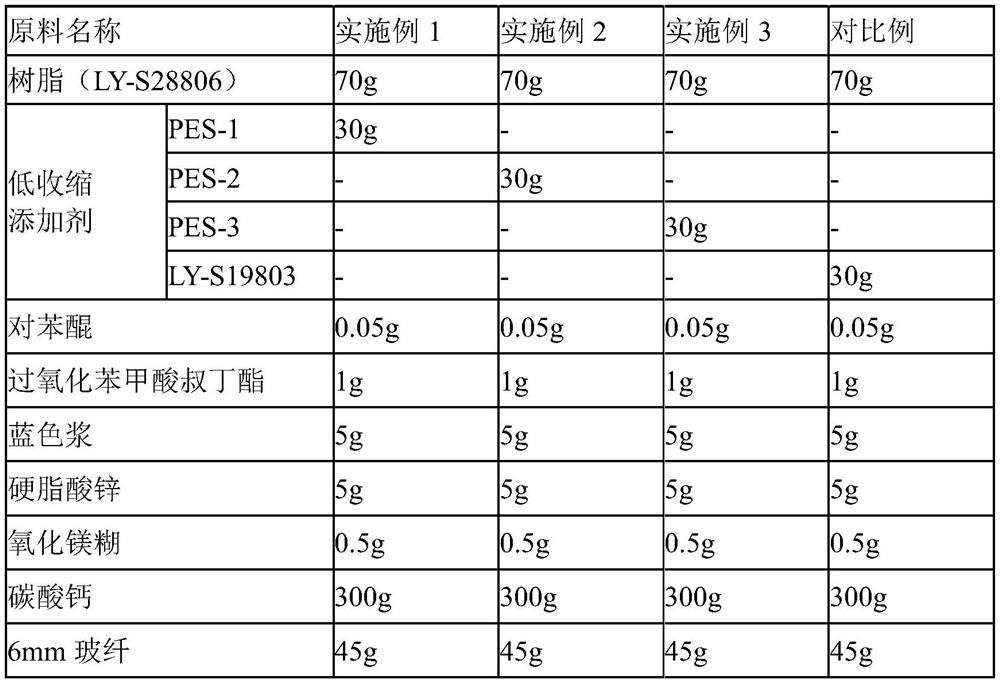

Embodiment 1

[0024] In a 1L four-necked flask equipped with a thermometer, a stirrer, a nitrogen inlet tube and a reflux condenser, add 25g of pentaerythritol and 620g of ε-caprolactone in sequence, slowly raise the temperature to 140°C under the protection of nitrogen, and then dropwise add 1.9g of octanoic acid Sn catalyst, after the dropwise addition, reflux reaction in the range of 150°C-155°C for 5 hours. Cool down to 90°C, add 0.1g of tert-butylcatechol, stir evenly, and after the polymerization inhibitor is completely dissolved, add 326g of styrene to dilute. Cool and filter to obtain a near-water white transparent viscous liquid, which is a saturated polyester low shrinkage additive (named PES-1).

Embodiment 2

[0026] In a 1L four-neck flask with a thermometer, a stirrer, a nitrogen inlet tube and a reflux condenser, add 33g of ditrimethylolpropane (i.e. bis(trimethylol)propane)=, 594gε-caprolactone , under the protection of nitrogen, the temperature was slowly raised to 150°C, and then 1.5g of stannous octoate catalyst was added dropwise. After the dropwise addition, the mixture was refluxed for 8 hours in the range of 150°C-155°C. Cool down to 100°C, add 0.1g of tert-butylcatechol, stir evenly, and after the polymerization inhibitor is completely dissolved, add 337g of styrene to dilute. Cool and filter to obtain a near-water white transparent viscous liquid, which is a saturated polyester low shrinkage additive (named PES-2).

Embodiment 3

[0028] In a 1L four-neck flask equipped with a thermometer, a stirrer, a nitrogen inlet tube and a reflux condenser, 28g of dipentaerythritol and 628g of ε-caprolactone were sequentially added, and the temperature was slowly raised to 170°C under the protection of nitrogen, and then 2.0g of Stannous octoate catalyst, after the dropwise addition, reflux reaction in the range of 150°C-155°C for 8 hours. Cool down to 90°C, add 0.12g of tert-butylcatechol, stir evenly, and after the polymerization inhibitor is completely dissolved, add 392g of styrene to dilute. Cool and filter to obtain a near-water white transparent viscous liquid, which is a saturated polyester low shrinkage additive (named PES-3).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com