Vacuum atmosphere melting furnace for high purity magnesium and melting process thereof

A melting furnace and vacuum technology, applied in the direction of furnaces, crucible furnaces, furnace components, etc., can solve the problems of low melting efficiency of melting equipment, unguaranteed safety, long preparation process cycle, etc., to achieve favorable precipitation, significant energy saving effect, highly operable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

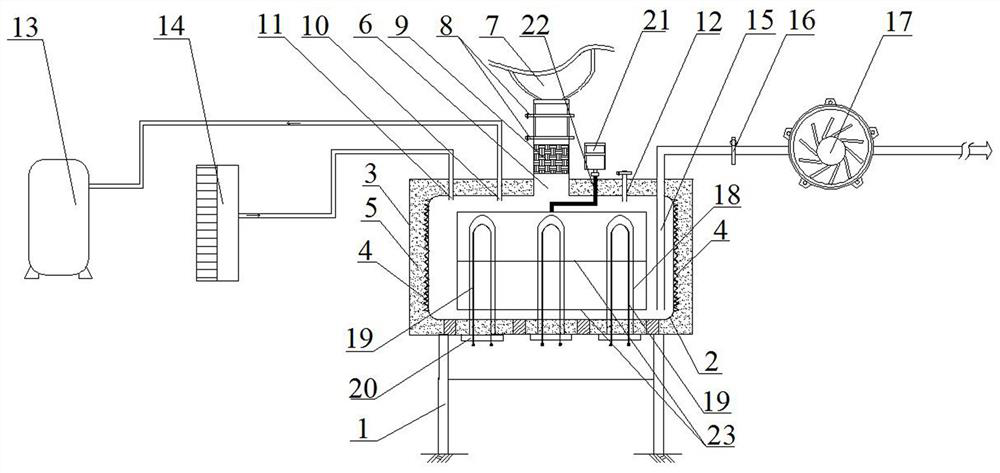

[0033] Below in conjunction with accompanying drawing, the present invention is described in further detail:

