Thermal self-repairing PNIMMO-based thermoplastic elastomer and preparation method thereof

A thermoplastic elastomer and self-repairing technology, which is applied in the direction of offensive equipment, non-explosive/non-thermal agent components, explosives, etc., can solve the problems of non-energy and cannot meet the application requirements of explosives, and achieve high energy characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

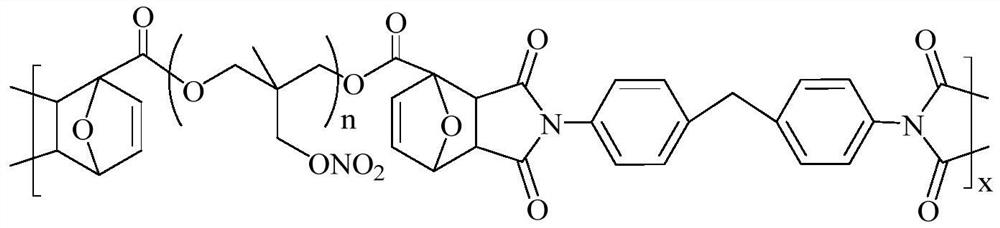

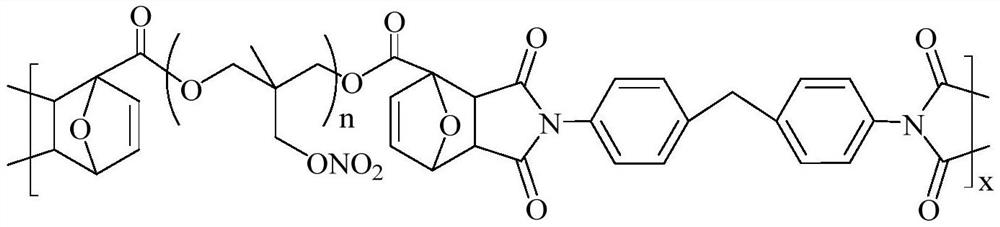

[0030] This embodiment provides a thermal self-healing PNIMMO-based thermoplastic elastomer, which is prepared according to the following method:

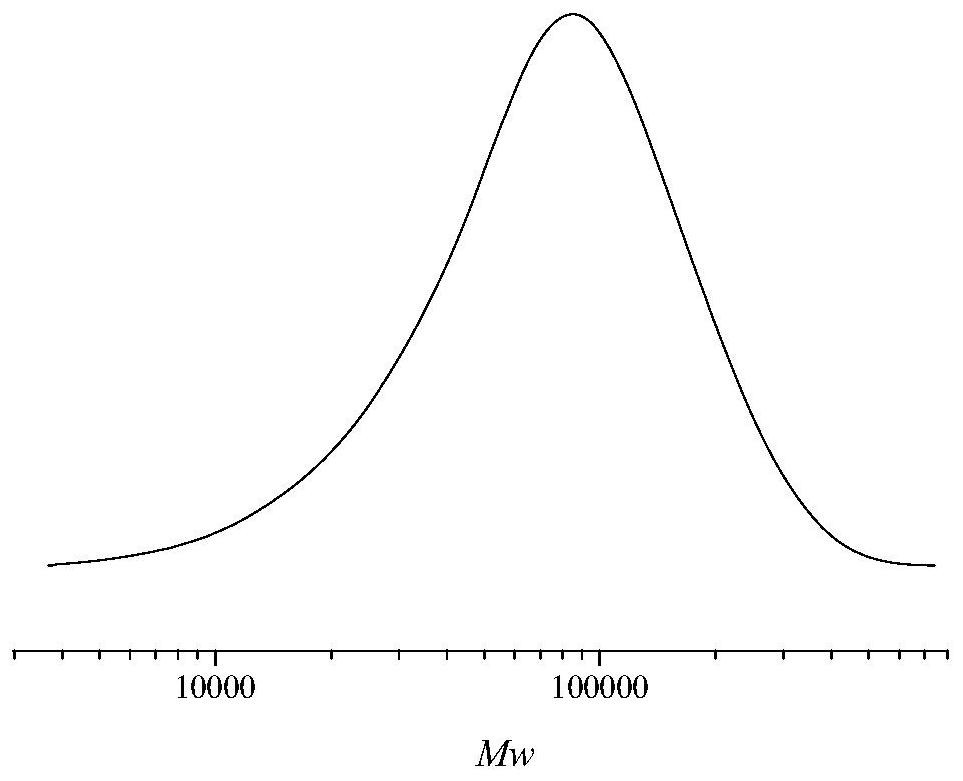

[0031] (1) In a 100mL three-necked round-bottom flask equipped with mechanical stirring, a thermometer and a reflux device, add PNIMMO (8g, 4mmol) with a molecular weight of 2000Da, 12mL of anhydrous tetrahydrofuran, furoyl chloride (1.15g, 8.81mmol) and Fu The acid agent triethylamine (0.81g, 8mmol) forms a mixed solution. Under the protection of a nitrogen atmosphere, the mixed solution is stirred and reacted at room temperature for 30h; Modified PNIMMO;

[0032] (2) 6g of the furan-terminated PNIMMO synthesized above was added to a 100mL three-necked round-bottomed flask equipped with mechanical stirring, a thermometer and a reflux device containing 10mL of dichloroethane solvent, and stirred and mixed uniformly to form a mixed solution; Under the protection of the atmosphere, add 4,4'-bismaleimido diphenylmethane chain extende...

Embodiment 2

[0037] This embodiment provides a thermal self-healing PNIMMO-based thermoplastic elastomer, which is prepared according to the following method:

[0038] (1) In a 100mL three-necked round-bottom flask equipped with mechanical stirring, a thermometer and a reflux device, sequentially add PNIMMO (16g, 4mmol) with a molecular weight of 4000Da, 18mL of anhydrous tetrahydrofuran, furoyl chloride (1.25g, 9.58mmol) and Fu The acid agent triethylamine (0.89g, 8.79mmol) forms a mixed solution. Under the protection of a nitrogen atmosphere, the mixed solution is stirred and reacted at room temperature for 24 hours; Furan-modified PNIMMO;

[0039] (2) 12g of the furan-terminated PNIMMO synthesized above was added to a 100mL three-neck round-bottomed bottle equipped with mechanical stirring, a thermometer and a reflux device containing 16mL of dichloroethane solvent, stirred and mixed to form a mixed solution; Under the protection of the atmosphere, add 4,4'-bismaleimido diphenylmethane...

Embodiment 3

[0041] This embodiment provides a thermal self-healing PNIMMO-based thermoplastic elastomer, which is prepared according to the following method:

[0042] (1) In a 100mL three-neck round-bottom flask equipped with mechanical stirring, a thermometer and a reflux device, add PNIMMO (24g, 4mmol) with a molecular weight of 6000Da, 26mL of anhydrous tetrahydrofuran, furoyl chloride (1.46g, 11.2mmol) and Fu The acid agent triethylamine (0.97g, 9.58mmol) forms a mixed solution. Under the protection of nitrogen atmosphere, the mixed solution is stirred and reacted at room temperature for 20h; after the reaction time is up, the reaction solution is concentrated, washed, and vacuum-dried at 40°C to obtain terminal Furan-modified PNIMMO;

[0043] (2) 18g of the furan-terminated PNIMMO synthesized above was added to a 100mL three-necked round-bottomed bottle equipped with mechanical stirring, a thermometer and a reflux device containing 28mL of dichloroethane solvent, stirred and mixed un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com