Method for determining catalyst coating and ash distribution on automobile particulate matter catcher

A particle trap and catalyst coating technology, which is used in material analysis, instruments, and measurement devices using wave/particle radiation, and can solve problems such as accumulated ash shedding, complex pore structure, and inability to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: A method for measuring the catalyst coating and ash distribution on the automotive particulate filter

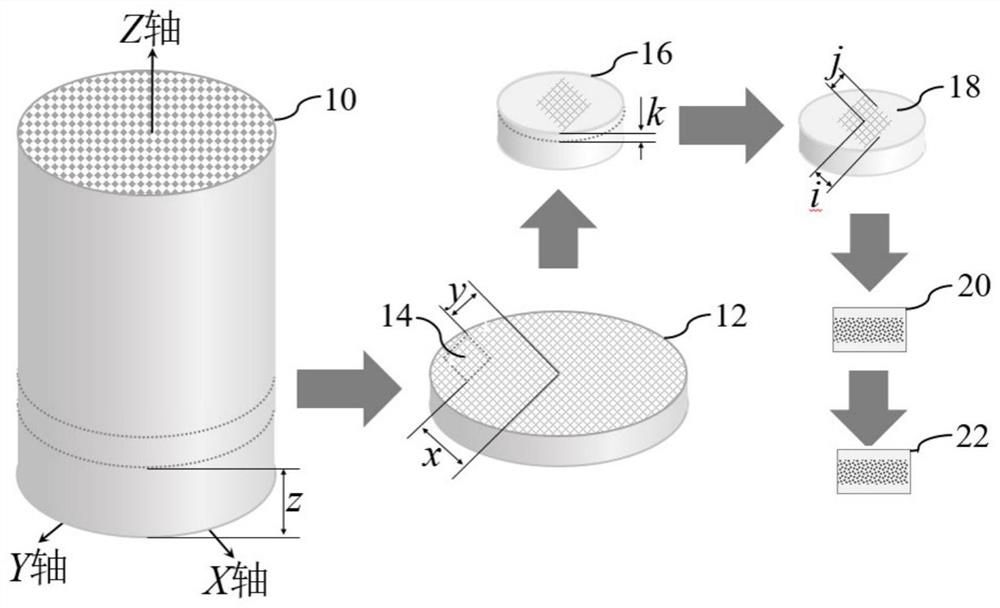

[0031] see figure 1 , the steps included in this embodiment are specifically as follows:

[0032] (1) Marking and sampling

[0033] The origin O is the center of the air intake end face of the automotive particle filter 10, the X-axis passes through the origin on the air intake end face and along the arrangement direction of the quadrangular prism hole array, and the X-axis passes through the origin on the air intake end face and is perpendicular to the X-axis. On the Y axis, the ray pointing from the origin to the gas outlet along the quadrangular prism channel is the positive direction of the Z axis.

[0034] Define the side of the intercepted sample parallel to and close to the YOZ coordinate plane as the first side, the distance between the first side and the YOZ coordinate plane is x, and the distance between the center of the analysis area and the f...

