Positive pole piece, manufacturing method thereof and secondary battery

A technology for positive pole pieces and manufacturing methods, which is applied to battery electrodes, electrode manufacturing, electrode collector coatings, etc., can solve problems affecting the performance of positive pole pieces, and achieve improved performance, reduced corrosion, and reduced contact area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

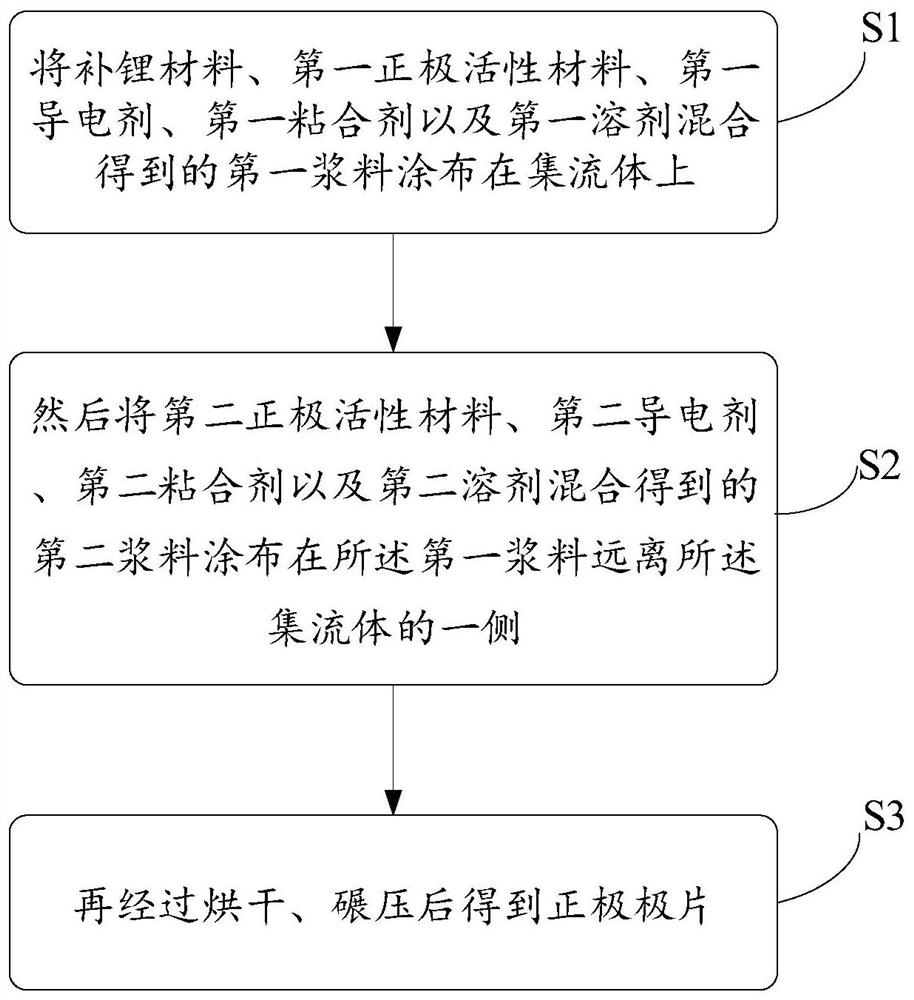

Method used

Image

Examples

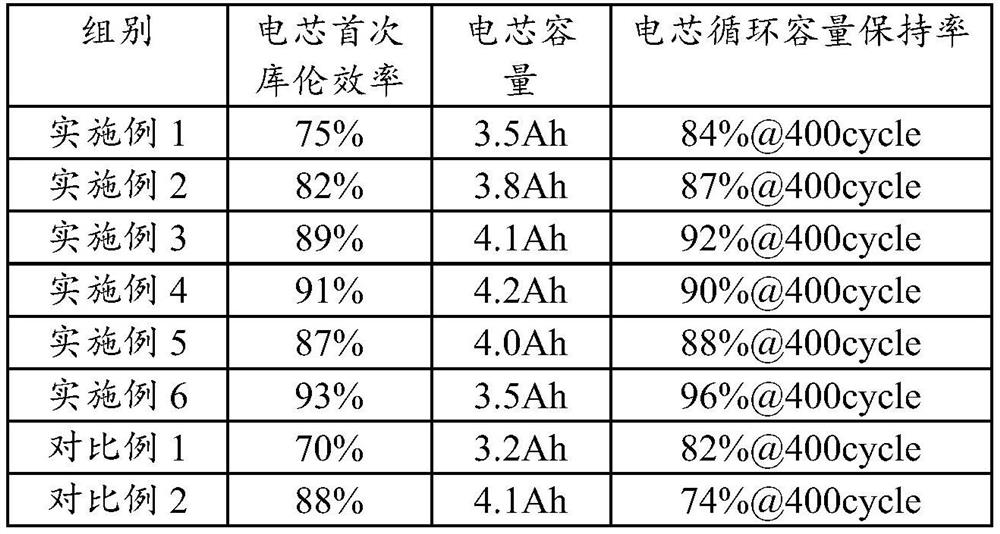

Embodiment 1

[0090] 1wt% Li 2 NiO 2 , and 97.5wt% nickel cobalt lithium manganese oxide LiNi 0.8 mn 0.1 co 0.1 o 2 The particles, 0.5wt% of sp, and 1wt% of pvdf are added to the solvent and stirred to obtain a mixed slurry, forming a uniform and stable first slurry. 97wt% nickel cobalt lithium manganese oxide LiMn 0.8 Ni 0.1 co 0.1 o 2 The particles, 2wt% of sp, and 1wt% of pvdf are added to the solvent and stirred to obtain a mixed slurry, forming a uniform and stable second slurry. The first slurry and the second slurry are coated on the surface of the aluminum foil in layers at the same time, so that the first slurry is coated on the bottom layer directly in contact with the current collector, and the second slurry is on the surface layer away from the current collector. The coating width of the first slurry and the second slurry is 60 mm, and the coating thickness ratio is 30%:70%. Afterwards, the pole pieces were dried and rolled, the drying temperature was 110°C, the rollin...

Embodiment 2

