Optical frequency comb generation device, production device preparation method and production method

A technology for generating a device and an optical frequency comb, which is applied in the field of optical frequency combs and can solve problems such as affecting the quality of optical frequency combs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

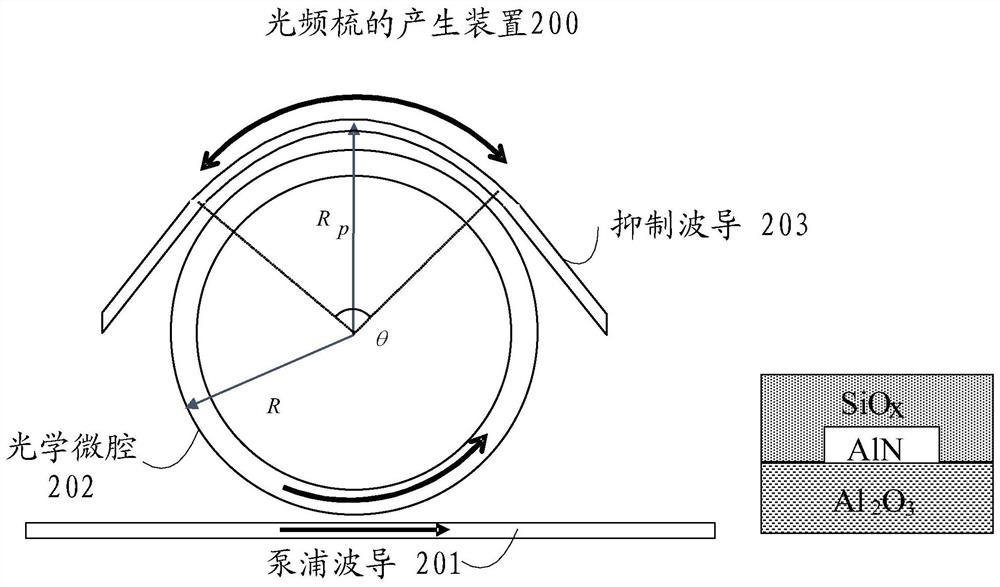

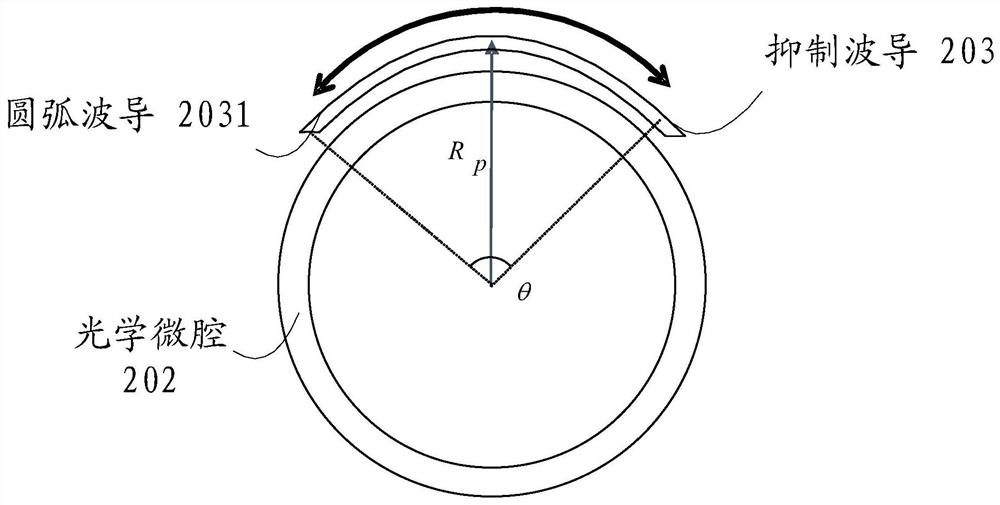

[0044] figure 2 A schematic structural diagram of an optical frequency comb generating device 200 provided in Embodiment 1 of the present application, as shown in figure 2 As shown, this embodiment mainly includes:

[0045] The substrate, and the pumping waveguide 201, suppressing waveguide 203 and optical microcavity 202 grown on the substrate.

[0046] figure 2 It is a top view of the generating device 200 of the optical frequency comb. Therefore, the substrate is not shown in the figure. In fact, the substrate is a layer of substrate material at the bottom of the pumping waveguide 201 , suppressing waveguide 203 and optical microcavity 202 . The substrate can be made of semiconductor materials, such as SiO 2 The material may also be a crystal material, such as a sapphire material. The pumping waveguide 201, the suppressing waveguide 203 and the optical microcavity 202 are all connected to the substrate, grown and etched on the substrate. In a possible implementation m...

Embodiment 2

[0058] Such as Figure 5 As shown, the embodiment of the present application also provides a preparation method of an optical frequency comb generation device, including:

[0059] S501: growing a crystal material thin film on a substrate.

[0060] Any common substrate can be used, such as semiconductor material substrate, crystal material substrate, silicon substrate, etc., and any common preparation method can be used to grow crystal material film on the substrate, such as metal organic compound chemical vapor phase Deposition (Metal-organic Chemical Vapor Deposition, MOCVD), sputtering growth, etc. Any of the commonly used crystal materials used to manufacture optical microcavities can be used to grow the above-mentioned crystal material thin films, for example, silicon nitride (Si 3 N 4 ), aluminum nitride (AlN), silicon (Si), calcium fluoride (CaF 2 ), magnesium fluoride (MgF 2 ) or thin film lithium niobate (LiNbO 3 )Wait.

[0061] Generally speaking, after growing...

Embodiment 3

[0086] Such as Figure 9 As shown, the embodiment of the present application also provides a method for generating an optical frequency comb, including:

[0087] S901: Injecting an optical signal into the pumping waveguide, where the optical signal is coupled to the optical microcavity by the pumping waveguide.

[0088] Here, the incident optical signal is generally a single-frequency optical signal.

[0089] S902: The part of the optical signal in the optical microcavity whose frequency is the Raman frequency is coupled to the suppression waveguide by the optical microcavity; the Raman frequency is generated when the Raman scattering effect occurs in the optical microcavity Frequency of scattered light.

[0090] Due to the good phase matching between the suppression waveguide and the optical microcavity at the Raman frequency, when the Raman scattering effect occurs in the optical microcavity, most of the frequency in the optical signal is the part of the Raman frequency, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com