A self-supporting three-dimensional nano-graded porous high-entropy alloy electrolyzed water material and its preparation method

A three-dimensional nano, high-entropy alloy technology, applied in the direction of electrolysis components, electrolysis process, electrodes, etc., can solve the problems affecting the number, stability and conductivity of catalyst active sites, and achieve simple and controllable processing temperature, low price, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A method for preparing a flexible nanoporous metal oxide negative electrode for a lithium ion battery, comprising the following steps:

[0028] (1) Preparation of alloy powder: the alloy powder is composed of the following components by atomic percentage: Mn: 60% to 70%; Ni: 5% to 20%; Cu: 5% to 10%; transition metal A: 5% ~10%; transition metal B: 5%~15%, put alcohol as a dispersant and alloy powder together in a high-energy ball mill for mechanical alloying, and vacuum dry after ball milling to obtain evenly dispersed alloy powder;

[0029] (2) Preparation of casting solution: Add the alloy powder prepared in step (1) together with the solvent into a three-necked flask for mechanical stirring; after mechanical stirring for 10-30 minutes, add porogen and thickener and continue stirring for 12-24 hours, Obtain a casting solution in which alloy powder, porogen and thickener are uniformly dispersed in a solvent;

[0030] (3) Scraping film: Pour the casting solution obtai...

