Polyvinyl alcohol-based strippable film detergent, preparation method and use method thereof

A technology based on polyvinyl alcohol and polyvinyl alcohol, which is applied to the field of radioactive decontamination of the surface of nuclear facilities by polymer chemical decontamination agents, which can solve the problems of long time-consuming film formation, poor mechanical properties, and difficult storage, and achieve a green price Environmental protection, good film-forming property and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

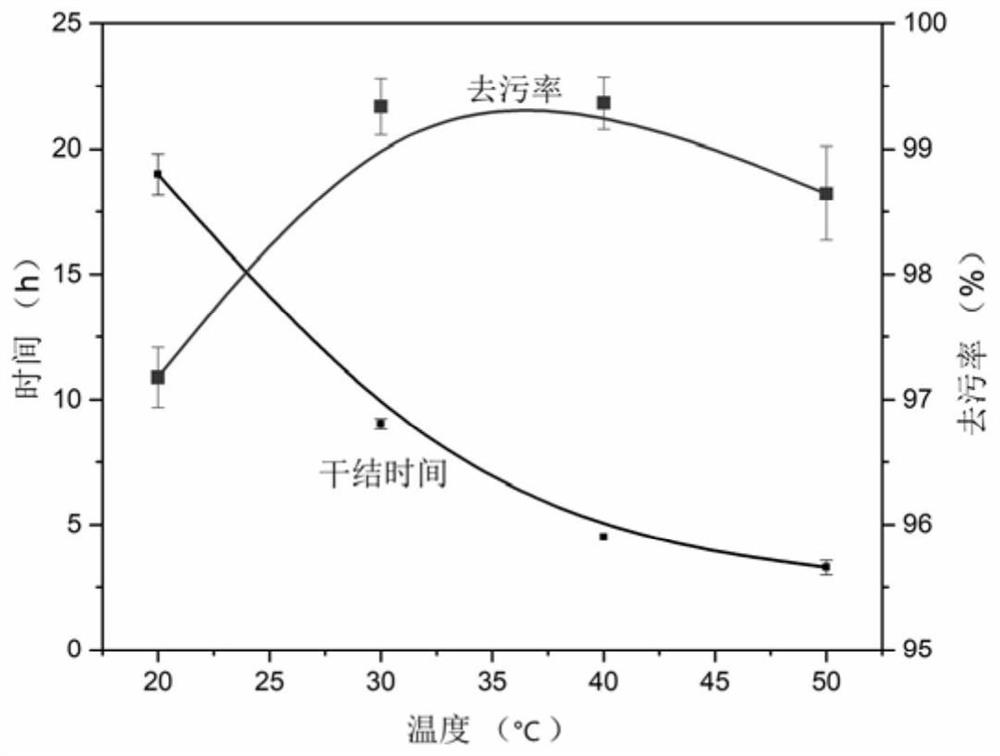

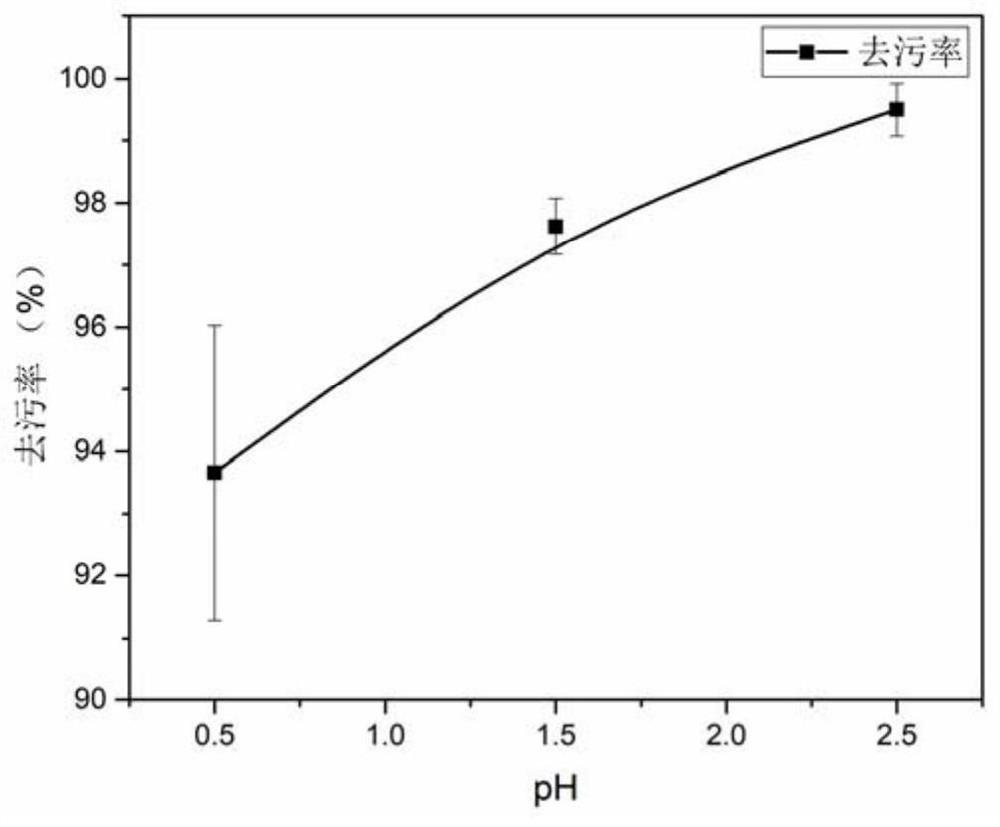

[0041] A preparation method of a polyvinyl alcohol-based peelable film detergent, mixing the components of the polyvinyl alcohol-based peelable film detergent for at least 1 hour to prepare a polyvinyl alcohol-based peelable film detergent.

[0042] In one embodiment, the preparation method of a polyvinyl alcohol-based peelable film detergent: prepare a 10-20 wt% polyvinyl alcohol solution with water, heat to 95-100°C to dissolve for at least 24 hours, and then cool down to 70-85 Add gelling agent after ℃, mix for at least 10 minutes, then add surfactant, adhesive, thickener, reinforcing agent, complex chelating agent, dispersant, plasticizer, lubricant and preservative in sequence, continue to Mix the reaction for at least 1h, that is. The detergent prepared by this preparation method is not easy to delaminate and has a longer storage time.

[0043] The present invention also provides methods of using polyvinyl alcohol-based strippable stain release agents.

[0044] The use...

Embodiment 1