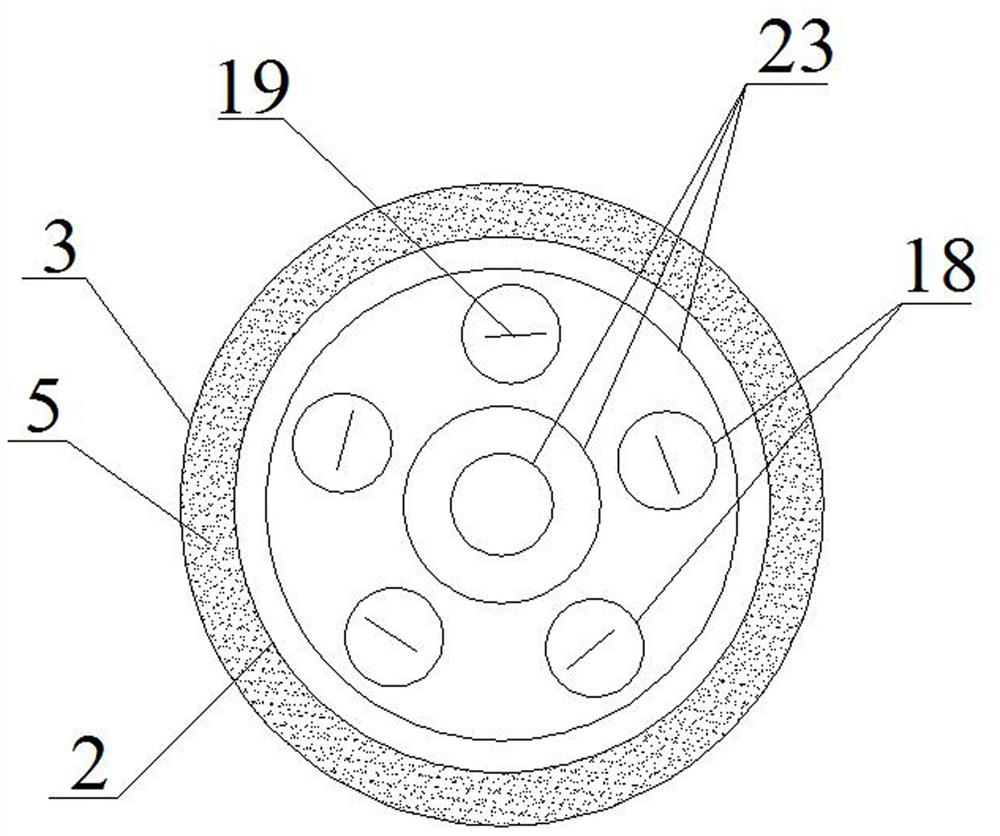

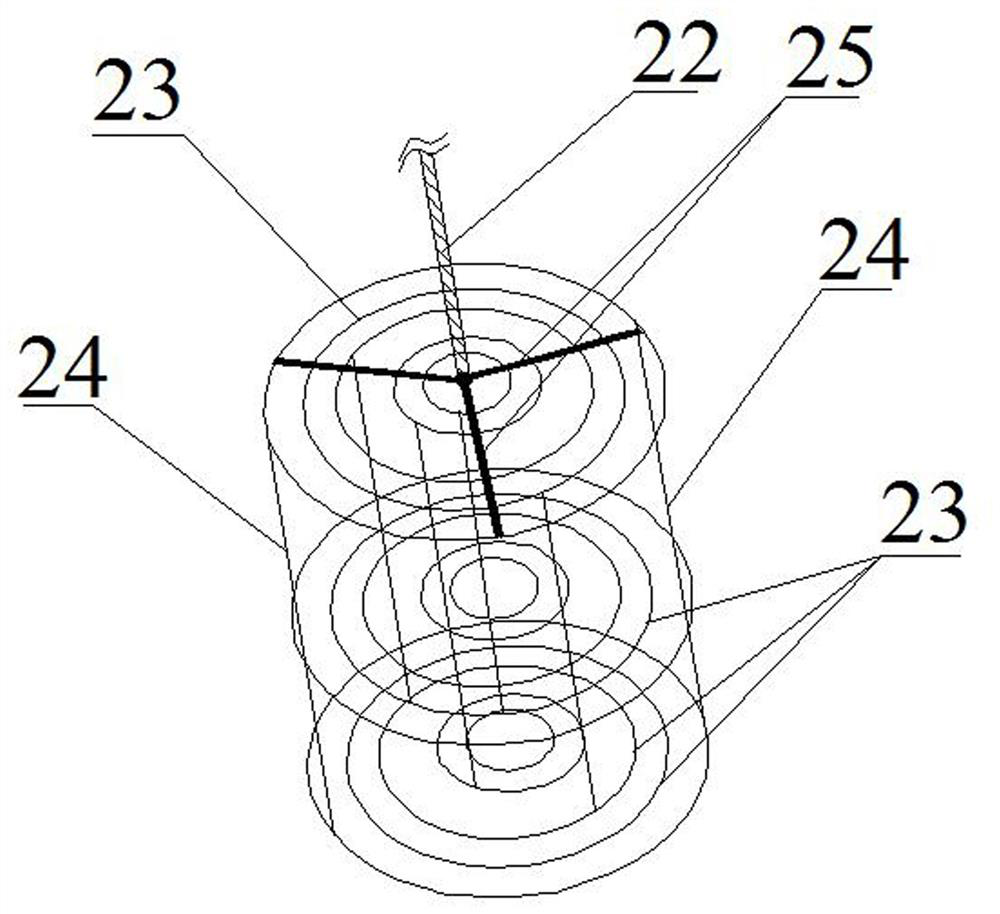

[0034] As shown in the figure, a vacuum atmosphere melting furnace for high-purity magnesium includes a control mechanism, a support frame body 1 and a vertical double-layer shell arranged above the support frame body 1, and the inside of the vertical double-layer shell The main heating assembly is provided, and the vertical double-layer casing includes an inner casing 2 and an outer casing 3, and a resistance wire 4 for auxiliary heating is wound on the outer surface of the side wall of the inner casing 2, and the inner casing 2 and the outer casing 3 are also filled with thermal insulation material 5, the main heating assembly and the resistance wire 4 are connected to the control mechanism, and a feed inlet 6 is opened on the top of the vertical double-layer casing, and the feed inlet 6 Set at the top center of the vertical double-layer shell, the feed port 6 is do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com