Method for preparing cycloastragenol by double-enzyme compounding conversion of astragaloside

A technology of astragaloside IV and cycloastragenol, which is applied in the field of preparation of cycloastragenol, can solve the problems of unclear mechanism of enzyme action, low tolerance of enzyme substrate, and low efficiency of separation and purification, and achieve high product yield and bottom High drug tolerance and high separation and purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

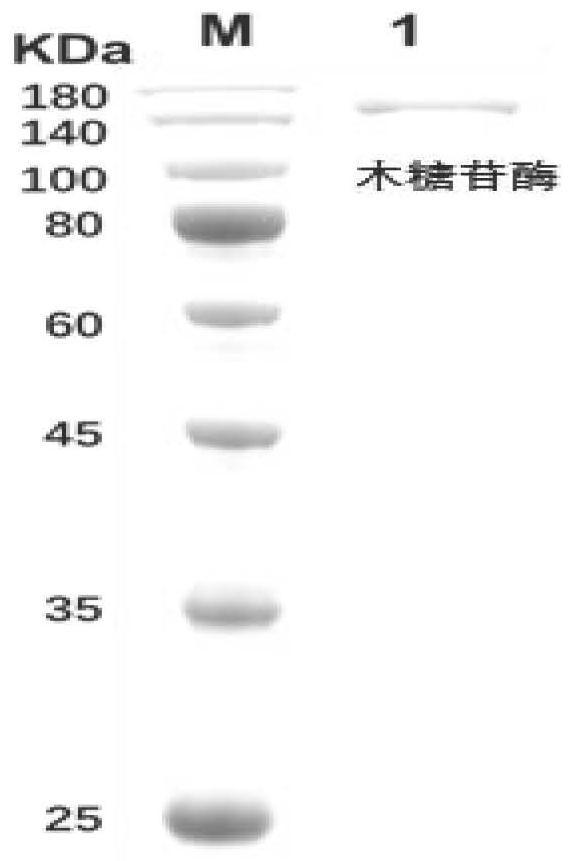

[0086] The preparation of embodiment 1 xylosidase Xyl-G9

[0087] Insert the recombinant Pichia pastoris GS115-Xyl-G9 with the Xyl-G9 gene SEQ ID NO.3 into 1L of BMMG medium and culture it at 30°C and 220r / min for 12h; then the enriched bacteria The body was washed and inserted into 5LBMMY medium, cultured at 30°C and 220r / min, and 1% volume fraction of methanol was added every 24h to induce enzyme production. After culturing for 5 days, the fermentation broth was filtered to remove bacteria, and the obtained fermentation supernatant was purified by a nickel column to obtain 100 mL of pure recombinant xylosidase Xyl-G9. The product of 150KDa was detected by electrophoresis. Electrophoresis results see figure 1 .

Embodiment 2

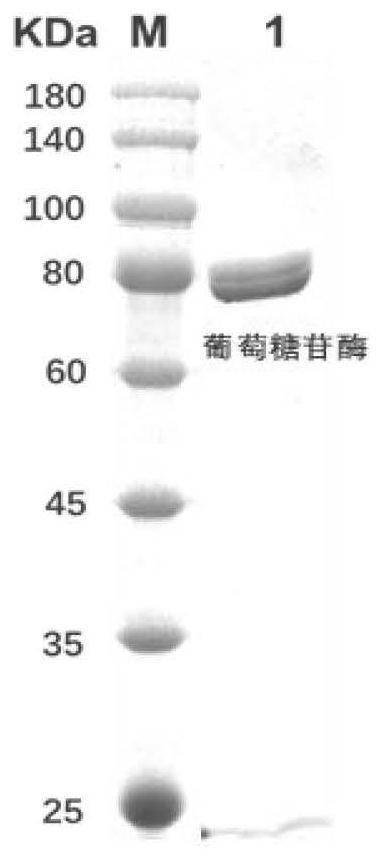

[0088] The preparation of embodiment 2 glucosidase Bgcm

[0089] The recombinant Escherichia coli BL21-Bgcm containing the Bgcm gene was inoculated into 1 L of LB medium, and the fermentation was induced for 24 hours at 20°C in IpTG containing 1‰ volume fraction. After the fermentation, the recombinant cells were collected at 6000r / min, and the cells were resuspended using 200mL of 20mM pH 6.0 phosphate buffer, then ultrasonically disrupted and centrifuged to obtain 200mL of glucosidase Bgcm crude enzyme solution, and then purified by a nickel column to obtain 50mL of Pure Glucosidase Bgcm. The product of 78KDa was detected by electrophoresis. Electrophoresis results see image 3 .

Embodiment 3

[0090] The preparation of embodiment 3 composite enzymes

[0091] 100 mL of pure recombinant xylosidase Xyl-G9 and 50 mL of pure glucosidase Bgcm were freeze-dried respectively to obtain 252 mg of powdery recombinant xylosidase Xyl-G9 and 356 mg of powdery recombinant xylosidase Bgcm. Then get 200mg of the above-mentioned powdery xylosidase Xyl-G9 and 100mg of the above-mentioned powdery glucosidase Bgcm and mix to prepare 300mg of compound enzyme.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com