[0060] (1) Preparation of oxidized starch: take a clean beaker, add soluble starch and water, the mass ratio of soluble starch and water is 1:3, mix and stir evenly, add a certain amount of H 2 o 2 (30% concentration) and FeCl 2 , and continued to stir and react for 30 minutes under the condition of 50 ° C water bath, let it stand to room temperature, then performed suction filtration operation, and washed the filter cake with absolute ethanol and deionized water for more than 3 times to remove soluble impurities, and finally put the product in Dry in an oven at 60°C to obtain oxidized starch. The prepared oxidized starch was used as adhesive.

[0061] (2) Preparation of peelable membrane detergent: take a clean three-necked round-bottomed flask, install a condenser, place it in a water bath, then add 15g of PVA and 135g of water to the round-bottomed flask, and heat it at 95-98°C Dissolve at low temperature for 24 hours, then lower the temperature of the water bath to 75°C...

Embodiment 2

[0065] (1) Get the oxidized starch that embodiment 1 makes, as adhesive.

[0066] (2) Preparation of peelable membrane detergent: take a clean three-neck round bottom flask, install a condenser, place it in a water bath, then add 30g of PVA and 135g of water to the round bottom flask, and heat it at 95-98°C Dissolve at low temperature for 24 hours, then lower the water bath temperature to 75°C, add 1g agar, mix and stir for 10 minutes, then add 0.1g sodium dodecylsulfonate, 1g oxidized starch, 0.1g hydroxymethyl cellulose, 1g white carbon black , 0.1g complex chelating agent (made by mixing EDTA-2Na and sodium tripolyphosphate at a mass ratio of 1:3), 0.5g polyethylene glycol-1000, 0.8g propylene glycol, 0.5g Span-20, 0.8g sodium benzoate , after the addition was completed, the stirring reaction was continued for 1 h, and the temperature was naturally lowered to obtain the detergent.

[0067] The observed detergent: placed at room temperature, after standing for 20 days, no d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com