Water-resistant environment-friendly fiber filtering material and preparation method thereof

A filter material and nanofiber technology, applied in the field of water-resistant environmental protection fiber filter material and its preparation, can solve the problems of poor water resistance, loss of fiber structure, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

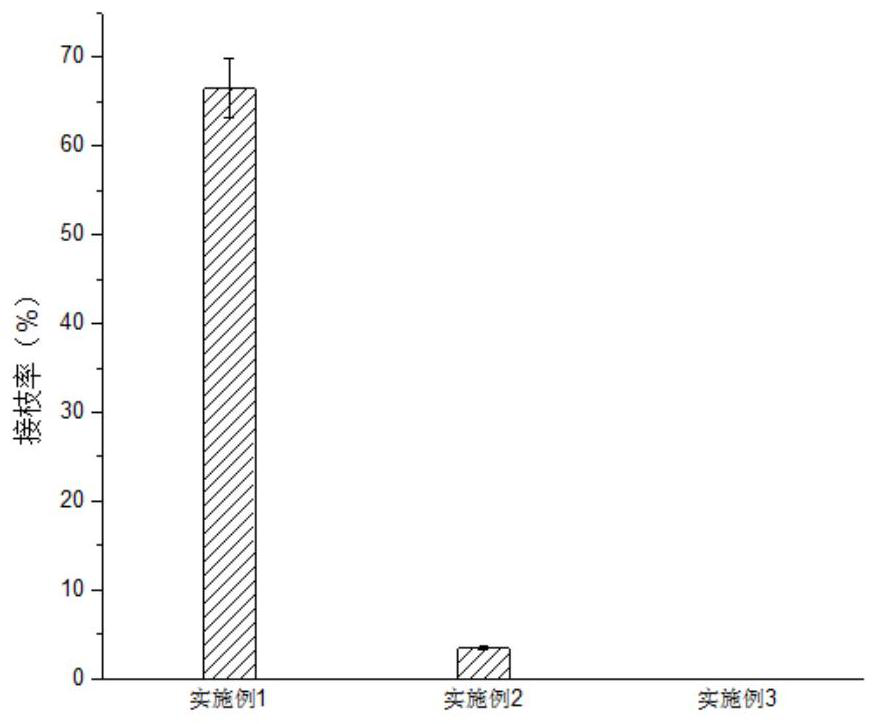

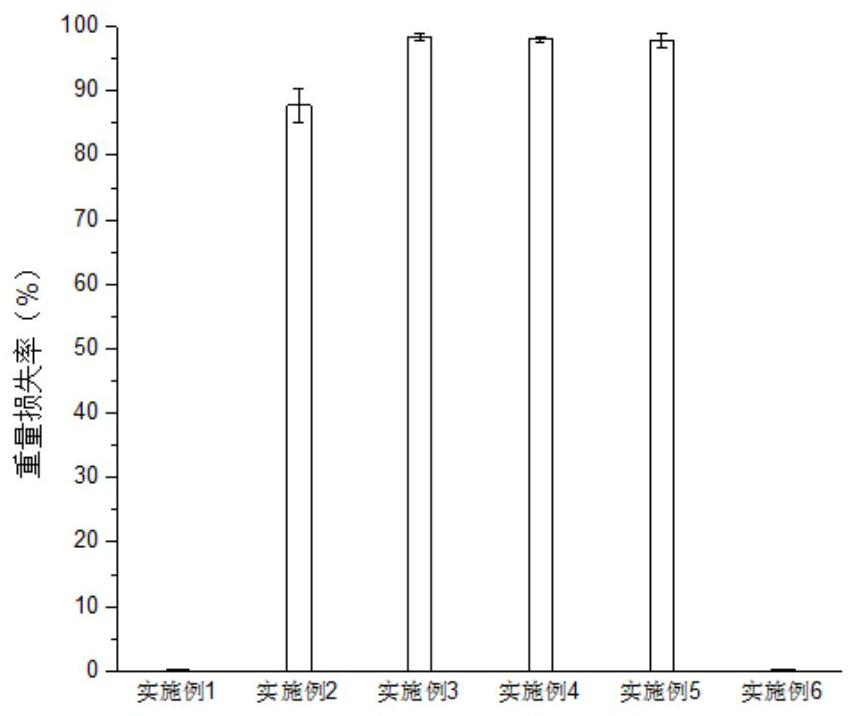

Embodiment 1

[0035] 1. A method for preparing water-resistant polyvinyl alcohol nanofibers, comprising the following steps:

