Silicon wafer acid cutting method adopting double-state circulation enrichment technology

A cutting method, enrichment technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

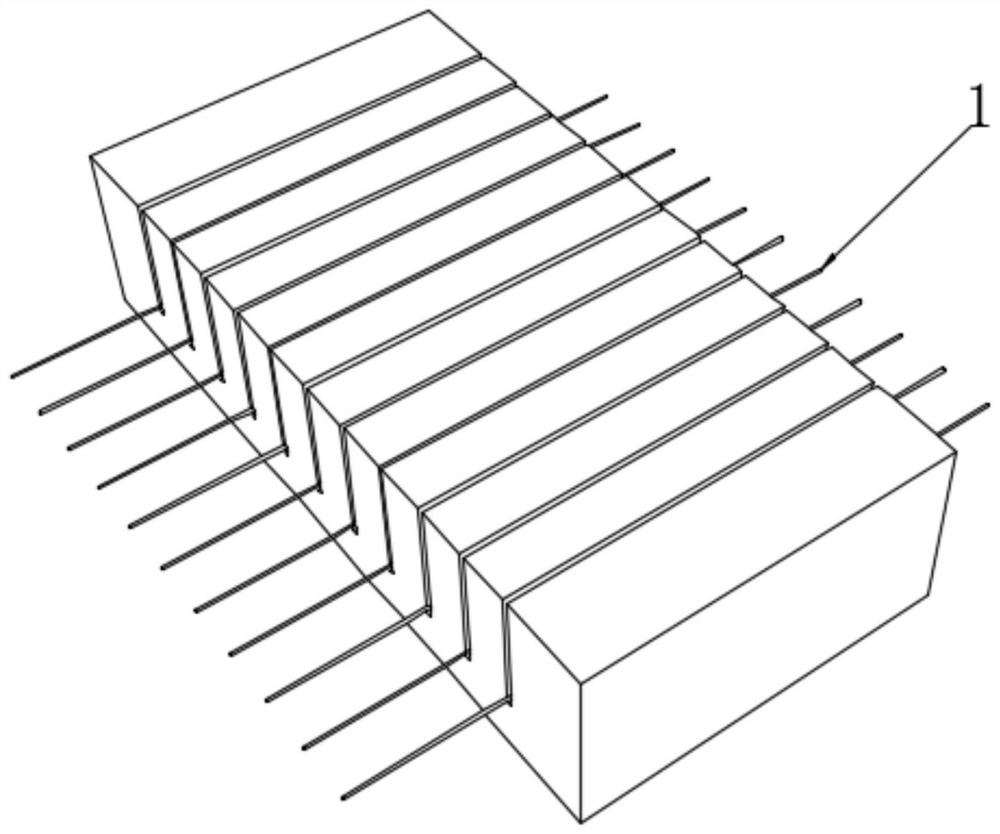

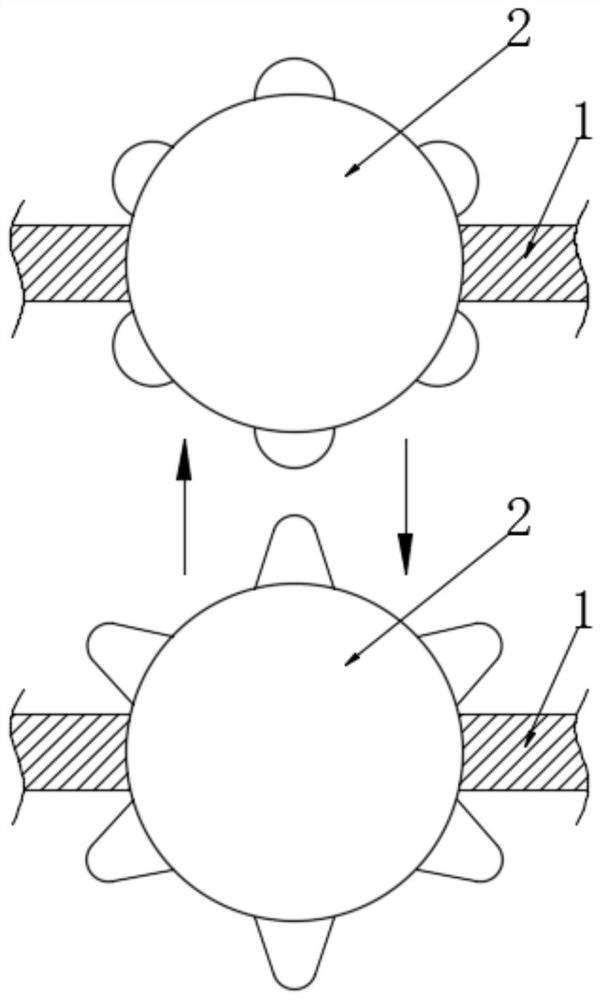

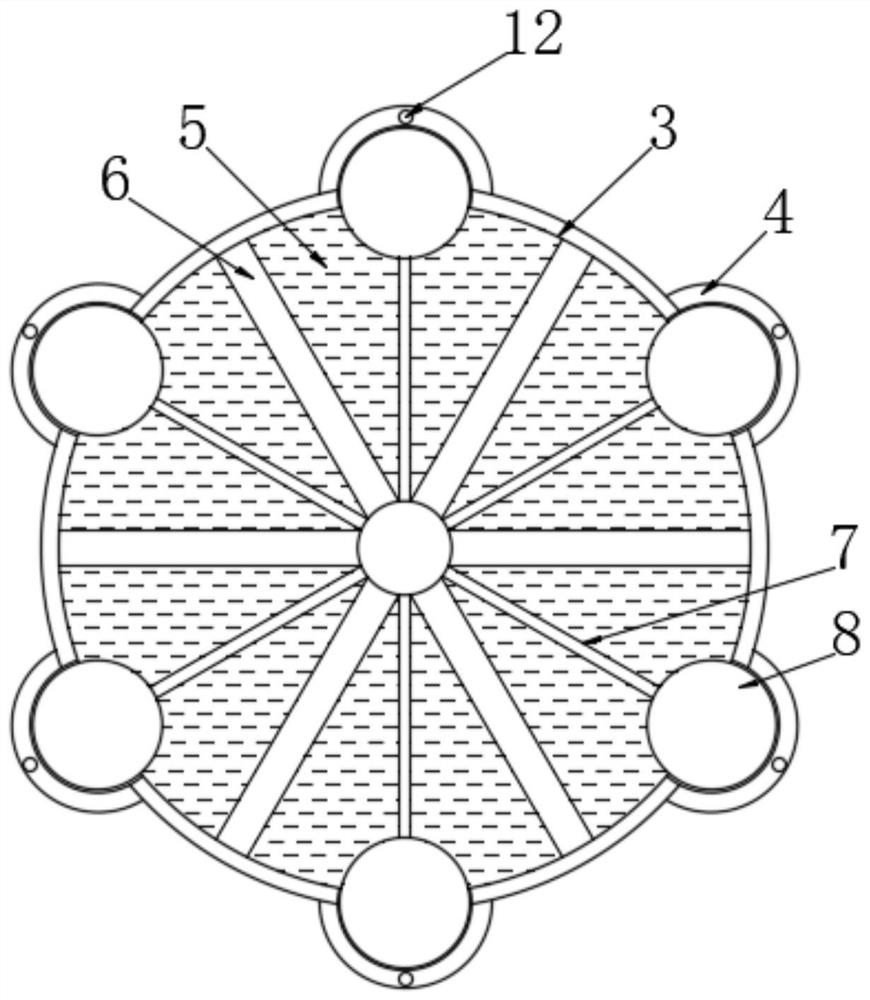

[0043] See figure 1 , A method for acidic cutting of silicon wafers with two-state cycle enrichment technology, including the following steps:

[0044] S1. Use semiconductor refrigeration chips to heat the volatile acid solution to 50°C to generate hydrogen chloride gas and water vapor. At the same time, use semiconductor refrigeration chips to cool the modified cutting steel wire;

[0045] S2. Contact the volatile acid gas and water vapor obtained by heating with the modified cutting steel wire to liquefy the volatile acid gas and water vapor on its surface and re-enrich a large amount of volatile acid solution;

[0046] S3. Use a modified steel wire rope enriched with a large amount of volatile acid solution to cut a large silicon wafer, and use the corrosive effect of volatile acid to separate the large silicon wafer into several small silicon wafers.

[0047] The volatile acid solution in S1 is any one or more of hydrochloric acid, hydrofluoric acid and nitric acid. By setting the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com