Heating anode integrated material for thermal battery and preparation method thereof

A thermal battery, positive electrode technology, applied in battery cooling/heating, primary battery use/maintenance, battery electrodes, etc., can solve the problems of large proportion of heating powder and positive electrode material, short working time, low specific energy of thermal battery, etc. Achieve the effects of good electrical conductivity, low equipment cost and gentle heat release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

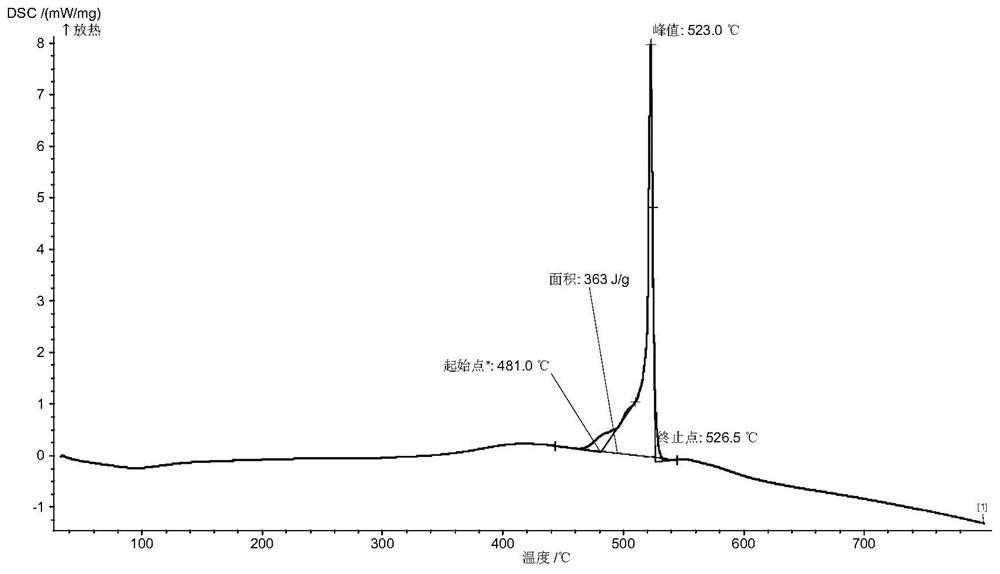

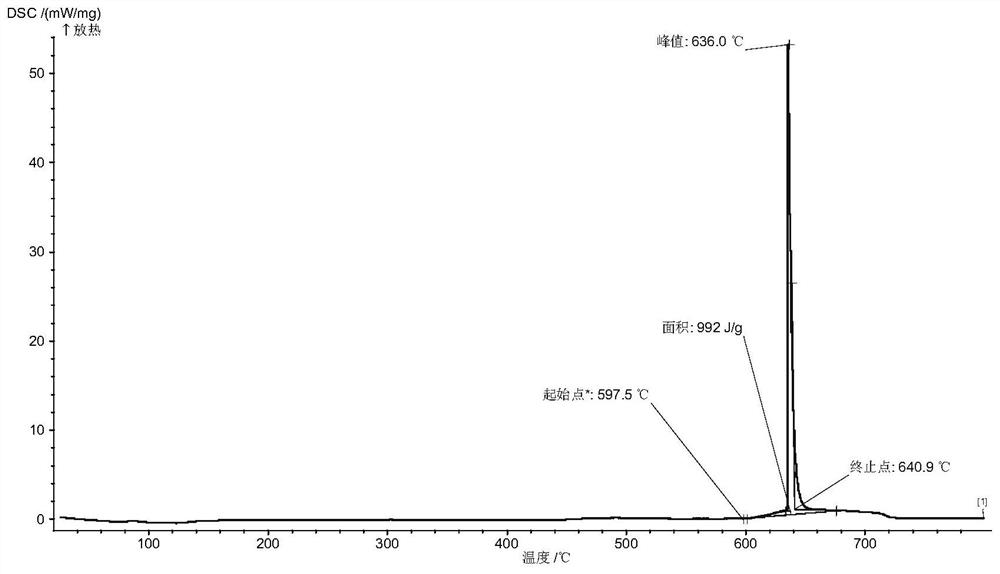

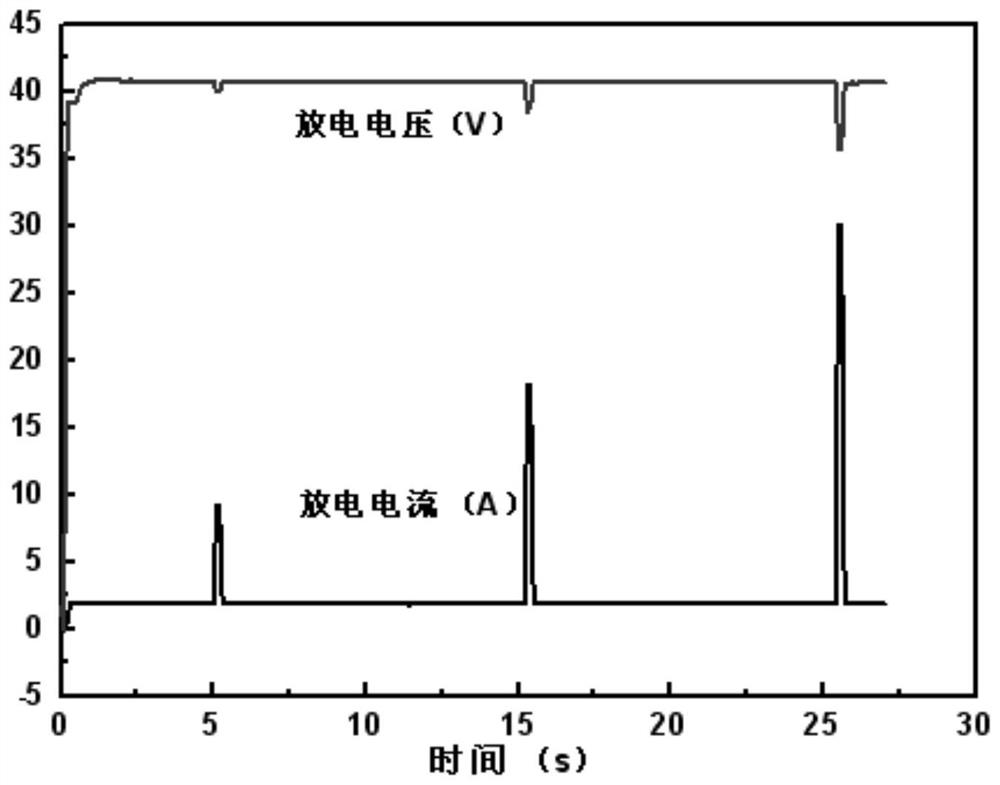

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing a heating positive electrode integrated material for a thermal battery, comprising the steps of:

[0030] 1) First put CuO, Al, LiCl-KCl, and lithium oxide raw materials into an inert drying oven at a temperature of 110°C to dry for later use;

[0031] 2) Weigh 165gCuO and 6gLi respectively 2 O, 20gLiCl-KCl, the CuO, Li 2 O and LiCl-KCl were mixed evenly in a high-speed powder mixer, transferred to an inert drying oven at a temperature of 450°C for 8 hours, the sample was taken out to cool, mechanically pulverized, and sieved with 80 meshes, the prepared powder was a heating positive electrode integrated material Precursor;

[0032] 3) Finally, uniformly mix the precursor of the heating positive electrode integrated material prepared in 2) and 15 g of aluminum powder to obtain the heating positive electrode integrated material for the thermal battery.

Embodiment 2