Embodiment 2

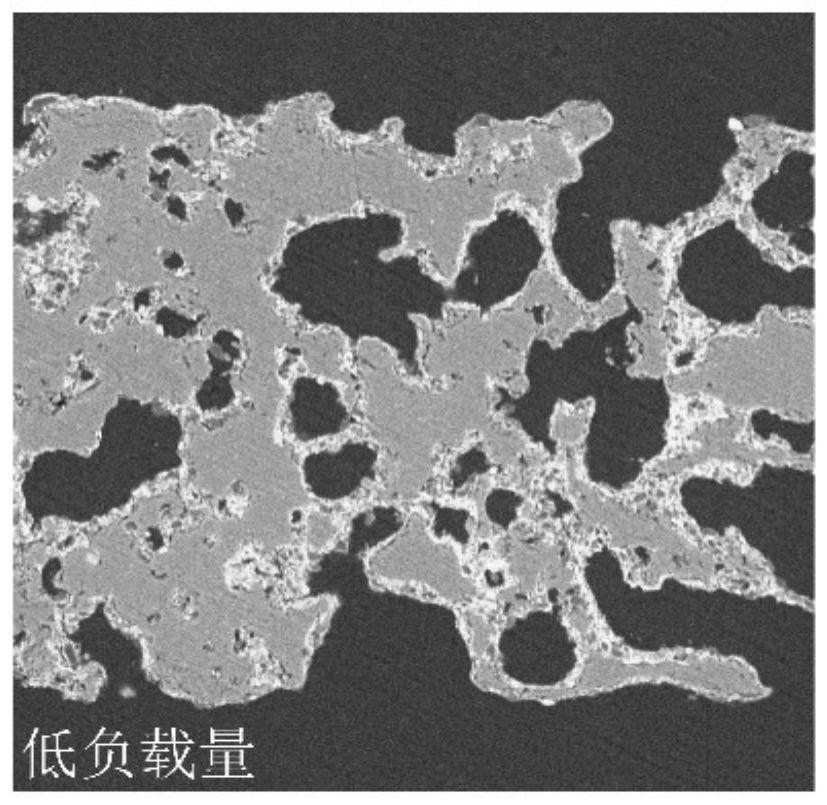

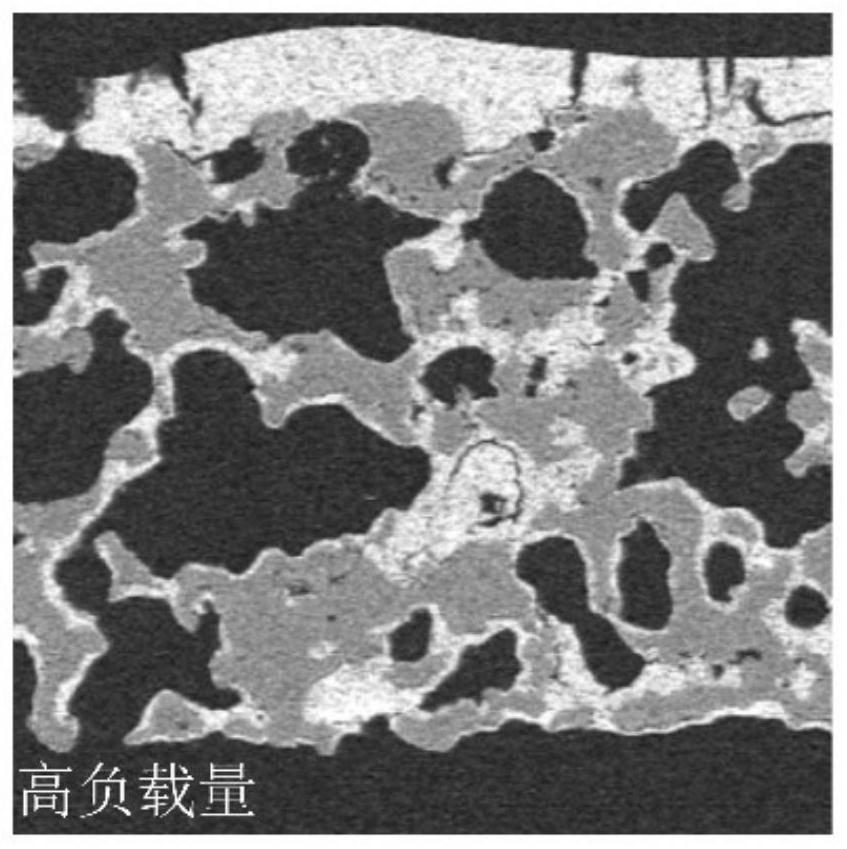

[0047] Example 2: Analysis of Rare Earth Oxide Coating Distribution

[0048] This embodiment includes the following steps:

[0049] Select 2 automotive particulate matter traps with the same catalyst coating, containing rare earth composite oxides, and different loads, and cut cube samples at (-25, 30, 20) spatial positions as described in the steps of Example 1, and try The sample side length is 8mm. Weigh 20 grams of the vacuum-free clear cold mounting set whose main component is epoxy resin and 10 grams of curing agent into the same disposable paper cup, stir thoroughly with a bamboo stick, and pour it into two 12 mm diameter cups after standing for 5 minutes , in a rubber mold with a depth of 12 mm. Put the two intercepted samples vertically into the rubber mold to ensure that the quadrangular prism channels are completely filled with resin, and take out the cold-mounted samples after standing for 80 minutes.

[0050] Choose 180-mesh water sandpaper, and the grinding di...

Embodiment 3

[0053] Example 3: Aluminum Oxide Coating Distribution

[0054] This embodiment includes the following steps:

[0055] Select an automobile particulate filter containing aluminum oxide coating, and cut cube samples at (40,-20,50) spatial positions according to the steps of Example 1, and the side length of the sample is 6 mm. Weigh 10 grams of the vacuum-free clear cold mounting set whose main component is epoxy resin and 5 grams of curing agent into the same disposable paper cup, stir thoroughly with a bamboo skewer, let it stand for 3 minutes, pour it into a 10 mm diameter, deep for 10 mm rubber molds. Put the intercepted sample vertically into the rubber mold to ensure that the quadrangular prism channels are completely filled with resin, and take out the cold-mounted sample after standing for 60 minutes.

[0056] Use 200-mesh water sandpaper, and the grinding disc rotates at 400 rpm, and grind the grinding surface of the cold-mounted sample until it is smooth, and measure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com