A skin-friendly fabric that is easy to breathe and wick away sweat and its preparation method

A fabric and surfactant technology, applied in dyeing, fabric surface trimming, physical treatment, etc., can solve problems such as poor perspiration ability, restricted air permeability, and decreased thermal comfort of clothing, so as to reduce moisture absorption and improve Good quality of life, fabric appearance and style

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

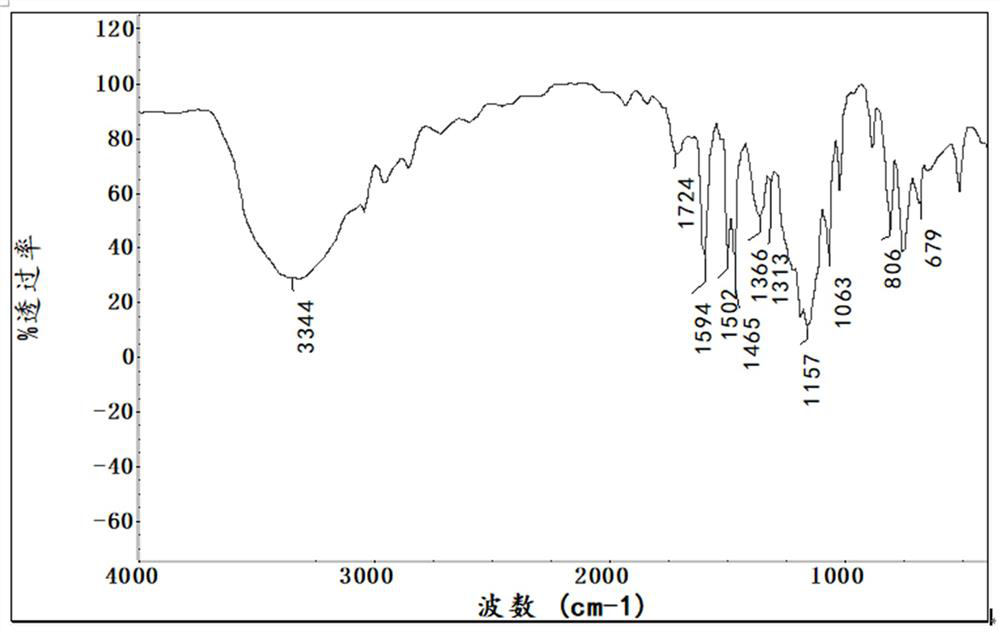

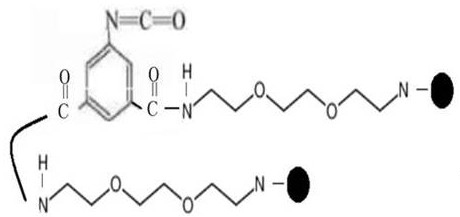

Image

Examples

Embodiment 1

[0037] A skin-friendly fabric that is easy to ventilate and sweat and a preparation method thereof, the operation of the method is as follows:

[0038] Step 1: Fabric blending, knitting and weaving 25kg of modified cotton fibers, 2kg of Cloomax fibers, 0.5kg of Tencel fibers, 4kg of Modal fibers and 2kg of spandex fibers using a large circular knitting machine to obtain fabrics;

[0039] Step 2: fabric finishing, add 0.5kg surfactant, 0.1kg edetate ammonium, 0.05kg sodium hydroxide to 80kg water and mix evenly, finally add 0.5kg finishing agent and mix evenly, put the obtained fabric into the solution , slowly raise the temperature to 80°C, keep it warm for 20 minutes, take it out in cold water, soak it for 5 minutes, and wring it dry;

[0040] Step 3: Fabric dyeing, dyeing the fabric, and drying at 50°C for 5 hours after dyeing;

[0041]Step 4: The fabric is shaped, the fabric is baked in the setting machine at a high temperature of 150 for 15s, and the speed is 12m / min, to ...

Embodiment 2

[0051] A skin-friendly fabric that is easy to ventilate and sweat and a preparation method thereof, the operation of the method is as follows:

[0052] Step 1: Fabric blending, knitting and weaving 28kg of modified cotton fibers, 4kg of Cloomax fibers, 2.3kg of Tencel fibers, 6kg of Modal fibers and 3kg of spandex fibers using a large circular knitting machine to obtain fabrics;

[0053] Step 2: fabric finishing, add 0.8kg surfactant, 0.3kg edetate ammonium, 0.12kg sodium hydroxide to 90kg water and mix evenly, finally add 0.9kg finishing agent and mix evenly, put the obtained fabric into the solution , slowly raise the temperature to 85°C, keep it warm for 35 minutes, take it out in cold water, soak it for 10 minutes, and wring it dry;

[0054] Step 3: Dyeing the fabric, dyeing the fabric, and drying at 60°C for 6 hours after dyeing;

[0055] Step 4: The fabric is shaped, the fabric is baked in the setting machine at a high temperature of 160 for 25s, and the speed is 15m / mi...

Embodiment 3

[0065] A skin-friendly fabric that is easy to ventilate and sweat and a preparation method thereof, the operation of the method is as follows:

[0066] Step 1: Fabric blending, knitting and weaving 30kg of modified cotton fibers, 8kg of Cloomax fibers, 3kg of Tencel fibers, 8kg of Modal fibers and 4kg of spandex fibers using a large circular knitting machine to obtain fabrics;

[0067] Step 2: fabric finishing, add 1.2kg surfactant, 0.6kg EDTA, 0.2kg sodium hydroxide to 110kg water and mix evenly, finally add 1.6kg finishing agent and mix evenly, put the obtained fabric into the solution , slowly raise the temperature to 95°C, keep it warm for 45 minutes, take it out in cold water, soak it for 15 minutes, and wring it dry;

[0068] Step 3: Dyeing the fabric, dyeing the fabric, and drying at 70°C for 10 hours after dyeing;

[0069] Step 4: The fabric is shaped, the fabric is baked in the setting machine at a high temperature of 180 for 35s, and the speed is 18m / min, to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com