Mechanical arm production aluminum profile rinsing device

A flushing device and aluminum profile technology, applied in the field of manipulators, can solve problems such as complex production of manipulators, uneven washing, poor cleaning effect, etc., and achieve the effect of reducing enterprise production expenses, reducing flushing water consumption, and good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

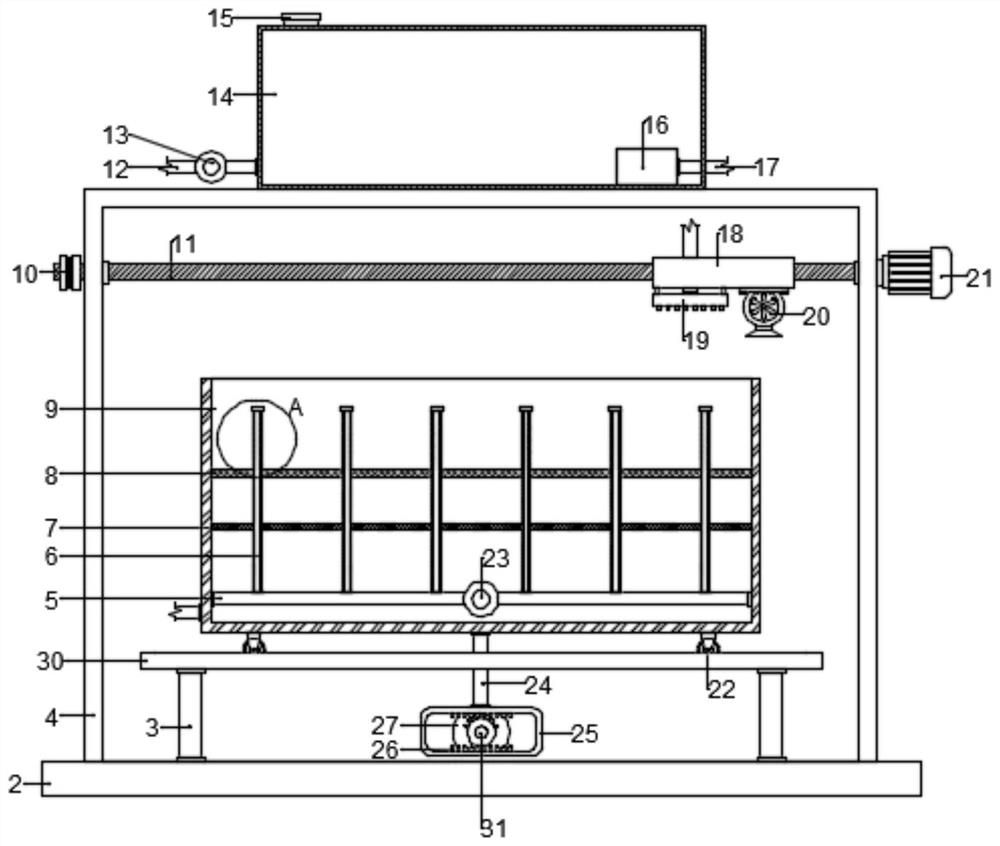

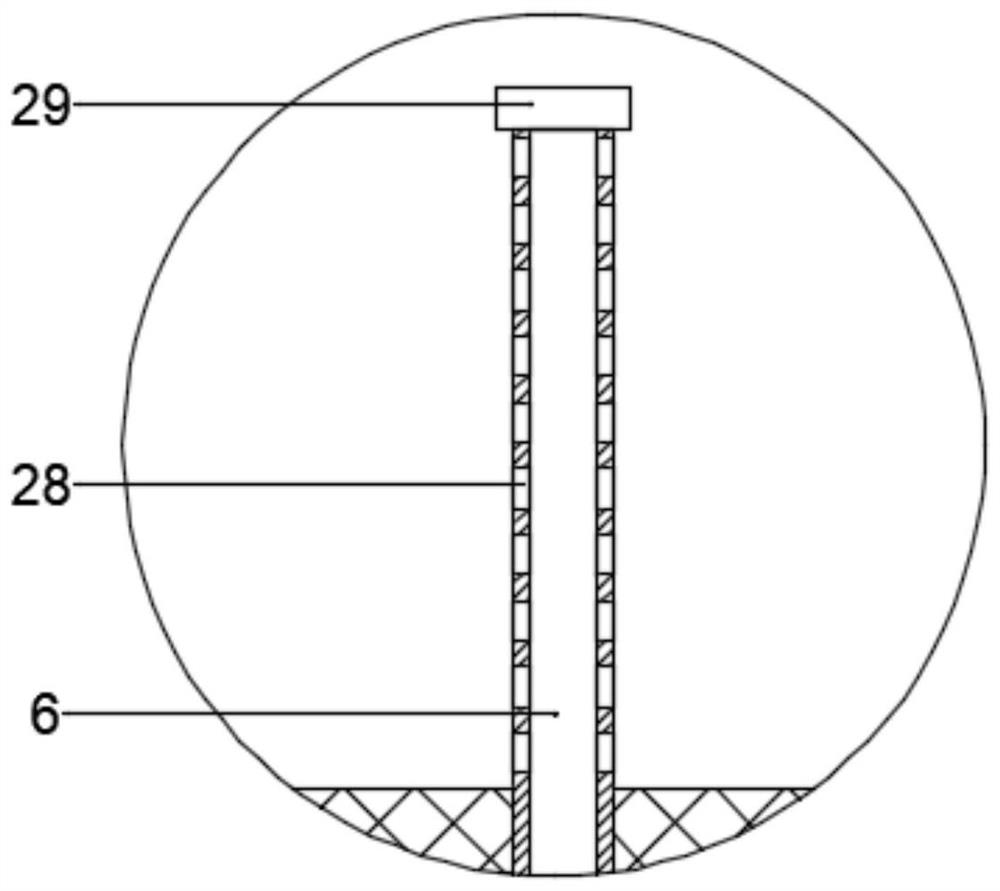

[0021] see figure 1 and figure 2 , in an embodiment of the present invention, an aluminum profile washing device for manipulator production, including a base 2, a U-shaped plate 4 and a bearing platform 30, the U-shaped plate 4 is fixedly installed on the base 2, and the bearing platform 30 is supported by a plurality of The rod 3 is fixedly installed on the top of the base 2, and a flushing box 9 is movable on the bearing platform 30. The flushing box 9 is provided with a mesh plate 8 and a filter screen 7 in turn from top to bottom, and the bottom of the flushing box 9 is symmetrically provided with multiple guides. The pulley 22 and the carrying platform 30 are provided with the same number of draw-in slots as the guide wheels 22 at the bottom of the flushing tank 9, and each