MXene/titanium dioxide nanotube composite material photocatalyst and preparation method thereof

A technology of titanium dioxide and composite materials, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of adverse effects on photocatalytic activity, small specific surface area, and impact on Schottky barriers, etc. Achieve the effect of good product appearance, high photocatalytic activity and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

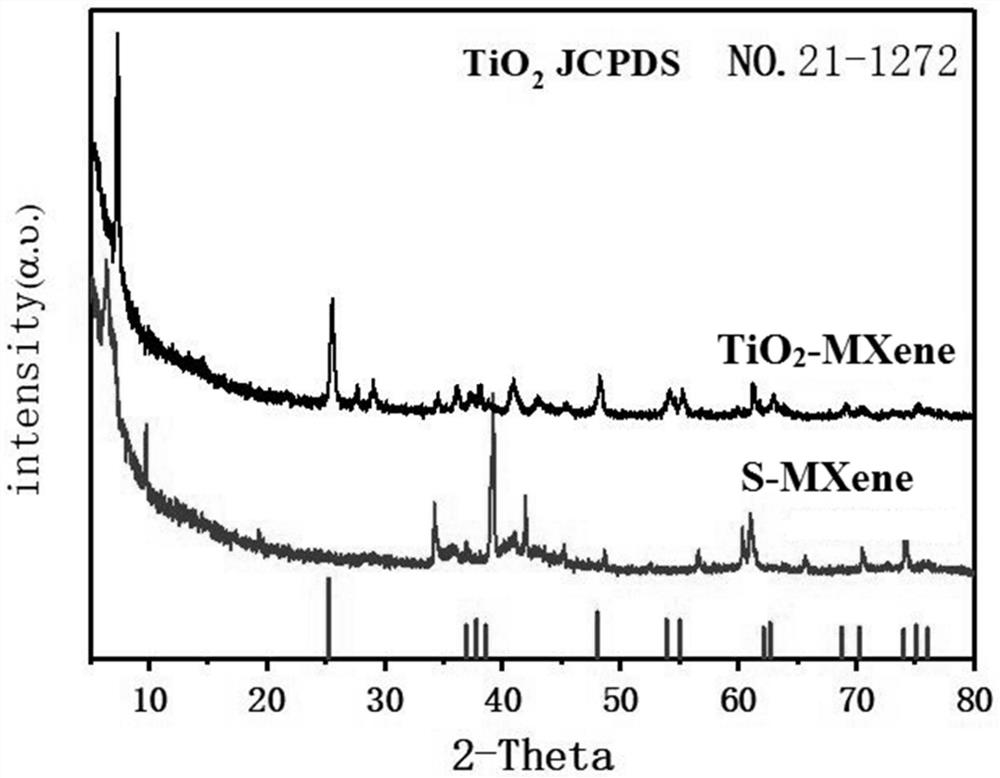

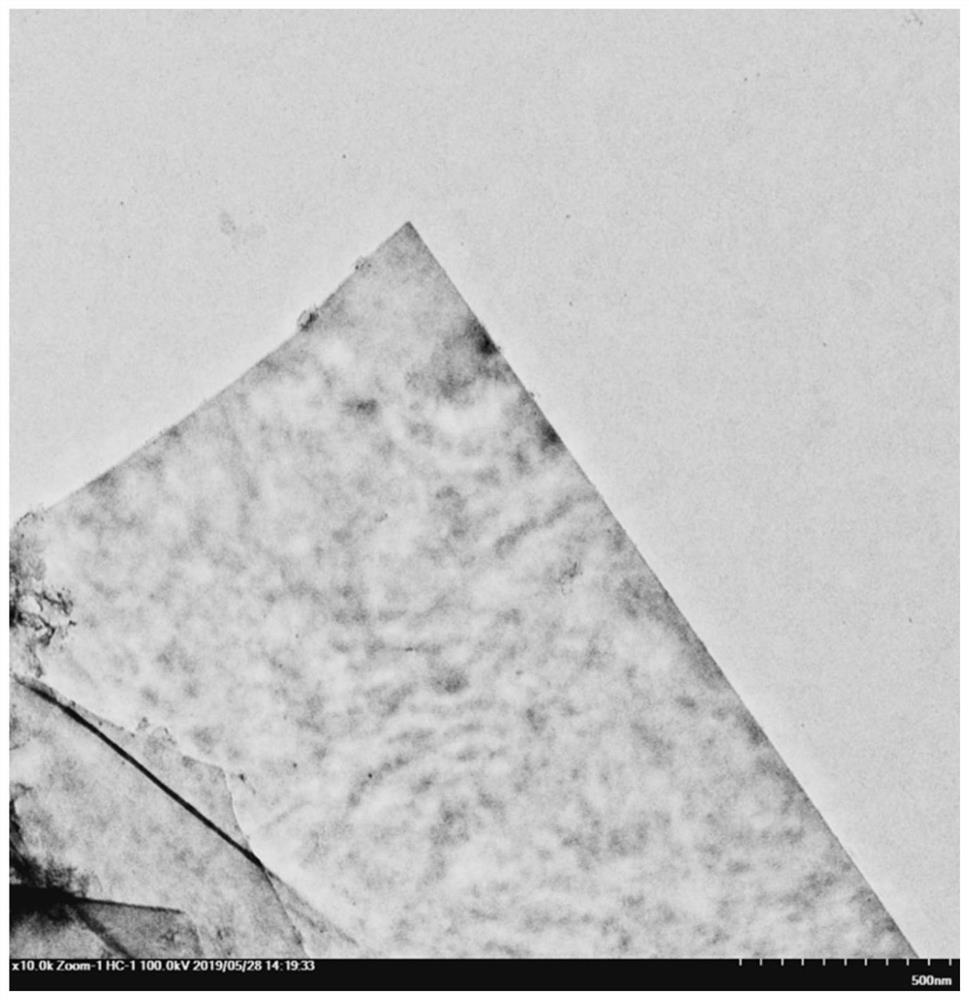

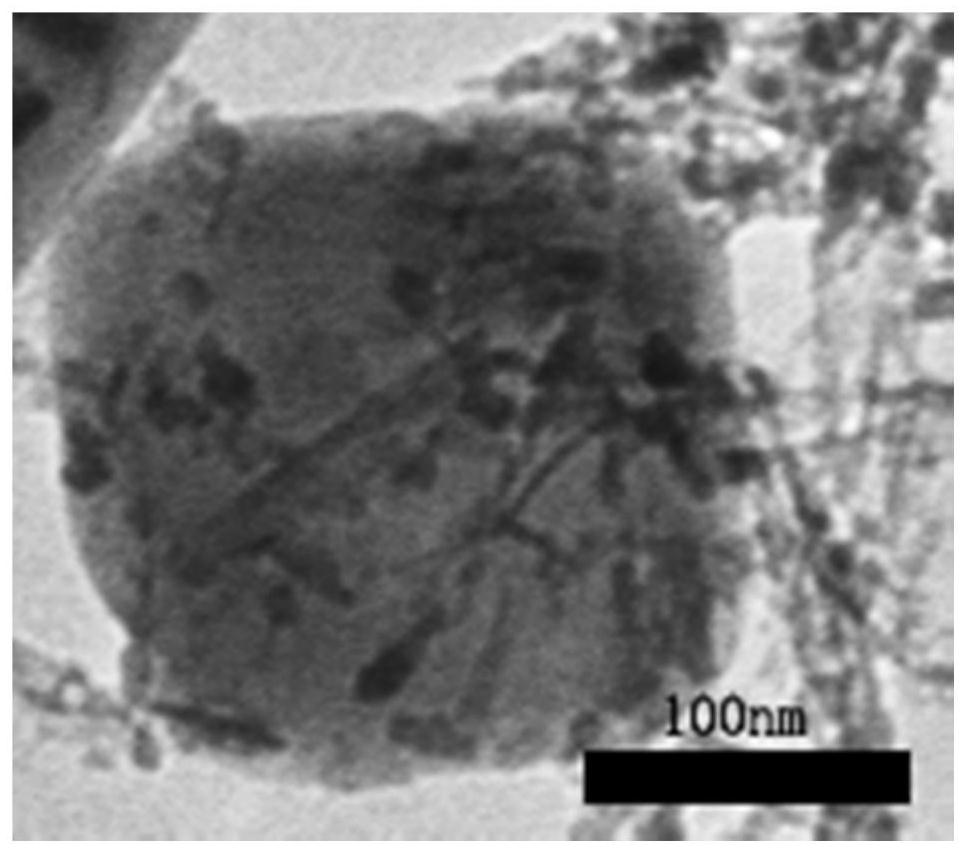

[0033] A kind of preparation method of MXene / titanium dioxide nanotube composite material photocatalyst, comprises the following steps:

[0034] a) Preparation of MXene materials:

[0035] Add LiF to 8-10mol / L hydrochloric acid solution and mix evenly, add Ti 3 AlC 2 Solid powder and mix evenly, each 30mL hydrochloric acid solution corresponds to 0.7-0.9g LiF powder and 0.9-1.2g Ti 3 AlC 2 Solid powder, 30~40℃ constant temperature reaction for 44~52 hours to get the reaction product, wash the reaction product until neutral, disperse the washed product in water, pass through N 2 / Ar and ultrasonic for 2 to 4 hours, centrifuge