Embodiment 1

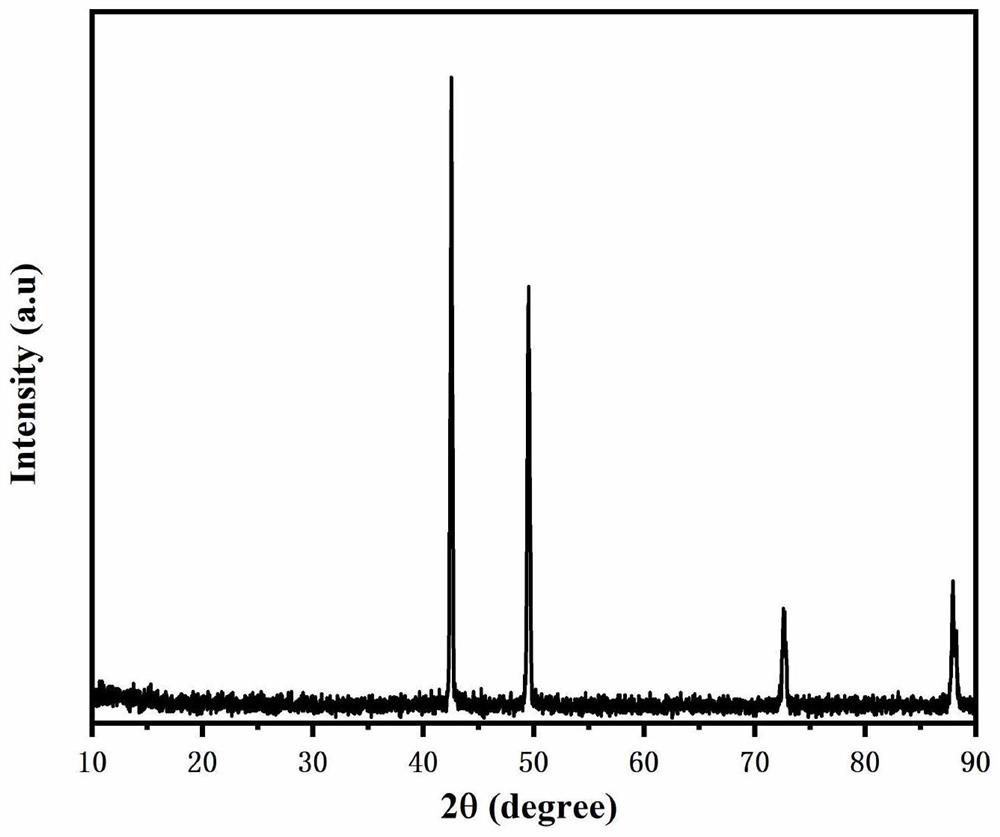

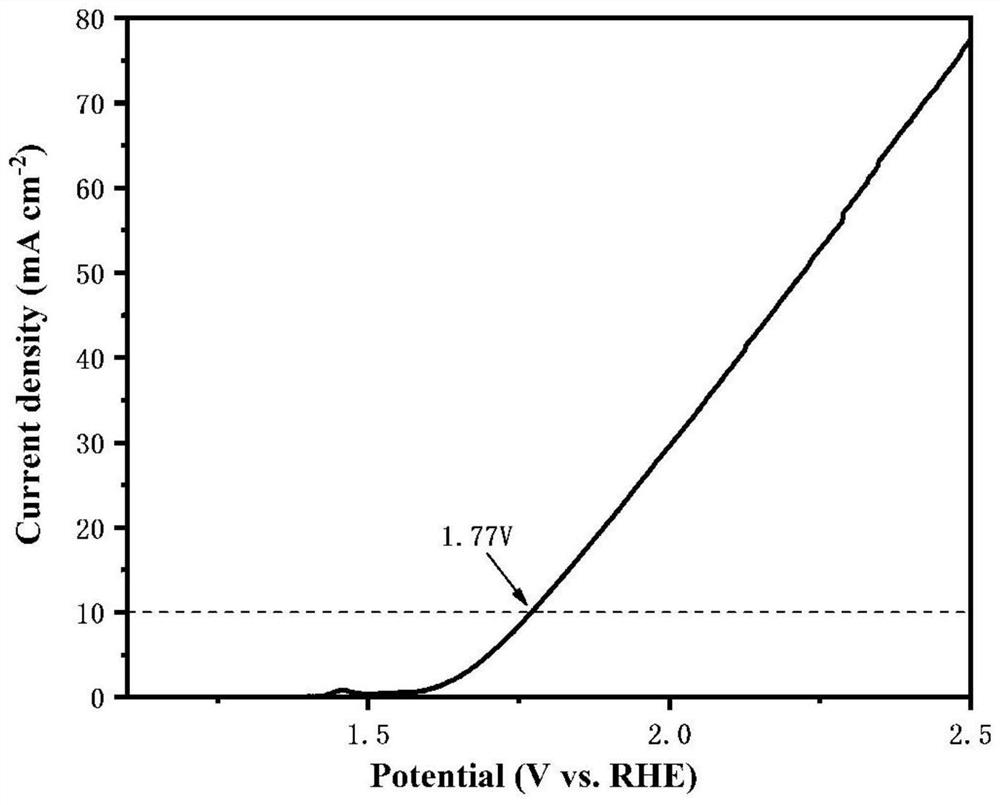

[0034] A self-supporting three-dimensional nano-graded hole high-entropy alloy electrolyzed water material and a preparation method thereof, comprising the following steps:

[0035] (1) Preparation of alloy powder: Mix the powders of each component with atomic ratio: Mn: 68%; Ni: 8%; Cu: 8%; Fe: 8%; Co: 8% Add 25g of alloy powder raw material into the ball mill, control the mass ratio of ball to material to 5:1, the ball milling time is 24h, the ball milling speed is 200r / min, and 15ml of alcohol is used as a dispersant to prepare uniformly dispersed alloy powder;

[0036] (2) Preparation of film casting solution: 20 g of alloy powder prepared in step (1) and 25 g of solvent are added together in a three-necked flask for mechanical stirring; after mechanical stirring for 10 min, 3 g of porogen and 0.5 g of thickener are added to continue stirring for 24 hours , obtain alloy powder, porogen and thickener in the casting film liquid that disperses uniformly in solvent, wherein po...

Embodiment 2

[0046] A self-supporting three-dimensional nano-graded hole high-entropy alloy electrolyzed water material and a preparation method thereof, comprising the following steps:

[0047] (1) Preparation of alloy powder: Mix the powders of each component with the atomic ratio: Mn: 60%; Ni: 10%; Cu: 10%; Ti: 10%; Add 25g of alloy powder raw material into the ball mill, control the mass ratio of ball to material to 10:1, the ball milling time is 12h, the ball milling speed is 150r / min, and 10ml of alcohol is used as a dispersant to prepare evenly dispersed alloy powder;

[0048] (2) Preparation of casting solution: 15 g of alloy powder prepared in step (1) and 20 g of solvent are added together in a three-necked flask for mechanical stirring; after mechanical stirring for 10 min, 2.5 g of porogen and 0.5 g of thickener are added to continue stirring for 12 Hour, obtain alloy powder, porogen and thickener to disperse uniformly in the casting solution in solvent, wherein porogen is poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com