guide wheel 22 is stuck in a draw-in slot close to it, and the bottom of the flushing tank 9 inner cavity is provided with a main water pipe 5 , the main water pipe 5 is equidistantly embedded with a...

Embodiment 2

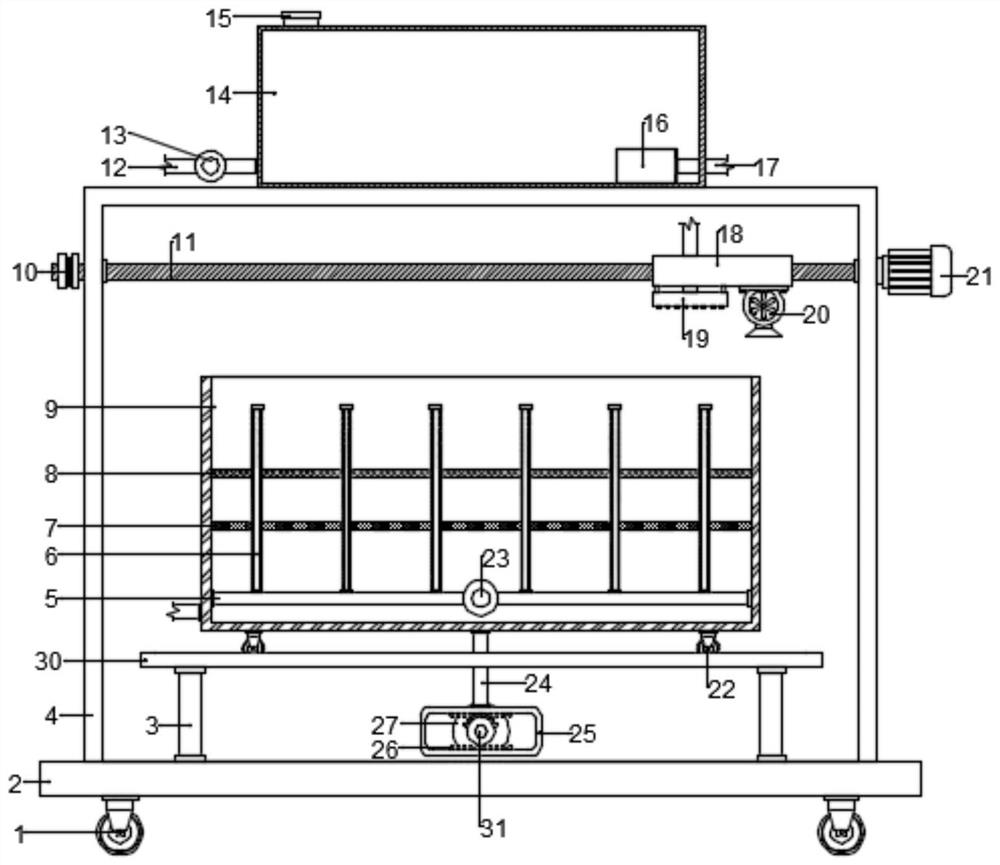

[0028] see image 3 The difference between the embodiment of the present invention and embodiment 1 is that further, in order to facilitate the movement of the device, the bottom of the base 2 is symmetrically provided with a plurality of rollers 1, and the rollers 1 are self-locking rollers. Roller 1 can move this device easily and conveniently, simple and trouble-free, convenient and practical.

[0029]The working principle of the present invention is: when the present invention is in use, the aluminum profile that needs to be flushed is placed on the mesh plate 8 in the flushing box 9, and then an appropriate amount of water is injected into the water storage tank 14 and the flushing box 9, and then Start the water return pump 13, the water outlet pump 16, the rotating motor 21, the water delivery pump 23 and the driving motor 27, and the driving motor 27 drives the brake lever 24 to move left and right so that the flushing box 9 is circulated left and right as a whole, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com