Recovery method of waste lithium iron phosphate battery positive electrode material

A technology of lithium iron phosphate battery and cathode material, which is applied in battery recycling, waste collector recycling, secondary battery and other directions, can solve the problems of poor recycling effect of iron and phosphorus elements, and achieve low cost, simple operation and environmental friendliness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

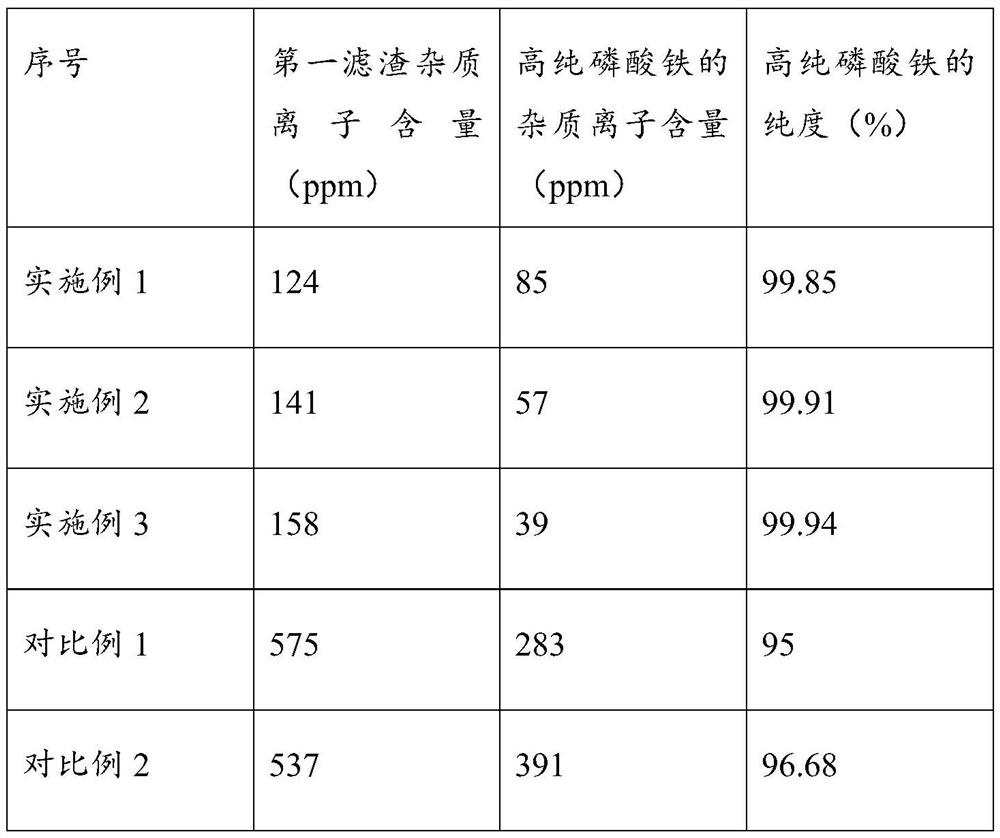

Examples

Embodiment 1

[0029] A method for recycling the positive electrode material of a waste lithium iron phosphate battery, comprising the steps of:

[0030] (1) After the waste lithium iron phosphate battery has been discharged with residual power, disassemble the battery, separate the positive plate, add N-methylpyrrolidone to the positive plate to dissolve the binder, separate the current collector, and clean the rest of the solid Filter, wash, and dry the waste to obtain waste cathode materials;

[0031] Take 10g of the above waste positive electrode material and add 50mL, 20wt% nitric acid aqueous solution to dissolve, filter to obtain the first filtrate;

[0032] (2) Heat the above-mentioned first filtrate at 50°C for 2h to completely oxidize the ferrous ions in the first filtrate, then add 4mL of ammonia water to adjust the pH of the system to 2, and continue to heat the reaction at 70°C for 1h, filter, obtaining the first filter residue and lithium-containing filtrate; concentrating the...

Embodiment 2

[0036]A method for recycling the positive electrode material of a waste lithium iron phosphate battery, comprising the steps of:

[0037] (1) extract the waste lithium iron phosphate positive electrode material according to the method of Example 1; take 15g of the waste lithium iron phosphate positive electrode material, add 15mL, 30wt% nitric acid solution to dissolve, filter to obtain the first filtrate;

[0038] (2) Heat the above first filtrate at 80°C for 2.5h to completely oxidize the ferrous ions in the first filtrate, then add 3mL of ammonia water to adjust the pH of the solution to 1.5, continue heating and reacting at 80°C for 3h, and filter to obtain The first filter residue and lithium-containing filtrate;

[0039] According to the method of Example 1, the first filter residue was washed 3 times with a shear emulsification pump to obtain high-purity ferric phosphate, and the lithium-containing filtrate was concentrated for later use;

[0040] (3) Liquid-phase synt...

Embodiment 3

[0042] A method for recycling the positive electrode material of a waste lithium iron phosphate battery, comprising the steps of:

[0043] (1) extract the waste lithium iron phosphate positive electrode material according to the method of Example 1; take 12g of the waste lithium iron phosphate positive electrode material, add 40mL, 10wt% nitric acid solution to dissolve, filter to obtain the first filtrate;

[0044] (2) Heat the above first filtrate at 90°C for 3h to completely oxidize the ferrous ions in the first filtrate, then add 5mL of ammonia water to adjust the pH of the solution to 1, continue heating and reacting at 60°C for 2h, and filter to obtain the first - filter residue and lithium-containing filtrate;

[0045] According to the method of Example 1, the first filter residue was washed 3 times with a shear emulsification pump to obtain high-purity ferric phosphate, and then heat-treated at 300°C for 4 hours to transform into crystalline ferric phosphate; the lithi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com