[0034] A method for preparing a heating positive electrode integrated material for a thermal battery, comprising the steps of:

[0035] 1) First put CuO, Al, LiCl-KCl, and lithium oxide raw materials into a vacuum drying oven at a temperature of 110°C to dry for later use;

[0036] 2) Weigh 160gCuO and 6gLi respectively 2 O, 20gLiCl-KCl, the CuO, Li 2 O and LiCl-KCl were mixed evenly in a high-speed powder mixer, transferred to a vacuum drying oven at 450°C for 8 hours, the samples were taken out to cool, mechanically pulverized, and sieved with 80 meshes, the prepared powder was a heating positive electrode integrated material Precursor;

[0037]3) Finally, mix the precursor of the heating positive electrode integrated material prepared in 2) and 20 g of aluminum powder evenly.

Embodiment 3

[0039] A method for preparing a heating positive electrode integrated material for a thermal battery, comprising the steps of:

[0040] 1) First put the MoO 3 , Al, LiCl-KCl, and lithium oxide raw materials are placed in a vacuum drying oven at a temperature of 110°C for drying for later use;

[0041] 2) Weigh 160g MoO respectively 3 、6gLi 2 O, 20gLiCl-KCl, the CuO, Li 2 O and LiCl-KCl were mixed evenly in a high-speed powder mixer, transferred to a vacuum drying oven at a temperature of 450°C for 8 hours, the samples were taken out to cool, mechanically pulverized, and sieved with 80 meshes to prepare the precursor of the heating positive electrode integrated material;

[0042] 3) Finally, mix the heated cathode integrated material precursor prepared in 2) and 20g of aluminum powder evenly

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com