Preparation and application methods of porous boron nitride nanofiber/polyvinyl alcohol composite hydrogel

A composite hydrogel and nanofiber technology, applied in nitrogen compounds, chemical instruments and methods, nanotechnology, etc., can solve problems such as field limitations, complex methods, and hydrogels do not have self-healing properties, and achieve enhanced mechanical properties. , the preparation process is simple and the cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

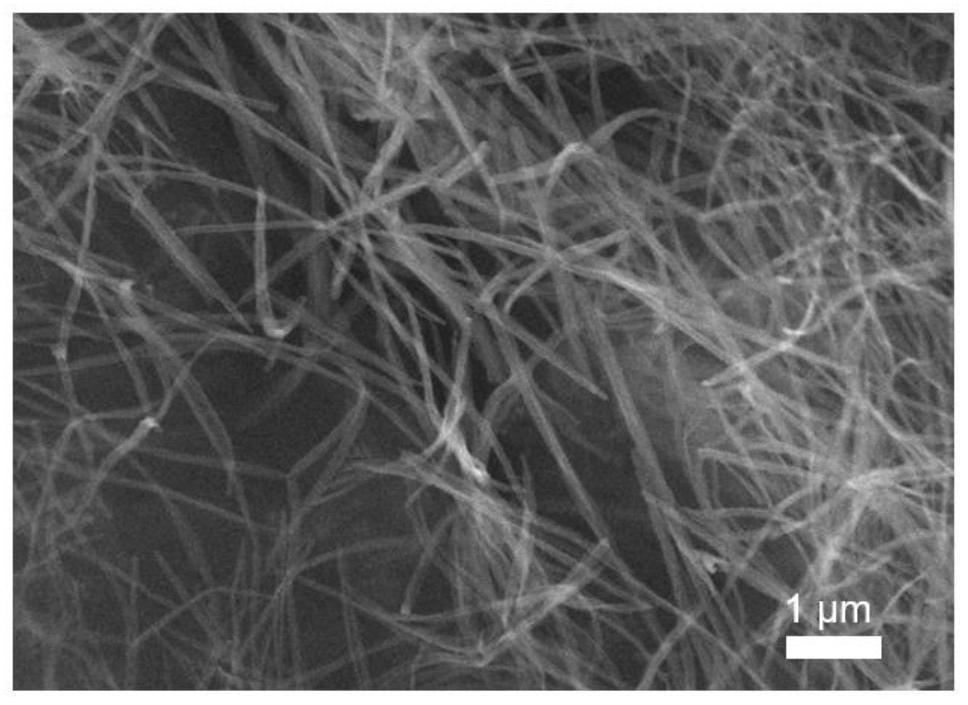

[0034] Select melamine and boric acid as raw materials, dissolve them in 1000 ml of deionized water, the concentration of which is 0.0126 g of melamine and 0.018 g of boric acid per ml of water, heat them at 90°C to fully dissolve them and keep them at 80°C for 6 hours, take them out and cool them naturally to room temperature, pump Filter the white solid; redissolve the white solid in deionized water at a concentration of 0.008 g of white solid per milliliter of water, keep it warm at 90°C for 3 hours, then quickly freeze the hot solution with liquid nitrogen to make the solution completely turn into a white solid, and Dry in a vacuum freeze dryer (temperature -50°C, 20Pa) for 72 hours to obtain white flocs; finally, heat treatment in a tube furnace at 1050°C for 4 hours under a nitrogen atmosphere with a heating rate of 5°C / min and a gas flow rate of 100mL / min to obtain porous BNNFs.

