PVC floor added with coal gangue powder and preparation method thereof

A technology of coal gangue powder and PVC resin, which is applied in the field of building materials, can solve the problems of affecting the ecological environment, occupying land, polluting the surrounding soil and groundwater, etc., and achieves the effects of long service life, good pressure stability and high toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

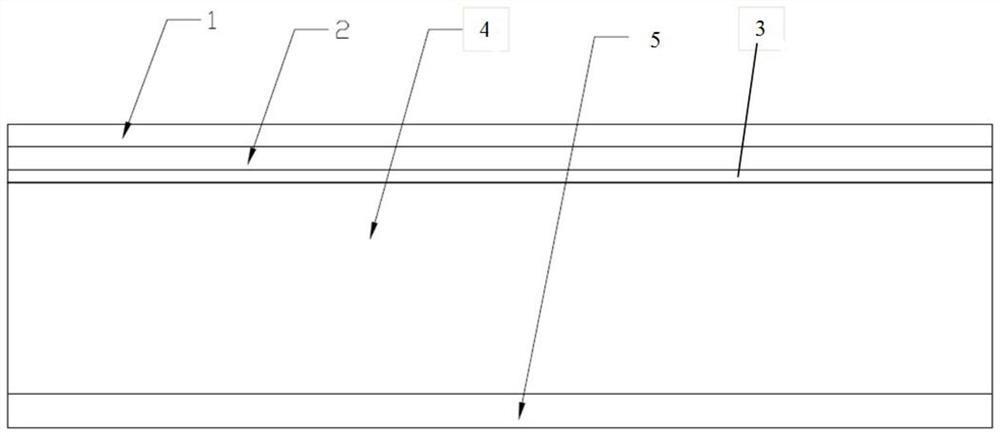

[0040] This embodiment provides a PVC floor, such as figure 1 As shown, the PVC floor includes a UV coating 1 , a wear-resistant layer 2 , a printing layer 3 , a filling layer 4 and a stabilizing layer 5 arranged sequentially from top to bottom. Among them, the thickness of the filling layer is 75% of the total thickness of the PVC floor.

[0041] In this embodiment, the wear-resistant layer is a transparent PVC film, and the printing layer has patterns printed by pigments.

[0042] In this embodiment, the filling layer is composed of the following components by weight: 24 parts of PVC resin, 65 parts of stone powder, 6.5 parts of plasticizer, 3 parts of aluminum hydroxide and 1.5 parts of calcium-zinc stabilizer; wherein, the stone powder is made of coal gangue Composition of powder, marble powder and granite powder, by mass ratio, coal gangue powder:marble powder:granite powder=4.5:2:2; plasticizer is made up of DOTP and DINCH, by mass ratio, DOTP:DINCH=8: 3.

[0043] In ...

Embodiment 2

[0054] This embodiment provides a kind of PVC floor, and its difference with embodiment 1 only lies in:

[0055] (1) The filling layer is made up of the following components by weight: 26 parts of PVC resin, 70 parts of stone powder, 8 parts of plasticizer, 5 parts of aluminum hydroxide and 2 parts of calcium-zinc stabilizer; Wherein, stone powder is made of coal gangue powder, Composition of marble powder and granite powder, by mass ratio, coal gangue powder:marble powder:granite powder=6:3:2.5; plasticizer consists of DOTP and DINCH, by mass ratio, DOTP:DINCH=10:4.

[0056] (2) The stable layer is composed of the following components by weight: 25 parts of PVC resin, 30 parts of coal gangue powder, 25 parts of plasticizer, 3 parts of oxidized polyethylene wax, 1 part of aluminum hydroxide and 1 part of calcium zinc stabilizer ; The plasticizer is composed of DOTP and DINCH, according to the mass ratio, DOTP:DINCH=10:4.

Embodiment 3

[0058] This embodiment provides a kind of PVC floor, and its difference with embodiment 1 only lies in:

[0059] (1) The filling layer is composed of the following components by weight: 20 parts of PVC resin, 60 parts of stone powder, 5 parts of plasticizer, 1 part of aluminum hydroxide and 1 part of calcium-zinc stabilizer; wherein, the stone powder is composed of coal gangue powder, Composition of marble powder and granite powder, in mass ratio, gangue powder:marble powder:granite powder=3:1:1.5; plasticizer is composed of DOTP and DINCH, in mass ratio, DOTP:DINCH=6:2.

[0060] (2) The stabilization layer is composed of the following components by weight: 30 parts of PVC resin, 40 parts of coal gangue powder, 45 parts of plasticizer, 6 parts of oxidized polyethylene wax, 5 parts of aluminum hydroxide and 2 parts of calcium zinc stabilizer ; The plasticizer is composed of DOTP and DINCH, according to the mass ratio, DOTP:DINCH=6:2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com