[0092] 30wt% Li 2 NiO 2 , and 66.2wt% nickel-cobalt lithium manganese oxide LiNi 0.8 mn 0.1 co 0.1 o 2 The particles, 2wt% of sp, and 1.8wt% of pvdf were added to the solvent and stirred to obtain a mixed slurry, forming a uniform and stable first slurry. 97wt% nickel cobalt lithium manganese oxide LiMn 0.8 Ni 0.1 co 0.1 o 2 The particles, 2wt% of sp, and 1wt% of pvdf are added to the solvent and stirred to obtain a mixed slurry, forming a uniform and stable second slurry. The first slurry and the second slurry are coated on the surface of the aluminum foil in layers at the same time, so that the first slurry is coated on the bottom layer directly in contact with the current collector, and the second slurry is on the surface layer away from the current collector. The coating width of the first slurry and the second slurry is 60 mm, and the coating thickness ratio is 30%:70%. Afterwards, the pole pieces were dried and rolled, the drying temperature was 110°C, the roll...

Embodiment 3

[0094] 50wt% Li 2 NiO 2 , and 76.2wt% nickel-cobalt lithium manganese oxide LiNi 0.8 mn 0.1 co 0.1 o 2 The particles, 2wt% of sp, and 1.8wt% of pvdf were added to the solvent and stirred to obtain a mixed slurry, forming a uniform and stable first slurry. 97wt% nickel cobalt lithium manganese oxide LiMn 0.8 Ni 0.1 co 0.1 o 2 The particles, 2wt% of sp, and 1wt% of pvdf are added to the solvent and stirred to obtain a mixed slurry, forming a uniform and stable second slurry. The first slurry and the second slurry are coated on the surface of the aluminum foil in layers at the same time, so that the first slurry is coated on the bottom layer directly in contact with the current collector, and the second slurry is on the surface layer away from the current collector. The coating width of the first slurry and the second slurry is 60mm, and the coating thickness ratio of the first slurry and the second slurry is 30%:70%, and then the pole piece is dried, rolled, and dried. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com