Polyurethane waterproof coating material and preparation method thereof

A waterproof coating and water-based polyurethane technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of limited organic volatile emissions, harsh construction, high VOC, etc., and achieve superior waterproofness, easy construction, and low VOC Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

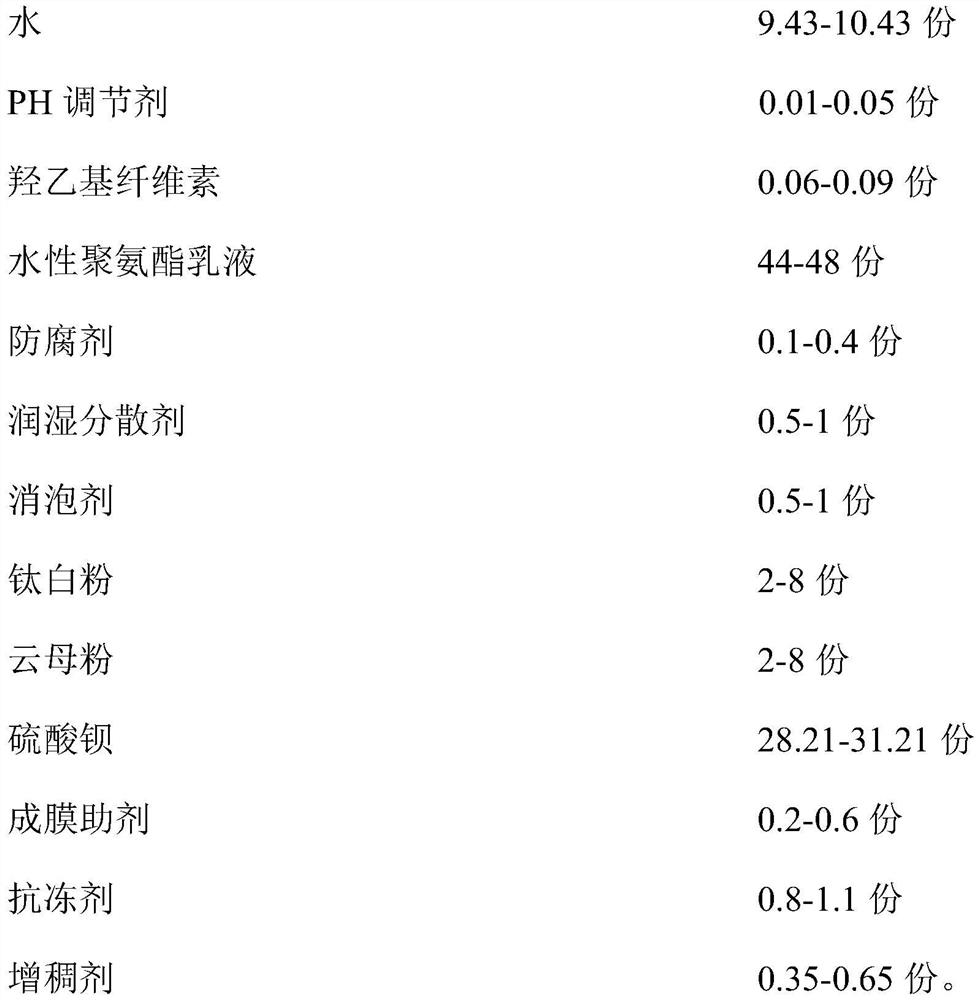

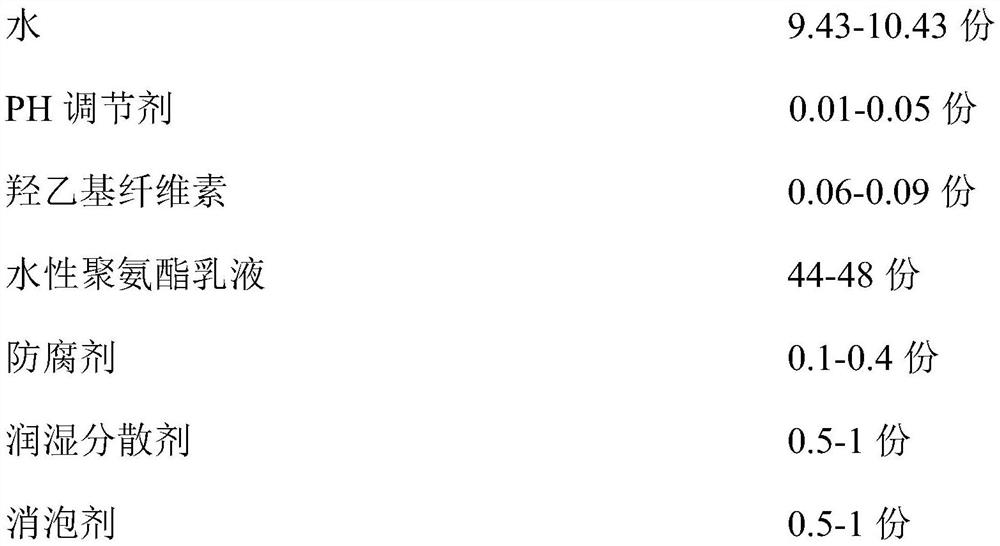

[0046]

[0047] Craftsmanship:

[0048] (1) Add water into the dispersing tank, add pH regulator and hydroxyethyl cellulose in sequence, control the rotation speed within the range of 300r / min, and continue to disperse for 10min;

[0049] (2) Slowly add water-based polyurethane emulsion, preservative, wetting and dispersing agent, defoamer, adjust the speed to 400r / min, and continue to disperse for 10 minutes;

[0050] (3) Increase the rotational speed to 900r / min, add titanium dioxide in batches, and continue to disperse for 20 minutes;

[0051] (4) Reduce the rotational speed to 800r / min, slowly add mica powder and barium sulfate in turn, and continue to disperse for 25 minutes;

[0052] (5) Add film-forming aids, antifreeze agents, and thickeners at a speed of 500r / min, and continue to disperse for 15 minutes until the liquid is a uniform, white mixture without particles.

Embodiment 2

[0054] A kind of waterborne polyurethane waterproof coating embodiment 2, its concrete raw material and weight proportion are as follows:

[0055]

[0056] Craftsmanship:

[0057] (1) Add water into the dispersion tank, add pH regulator and hydroxyethyl cellulose in sequence, control the rotation speed within the range of 400r / min, and continue to disperse for 10min;

