A method of suppressing the clogging of rare earth molten steel pouring nozzle by using pulse current

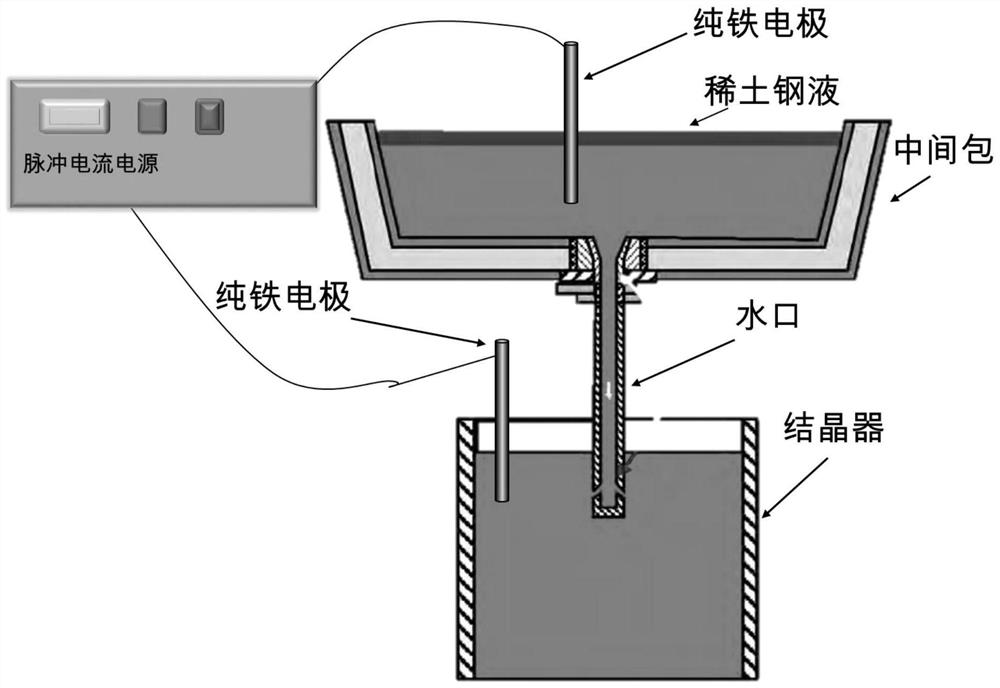

A technology of pulse current and molten steel, which is applied in the direction of manufacturing tools, casting molten material containers, casting equipment, etc., and can solve problems such as nodulation and blockage of nozzles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

