Connection structure of membrane electrode and shell

A technology of thin film electrode and connection structure, applied in the field of connection structure between thin film electrode and shell, can solve the problems of increasing the size of thin film electrode and external structure, and achieve the effect of not easy to loosen, avoid size limitation, and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

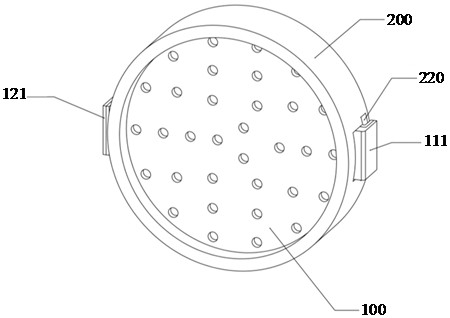

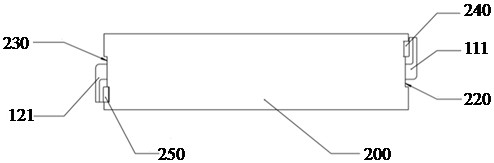

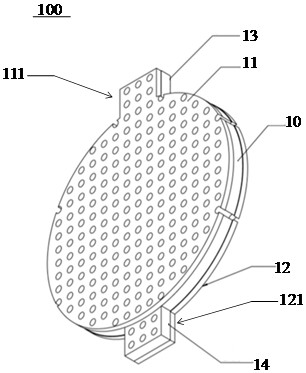

[0039] combine Figure 1 to Figure 5 As shown, the connection structure between the thin film electrode and the case of this embodiment includes a thin film electrode unit 100 and a case 200 . The membrane electrode unit 100 includes a porous membrane 10 , a first electrode 11 and a second electrode 12 , and the first electrode 11 and the second electrode 12 are attached to two sides of the porous membrane 10 . Wherein, the porous film 10 of this embodiment is a flexible porous film, the first electrode 11 only covers the central circular part of the porous film 10 and the first protruding end 13 , and the second protruding end 14 is not covered by the first electrode 11 . The second electrode 12 only covers the central circular part and the second extension 14 of the porous film 10, and the first extension 13 has no second electrode 12 to cover, so that the first extension 13 and the first extension 13 covering its surface The electrode 11 forms a first electrical connection...

Embodiment approach 2

[0052] combine Figure 6 to Figure 9 As shown, the porous film 10 of this embodiment is a rigid porous film, and the porous film 10 has a circular structure without the setting of the protruding end. The first electrode 11 is modified on one side of the porous film 10 by sputtering, atomic layer deposition, chemical vapor deposition, electroless deposition, etc., and during the modification process, the same side is covered by a mask for forming the second electrode. A portion of linker unit 121 forms an optional modification. In the same way, the second electrode 12 is selectively modified on the other side of the porous film 10, and during the modification process, the part used to form the first electrical connection unit 111 on the same side is covered by a mask, wherein the first The first electrical connection unit 111 and the second electrical connection unit 121 are arranged at a certain angle to avoid a short circuit during the electrical connection with the casing. ...

Embodiment approach 3

[0059] combine Figure 10 and Figure 11As shown, the porous film 10 of this embodiment is also a rigid porous film. The inner wall surface on the casing 200 is also provided with a first sample adding groove 270 and a second sample adding groove 280, and the first sample adding groove 270 and the second sample adding groove 280 are respectively arranged on both sides of the installation groove 210, and are respectively connected with The first electrical connection unit 111 and the second electrical connection unit 121 are disposed opposite to each other, a first exhaust hole 271 is provided on the first sample adding tank 270 , and a second exhaust hole is provided on the second sample adding tank 280 . Wherein, the exhaust hole and the sample adding groove can be made on the casing 200 by machining, injection molding, etching, 3D printing and other methods. In this embodiment, the casing 200 also includes a first casing and a second casing connected in a detachable manner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com