Polyamide fiber

A technology of polyamide fiber and montmorillonite, applied in the field of polyamide fiber, can solve problems such as poor wear resistance, and achieve the effects of improving efficiency, improving the effect of tamping, and improving the efficiency of defoaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

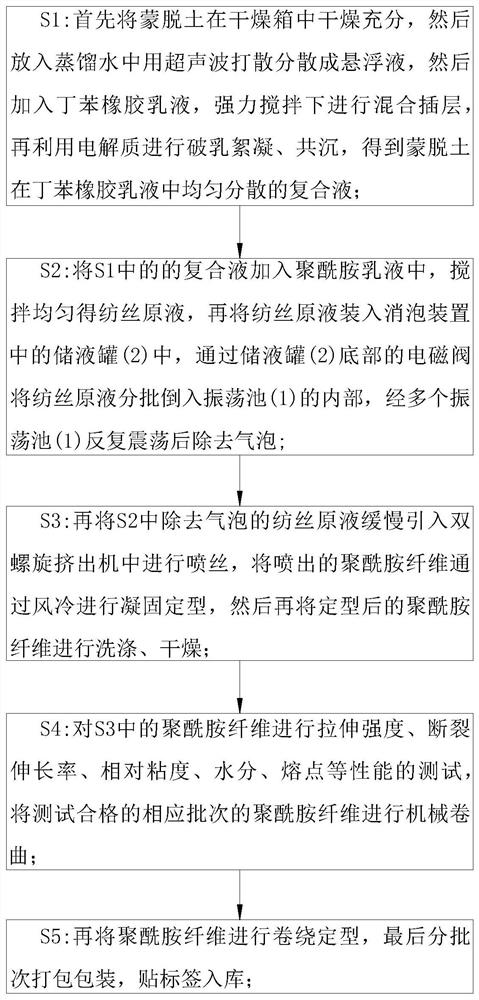

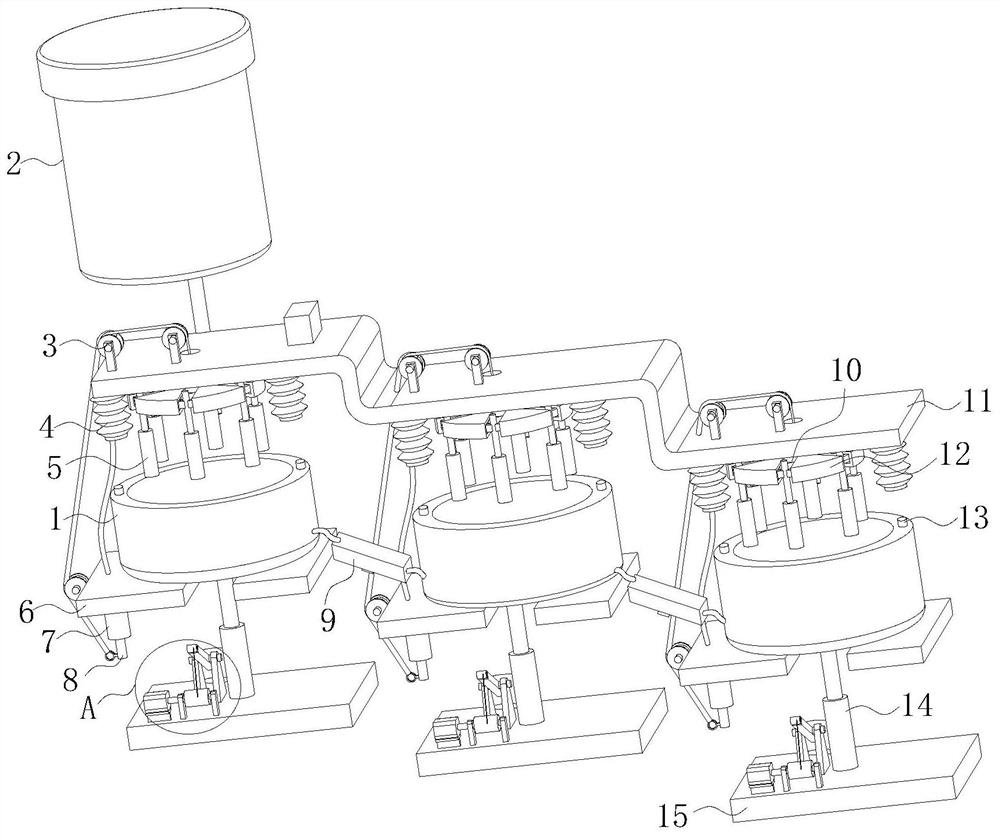

Method used

Image

Examples

Embodiment approach

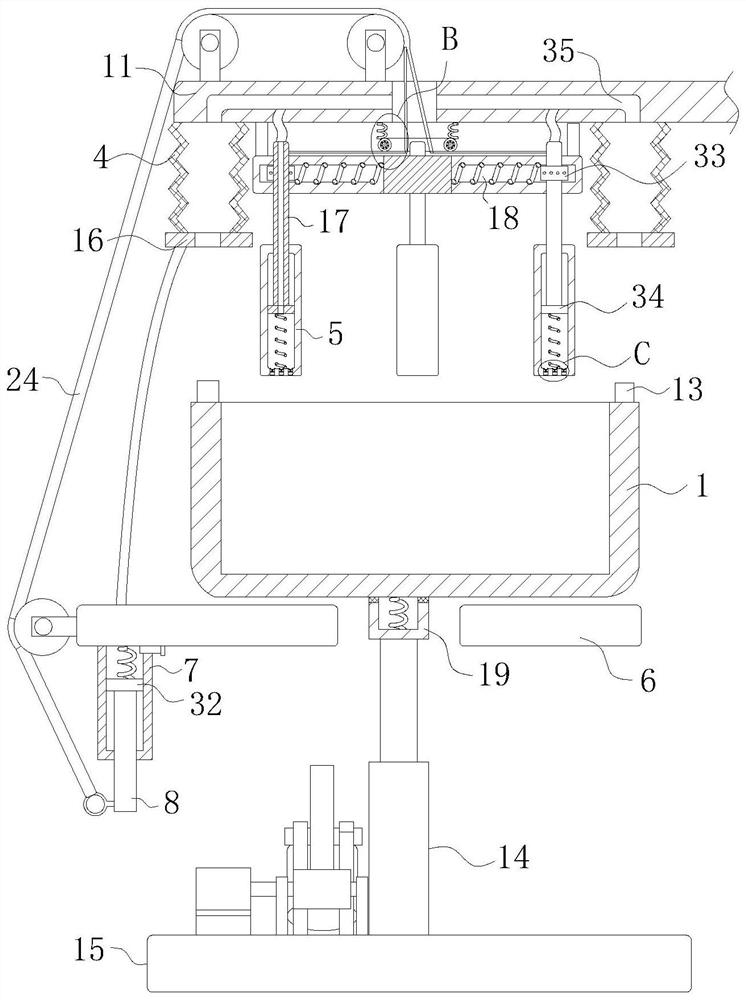

[0049] As an embodiment of the present invention, the bottom of the movable tube 5 is evenly provided with an air suction groove 28; the middle part of the air suction groove 28 is fixedly provided with a support rod 27; It is fixedly connected to the bottom of the sealing plate 36; the one-way sealing plate 36 is a funnel-shaped structure; the bottom end of the one-way sealing plate 36 is clamped on the upper port of the air suction groove 28; the air suction groove 28 is close to The position of the bottom end is fixedly provided with a waterproof breathable membrane 29; during work, when the oscillation pool 1 moves up, the movable tube 5 will be squeezed, and the gas below the second piston plate 34 is squeezed, and the gas located under the second piston plate 34 The gas below has a tendency to diffuse to the surroundings, but when the gas diffuses downward, it will be blocked by the one-way sealing plate 36, and then the gas can only diffuse upward. When the oscillation p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com