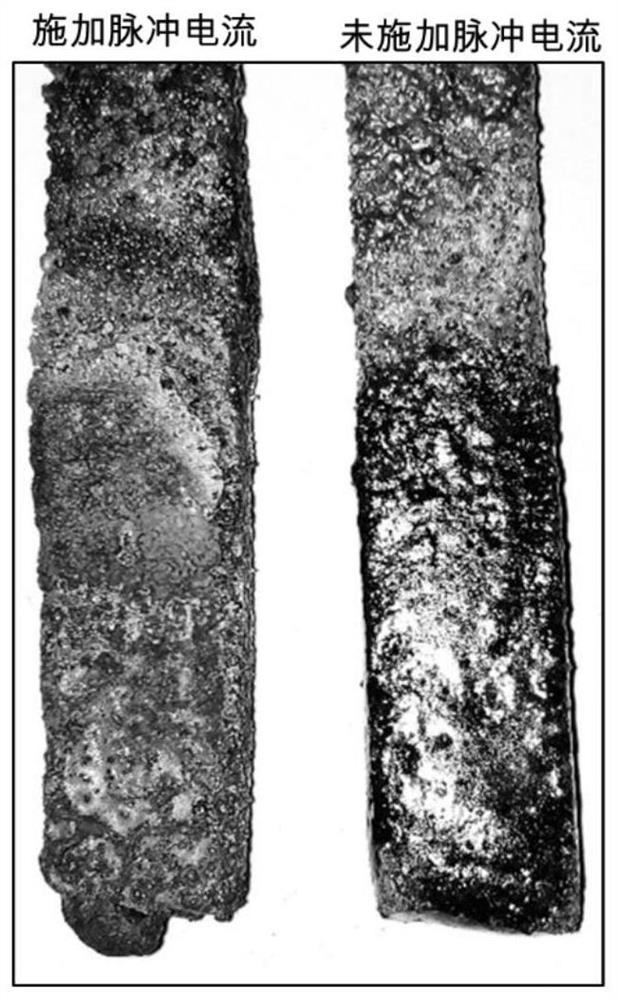

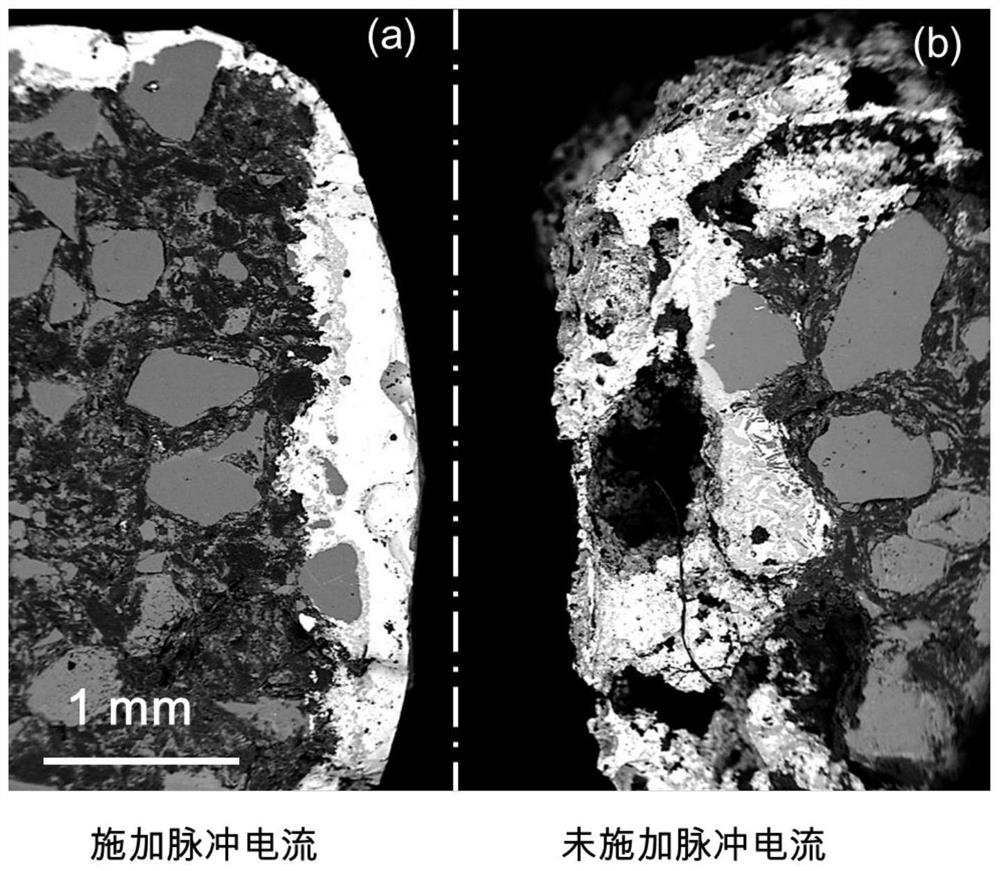

[0052] Step 1: Cut the nozzle for industrial application into a rectangular strip sample of 5×10×300. The sample was polished with 2000-grit sandpaper to make the surface smooth. Under the protection of an inert gas atmosphere, the samples were preheated to above 1000 °C in a resistance furnace.

[0053] The second step: use pure iron as the electrode, the size of the iron rod electrode The iron rods are respectively connected with the positive and negative poles of the electric pulse power supply, and the connecting wires are copper wires with good conductivity.

[0054] Step 3: The bearing steel is polished with sandpaper, and the surface oil is cleaned with acetone. Heat 1kg of bearing steel in a resistance furnace to 1550°C and keep it warm for 60 minutes to make the temperature inside the molten steel uniform. Add lanthanum and cerium rare earth metals into the molten steel, wherein the Ce composition ranges from 60% to 65%, the lanthanum La composition ranges from 30...

Embodiment 2

[0060] Step 1: Cut the nozzle for industrial application into a rectangular strip sample of 5×10×300. The sample was polished with 2000-grit sandpaper to make the surface smooth. Under the protection of an inert gas atmosphere, the samples were preheated to above 1000 °C in a resistance furnace.

[0061] The second step: use pure iron as the electrode, the size of the iron rod electrode The iron rods are respectively connected with the positive and negative poles of the electric pulse power supply, and the connecting wires are copper wires with good conductivity.

[0062] Step 3: The bearing steel is polished with sandpaper, and the surface oil is cleaned with acetone. Heat 1kg of bearing steel in a resistance furnace to 1550°C and keep it warm for 30 minutes to make the temperature inside the molten steel uniform. Lanthanum and cerium rare earth metals are added into molten steel, wherein the composition range of Ce is 60%-65%, the range of lanthanum La composition is 30%...

Embodiment 3

[0068] Step 1: Cut the nozzle for industrial application into a rectangular strip sample of 5×10×300. The sample was polished with 2000-grit sandpaper to make the surface smooth. Under the protection of an inert gas atmosphere, the samples were preheated to above 1000 °C in a resistance furnace.

[0069] The second step: use pure iron as the electrode, the size of the iron rod electrode The iron rods are respectively connected with the positive and negative poles of the electric pulse power supply, and the connecting wires are copper wires with good conductivity.

[0070] Step 3: The bearing steel is polished with sandpaper, and the surface oil is cleaned with acetone. Heat 1kg of bearing steel in a resistance furnace to 1550°C and keep it warm for 10 minutes to make the temperature inside the molten steel uniform. Add lanthanum and cerium rare earth metals into the molten steel, wherein the Ce composition ranges from 60% to 65%, the lanthanum La composition ranges from 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com