Electric forklift low-temperature type lithium battery management system and control method thereof

A technology of electric forklifts and management systems, applied in battery/fuel cell control devices, electric vehicles, battery circuit devices, etc., can solve the problems of slow ion migration rate, shortened continuous running time, and reduced chemical reaction rate, etc., to achieve improved Effects of electrochemical performance, improved electrochemical performance, and improved operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

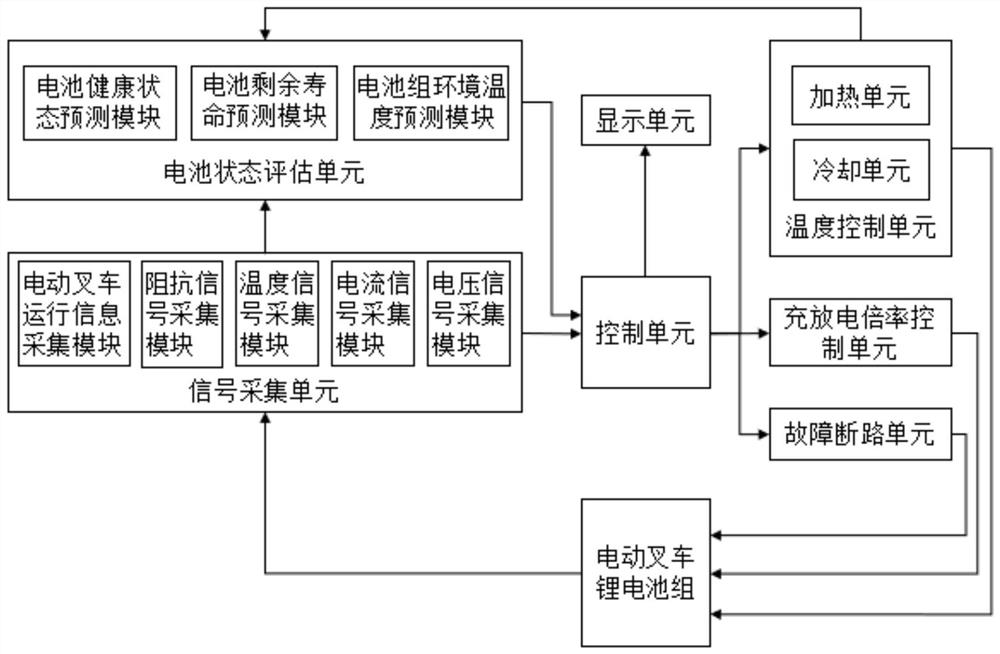

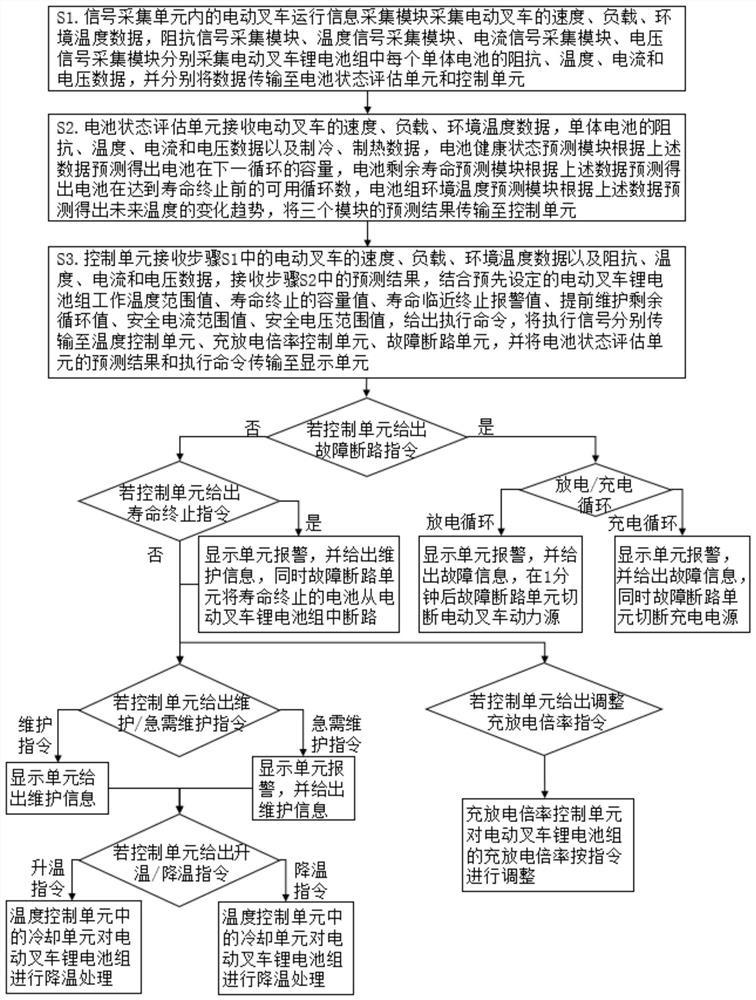

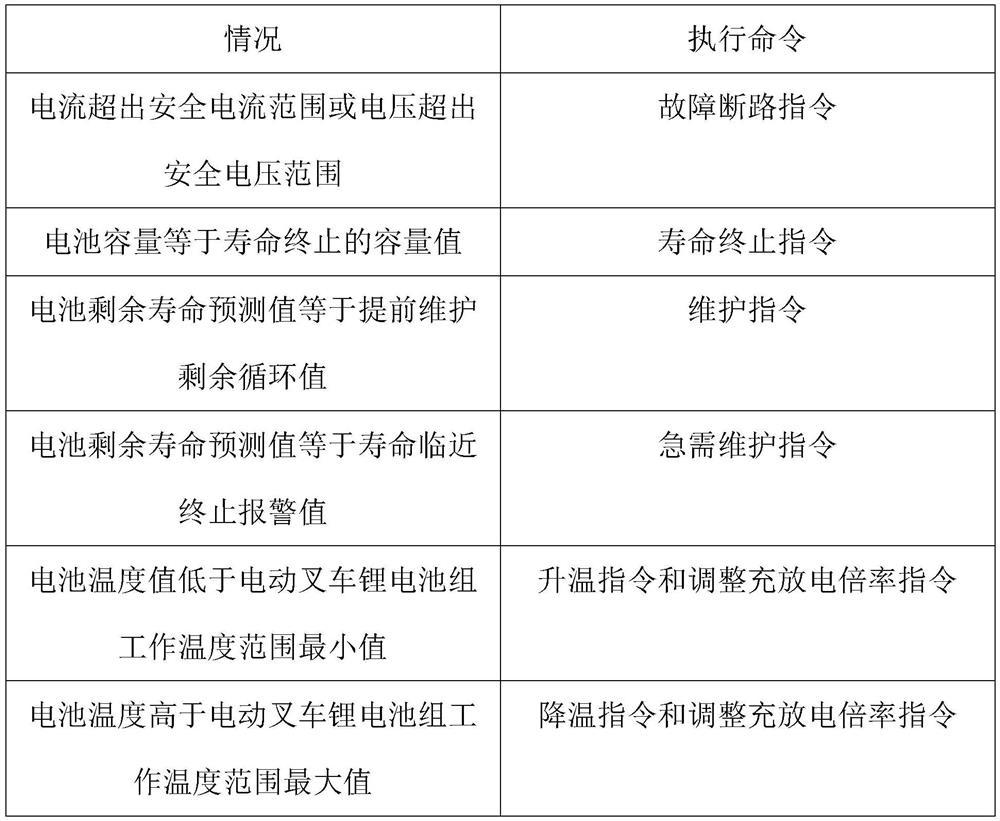

[0031] Such as figure 1 , figure 2 In the shown embodiment, a low-temperature lithium battery management system for an electric forklift and its control method, wherein the low-temperature lithium battery management system for an electric forklift has the following structure: including a control unit, a display unit, a signal acquisition unit, a battery status evaluation unit, Temperature control unit, charge and discharge rate control unit, fault interruption unit and electric forklift lithium battery pack, the connection relationship is that the signal input end of the signal acquisition unit is connected with the electric forklift lithium battery pack, and the signal output end of the signal acquisition unit is connected with the input of the battery status evaluation unit terminal and the input terminal of the control unit, the output ter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com