the product after ultrasonic treatment and take the supernatant, add 0.8 to 1.2 mol / L sodium hydroxide solution with a concentration equal to the volume of the supernatant to the supernatant, and let stand to obtain Precipitate, wash the precipitate to neutrality, and freeze-dry to obtain MXene material (monolayer MXene material);

[0036] b) Preparat...

Embodiment 1

[0039] a) Preparation of MXene:

[0040] 1) Prepare 30ml of HCl solution with a concentration of 9mol / L in a polytetrafluoroethylene beaker, weigh 0.8g of LiF powder into it, stir and mix evenly;

[0041] 2) Weigh 1g Ti 3 AlC 2 For solid powder, slowly add the above solution several times, stir and mix evenly, put it in an oil bath at 35°C and stir for 48 hours at a constant temperature;

[0042] 3) Use a high-speed centrifuge to wash the product after the reaction at a speed of 4000 rpm to remove the mucus, and then wash it repeatedly with distilled water until neutral;

[0043] 4) Disperse all the mucus washed to neutral in 100mL H 2 O, pass N 2 / Ar, ultrasonic for 2.5 hours at the same time, and then the sample solution was centrifuged at 4000rpm for 1 hour;

[0044] 5) After centrifugation, take the upper layer solution and add an equal volume of 1mol / L NaOH solution, flocculate, let it stand for 3 hours to obtain a precipitate, wash the precipitate with distilled water...

Embodiment 2

[0052] a) Preparation of MXene:

[0053] 1) Prepare 30ml of HCl solution with a concentration of 8mol / L in a polytetrafluoroethylene beaker, weigh 0.9g of LiF powder into it, stir and mix evenly;

[0054] 2) Weigh 1.2g Ti 3 AlC 2 For solid powder, slowly add the above solution several times, stir and mix evenly, put it in an oil bath at 30°C and stir for 44 hours at a constant temperature;

[0055] 3) Use a high-speed centrifuge to wash the product after the reaction at a speed of 4000 rpm to remove the mucus, and then wash it repeatedly with distilled water until neutral;

[0056] 4) Disperse all the mucus washed to neutral in 100mL H 2 O, pass N 2 / Ar, ultrasonic for 2 hours at the same time, and then the sample solution was centrifuged at 4000rpm for 1 hour;

[0057] 5) After centrifugation, take the upper layer solution and add an equal volume of 0.8mol / L NaOH solution, flocculate, let it stand for 3 hours to obtain a precipitate, wash the precipitate with distilled w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com