Regeneration method of silicon electrode part of semiconductor equipment etching device

An etching device and a technology for silicon electrodes, applied in the field of cleaning, can solve the problems of long etching time, roughness, uneven surface of silicon substrates, etc. of silicon substrates, and achieve the effect of avoiding uneven etching or roughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

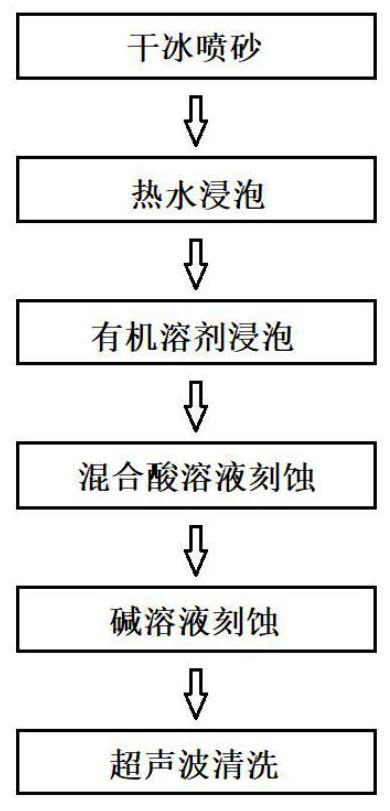

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

[0032] see Figure 1 to Figure 3 , the method for regenerating the silicon electrode part of the semiconductor equipment etching device in this embodiment, comprises the following steps:

[0033] Step (1), dry ice blasting;

[0034] The silicon electrode is sprayed with dry ice (CO2) particles to remove residues or deposits on the surface. The air pressure used is 0.3Mpa, the ice output is 0.2kg / min, and the spray is continued for 15 minutes;

[0035] Step (2), soaking in hot water;

[0036] Put the silicon electrode into the hot water tank, remove or loosen the metallized organic matter attached to the surface by wetting the surface attachment of the silicon electrode, the temperature of the hot water is 70±2°C, and the soaking time in hot water is 20 minutes;

[0037] Step (3), soaking in an organic solvent;

[0038] Put the silicon electrode into the organic sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com