[0058] (2) Slowly add water-based polyurethane emulsion, preservative, wetting and dispersing agent, defoamer, adjust the speed to 500r / min, and continue to disperse for 10 minutes;

[0059] (3) Increase the rotational speed to 950r / min, add titanium dioxide in batches, and continue to disperse for 15 minutes;

[0060] (4) Reduce the rotation speed to 750r / min, slowly add mica powder and barium sulfate in turn, and continue to disperse for 20 minutes;

[0061] (5) Add film-forming aids, antifreeze agents, and thickeners at a speed of 600r / min, and continue to disperse for 15 minutes until the liquid is a un...

Embodiment 3

[0063] A kind of water-based polyurethane waterproof coating invention embodiment 3, its concrete raw material and weight ratio are as follows:

[0064]

[0065] Craftsmanship:

[0066] First add water into the dispersion tank, then add the pH regulator and hydroxyethyl cellulose, and then disperse for 10 minutes at a rotation speed of 300r / min;

[0067] Then add water-based polyurethane emulsion, preservative, wetting and dispersing agent and defoamer, adjust the speed to 400r / min and disperse at this speed for 10min;

[0068] Then adjust the rotation speed to 900r / min, then add titanium dioxide in 2 times, and then continue to disperse for 20 minutes;

[0069] Then reduce the rotation speed to 800r / min, slowly add mica powder and barium sulfate in turn, and then continue to disperse for 25 minutes;

[0070] Finally, add film-forming aids, antifreeze agents and thickeners at a speed of 500r / min, and continue to disperse for 30 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com