Embodiment 2-5

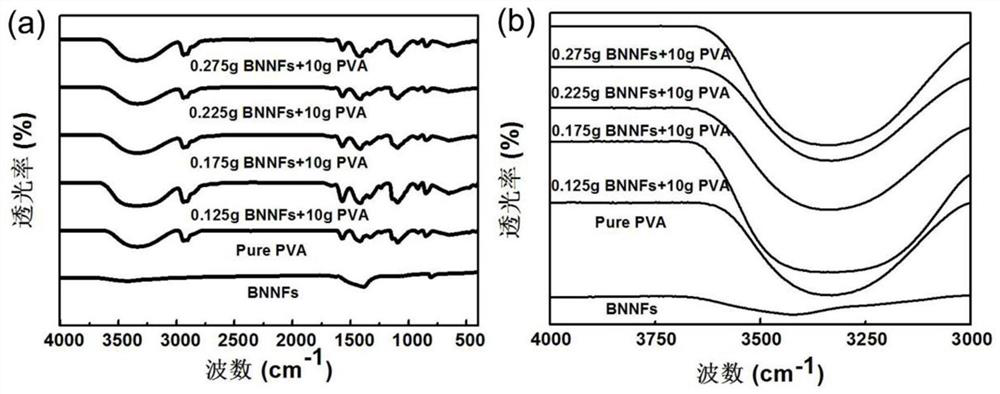

[0036] Weigh the prepared porous BNNFs 0.125, 0.175, 0.225, 0.275g, respectively dispersed in 100mL deionized water, magnetically stirred for 180min, and then 10g white flocculent PVA (molecular weight: 77000). Add to the above dispersion liquid respectively, heat and stir in a water bath for 2 hours, then turn off the stirring and keep warm for 1 hour (both heating and heat preservation temperatures are 95°C), then pour the prepared high-temperature sol into a mold and cool to room temperature, Hydrogels with high self-healing efficiency were obtained.

Embodiment 6-8

[0038] In order to further enhance the mechanical strength of the prepared porous BNNFs / PVA composite hydrogel. The prepared hydrogels (0.125, 0.175, 0.225 g of BNNFs added) were frozen at -25 °C for 1 h, and then naturally thawed to room temperature at room temperature (25 °C), resulting in better flexibility and higher mechanical strength. Hydrogel: After a short period of freeze-thaw treatment, the number of reversible hydrogen bonds in the hydrogel decreases, resulting in a decrease in self-healing efficiency, and the crystallinity of the PVA molecular chain increases, resulting in an increase in mechanical strength. It is found that the two are inversely proportional to each other. , indicating that the self-healing properties of hydrogels will be reduced while improving the mechanical properties of the hydrogel.

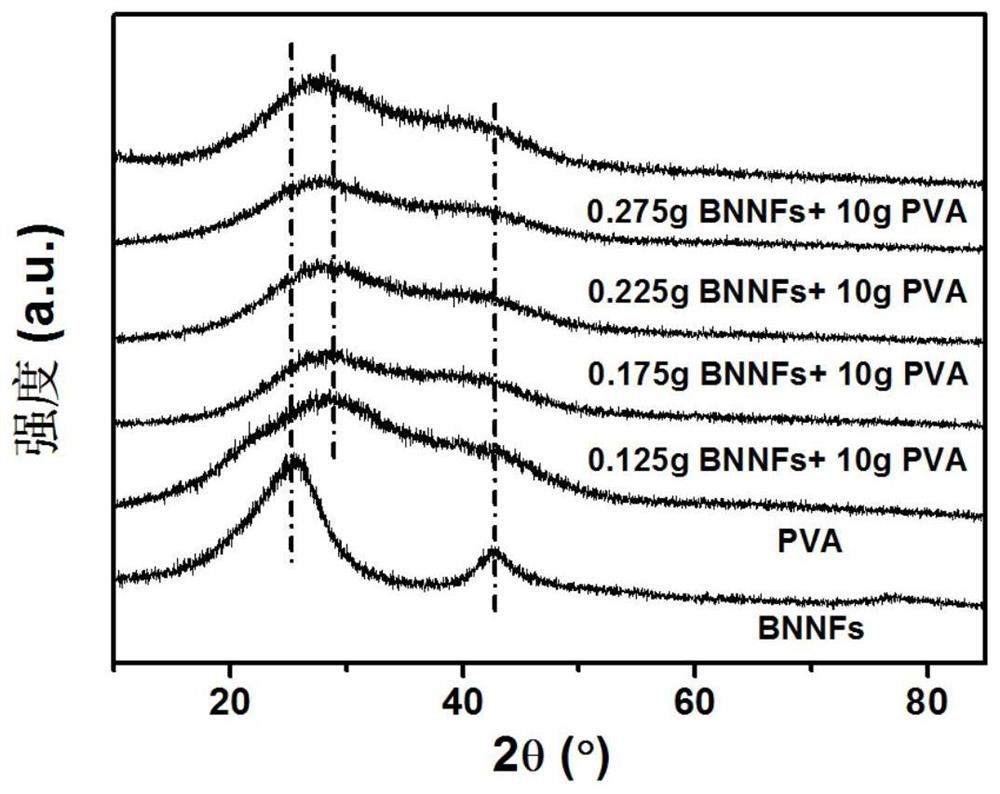

[0039] attached figure 1 The XRD collection of patterns in shows that without adding BN, the diffraction peaks of 10wt% (PVA / deionized water) PVA aqueous solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com