A method for preparing ultra-pure iron concentrate by deep processing of commercial grade magnetite concentrate

A technology for ultra-pure iron ore concentrate and magnetite, which is applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problem that the iron grade of the ultra-pure iron ore concentrate is not ideal and the content of acid insoluble matter is too high. Advanced problems, to achieve the effect of small footprint, simple system and good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to describe the present invention, a method for preparing ultra-pure iron concentrate by deep processing of commercial-grade magnetite concentrate of the present invention will be further described in detail in conjunction with the accompanying drawings and examples below.

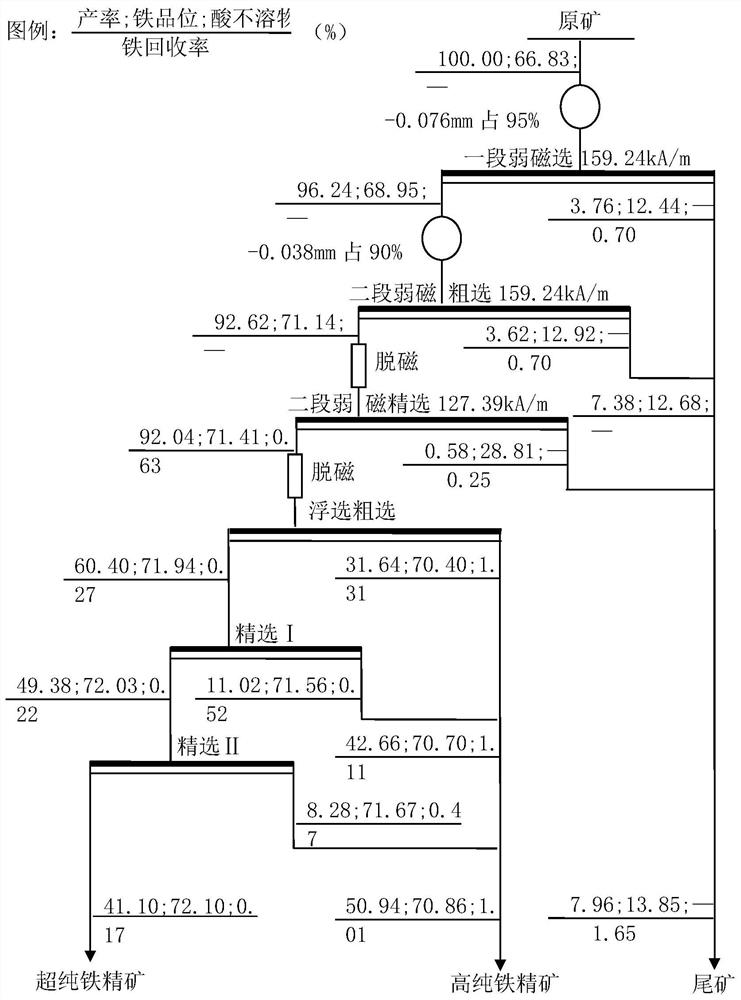

[0025] The TFe grade of a commercial-grade magnetite concentrate in China is 66.83%, and the main impurity is SiO 2 、Al 2 o 3 , CaO, and MgO contents are 6.18%, 0.68%, 0.28%, and 0.22%, respectively, and the contents of other impurity elements are relatively low.

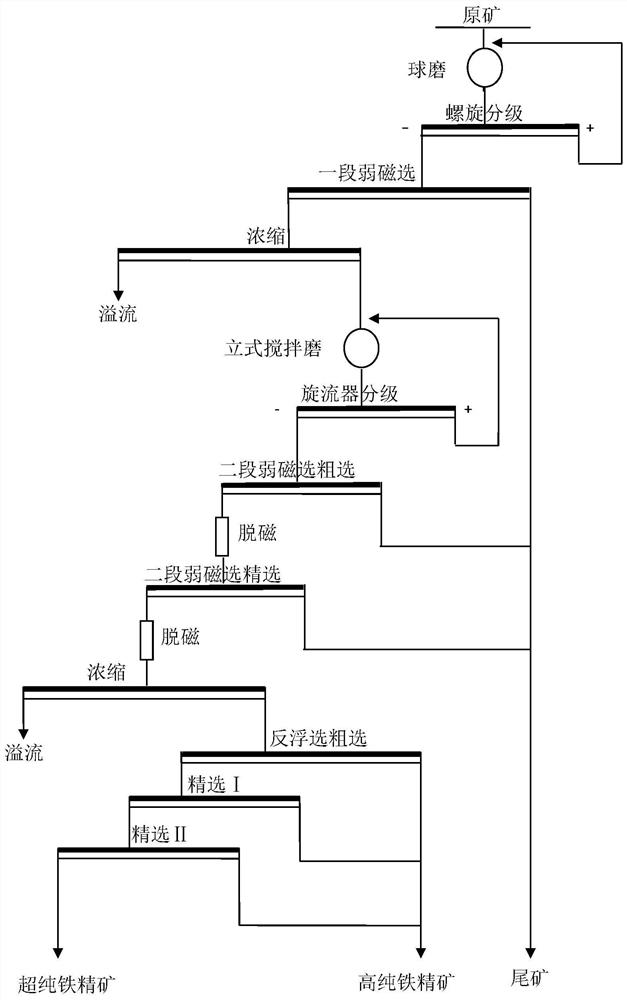

[0026] Depend on figure 1 A kind of commercial grade magnetite concentrate deep processing of the present invention shown is the principle process flow diagram of the method for preparing ultra-pure iron concentrate and combines figure 2 It can be seen that a kind of commercial grade magnetite concentrate deep processing of the present invention prepares the method for ultra-pure iron concentrate to adopt the following proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com