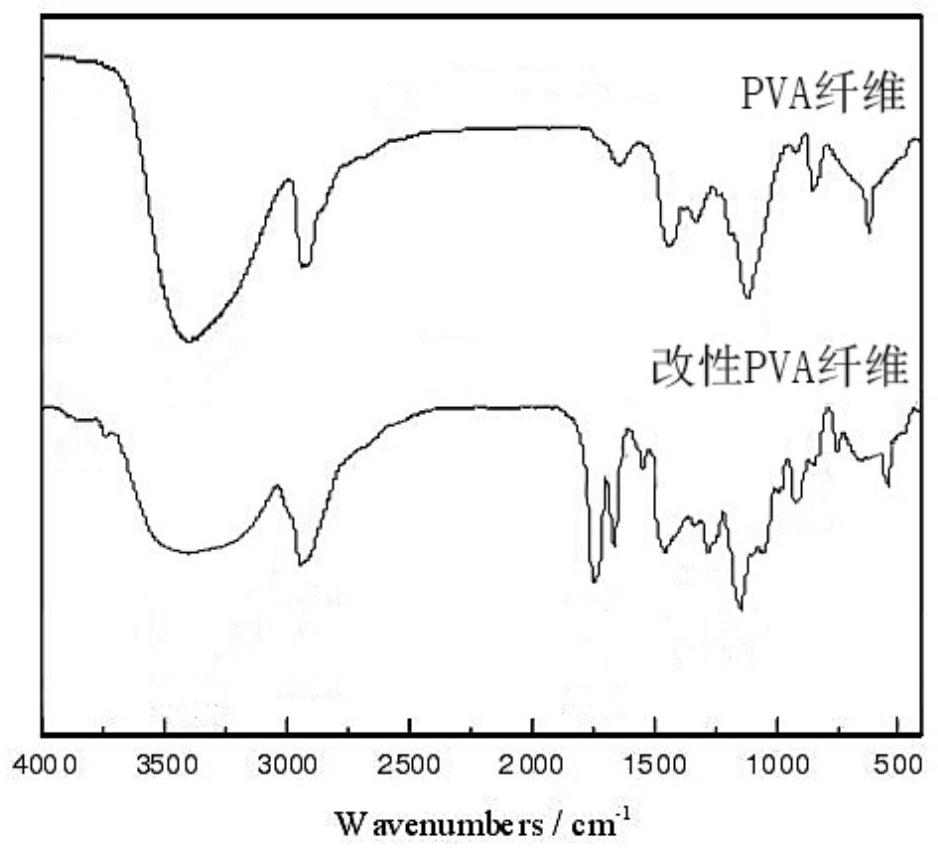

[0036] Weigh 9g of polyvinyl alcohol (1799, degree of alcoholysis 98% (mol / mol)) and mix with 120mL of distilled water, heat to 85°C with stirring, and keep warm for 1.5h to obtain a polyvinyl alcohol fiber solution; Add 0.826g(-)-epigallocatechin and 29.7g L-2-amino-3-methylbutyric acid, heat to 105°C, stir for 1.2h, let stand and cool to obtain surface-modified polyvinyl alcohol The fiber solution is precipitated with acetone, and the product is filtered, and the filtrate is repeatedly washed with distilled water for 3 times, dried and ground. Take the modified polyvinyl alcohol, add water at 92°C and stir to dissolve, prepare 150g 8wt% modified polyvinyl alcohol fiber aqueous solution as the electrospinning liquid, according to the ambient temperature of 25°C, humidity of 28%, receiving distance of 18cm, spinning voltage Electrospinning under the condition of 26...

Embodiment 2

[0040] No (-)-epigallocatechin was added to the surface modification of the polyvinyl alcohol fibers, and the remaining parts were exactly the same as in Example 1.

Embodiment 3

[0042]When carrying out surface modification to polyvinyl alcohol fibers, no L-2-amino-3-methylbutyric acid was added, and the rest were exactly the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com