Method for producing wheat seedling juice through color protection liquid soaking and low-temperature squeezing

A technology of color protection liquid and wheatgrass juice, which is applied in the field of food processing, can solve the problems of disappearance of beneficial ingredients, no wheatgrass, adjustment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment one low temperature pressing product

[0035] (1) Washing: take 30kg of young wheat seedlings within 4-6 months, send them into the washing tank through the conveyor belt, wash them under the disturbance of the air bubbles at the bottom of the washing tank, and then send them to the spray channel for washing again through the conveyor belt; When washing in the pool, the mass ratio of washing water to wheat leaves is 3:1, the water temperature is 5°C, the washing time is 5 minutes, and the water is pure water; when washing in the spray channel, the spray washing time is 5 minutes, the water temperature is 5°C, and the water spray volume is 0.2 kg / kg, water is pure water;

[0036] (2) Cutting: the soaked wheat seedlings are cut into strips or fragments of about 1-3cm by a cutting machine, and quickly transferred to the color protection pool for soaking;

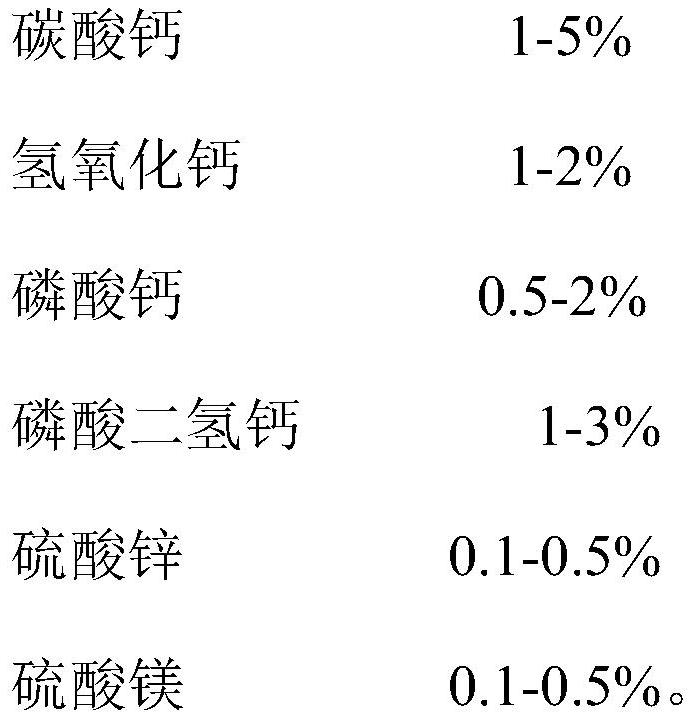

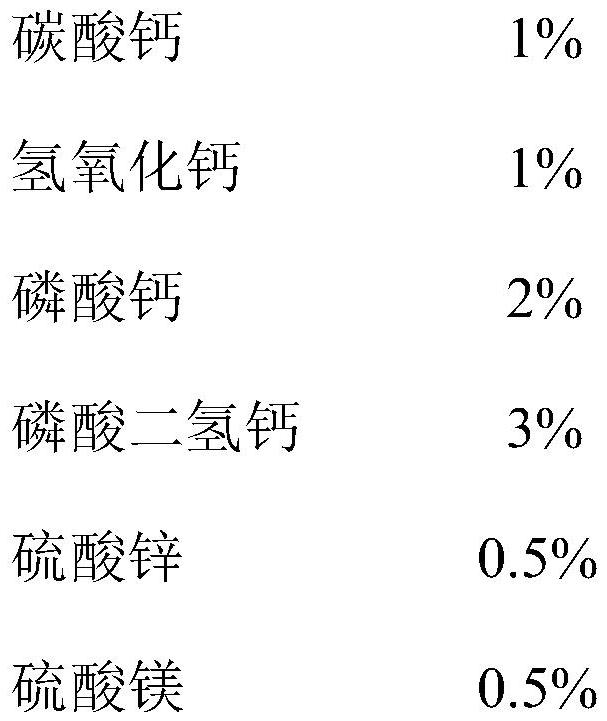

[0037] (3) Soaking in color-protecting solution: the mass ratio of color-protecting solution to wheat seed...

Embodiment 2

[0046] Embodiment two normal temperature pressed product

[0047] (1) Washing: Get 40kg of young barley seedlings within 4-6 months, send them into the washing tank through the conveyor belt, wash them under the disturbance of the air bubbles at the bottom of the washing tank, and then send them to the spray channel for washing again through the conveyor belt; When washing in the pool, the mass ratio of washing water to wheat leaves is 4:1, the water temperature is 20°C, the washing time is 5 minutes, and the water is pure water; when washing in the spray channel, the spray washing time is 5 minutes, the water temperature is 20°C, and the water spray volume is 0.5 kg / kg, water is pure water;

[0048] (2) Cutting: the soaked wheat seedlings are cut into strips or fragments of about 3 cm by a cutting machine, and quickly transferred to the color protection pool for soaking;

[0049] (3) Soaking in color-protecting solution: the mass ratio of color-protecting solution to wheat s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com