Polyethyleneimine reinforced graphene insensitive energetic material and preparation method thereof

A technology of polyethyleneimine and graphene, applied in the direction of non-explosive desensitizer/passivator, offensive equipment, explosive processing equipment, etc., can solve the problems of reduced desensitization effect, weak interaction, easy peeling, etc., to achieve Improved coating effect, strong universality and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

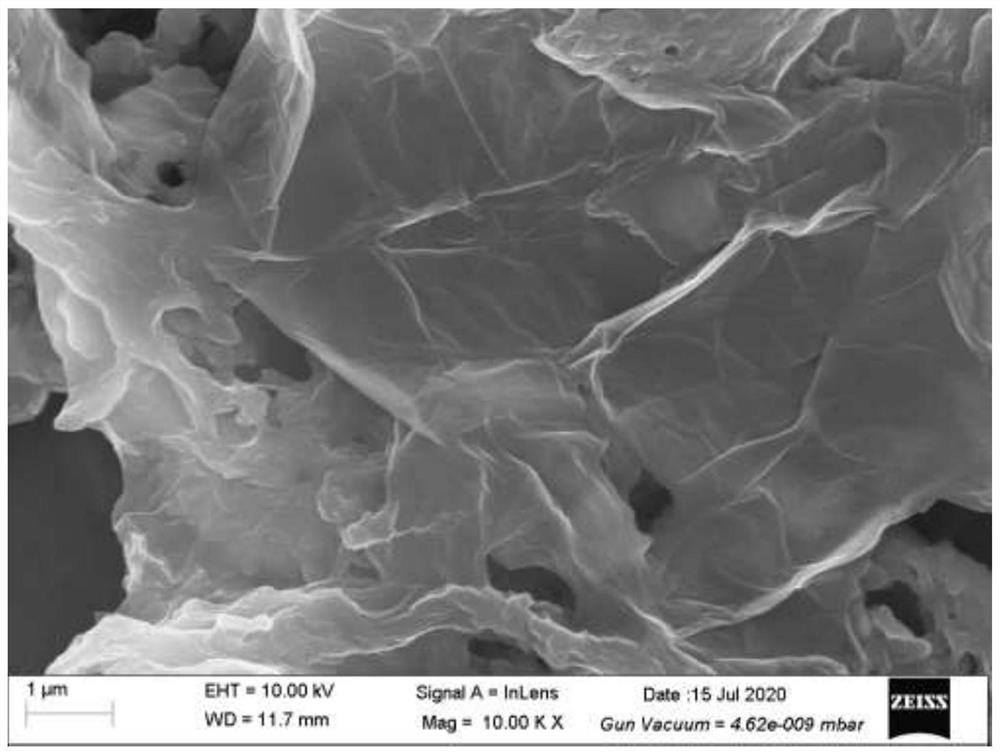

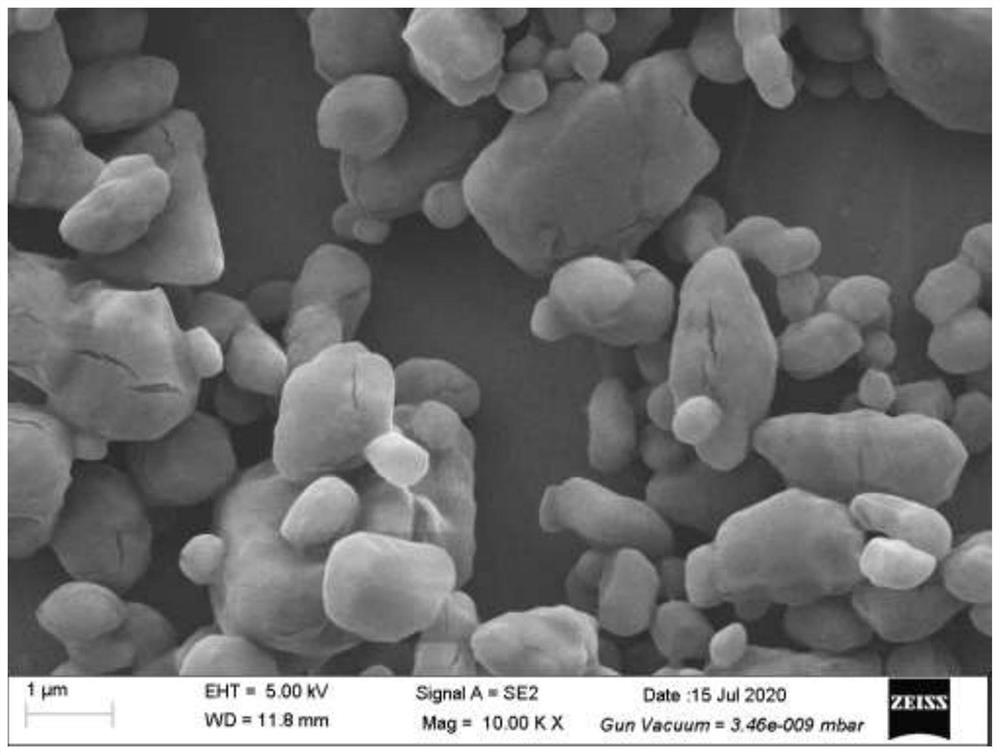

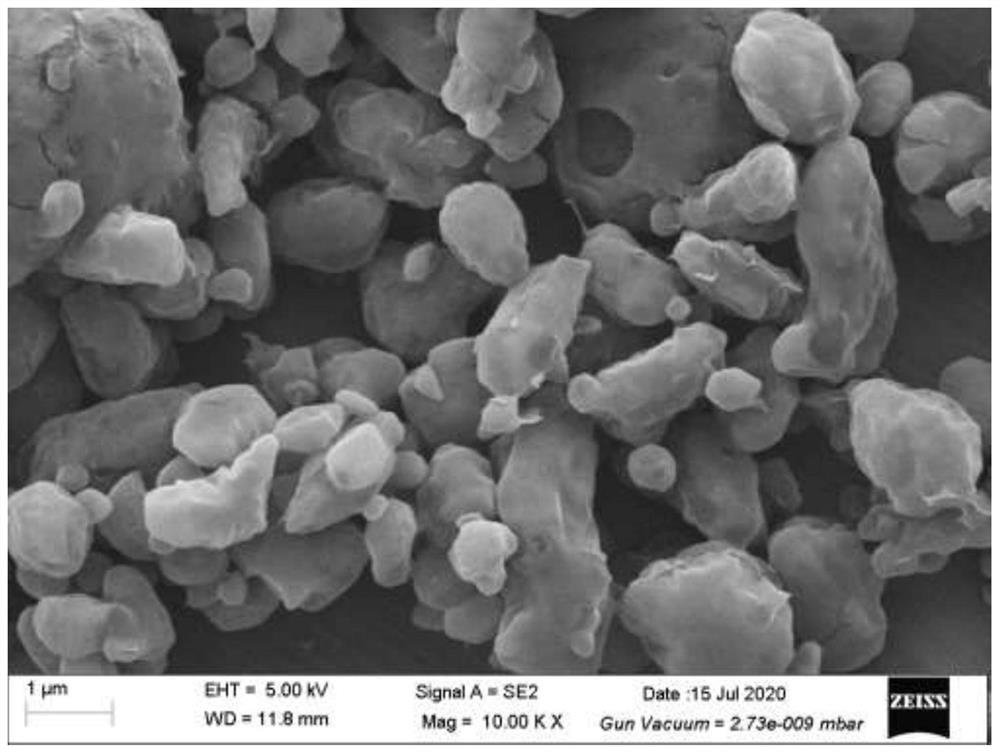

Embodiment 1

[0031] Disperse 0.490 g of CL-20 in 30 ml H 2 Ultrasound in O for 2.0 h, and then dropwise add 4 mL of PEI (molecular weight 600) aqueous solution with a concentration of 0.5 g / L. After stirring at room temperature for 4 h, 16 mL of 0.5 g / L GO dispersion was added dropwise, and the stirring was continued for 10 h. The reaction solution was filtered, the filter cake was washed 8 times with ultrapure water, and dried in a vacuum oven at 60°C for 24 hours to obtain the CL-20 / PEI / GO composite energetic material. The impact sensitivity is 1.6J (the raw material CL-20 is 0.7J), and the friction sensitivity is 96N (the raw material CL-20 is 48N).

Embodiment 2

[0033] Disperse 0.490 g of CL-20 in 30 ml H 2 Ultrasound in O for 2.0 h, and then dropwise add 4 mL of PEI (molecular weight 1800) aqueous solution with a concentration of 0.5 g / L. After stirring at room temperature for 4 h, 16 mL of 0.5 g / L GO dispersion was added dropwise, and the stirring was continued for 10 h. The reaction solution was filtered, the filter cake was washed 8 times with ultrapure water, and dried in a vacuum oven at 60°C for 24 hours to obtain the CL-20 / PEI / GO composite energetic material. The impact sensitivity is 2.6J (the raw material CL-20 is 0.7J), and the friction sensitivity is 128N (the raw material CL-20 is 48N).

Embodiment 3

[0035] Disperse 0.490 g of CL-20 in 30 ml H 2 Ultrasound in O for 2.0 h, and then dropwise add 4 mL of PEI (molecular weight: 10,000) aqueous solution with a concentration of 0.5 g / L. After stirring at room temperature for 4 h, 16 mL of GO dispersion with a concentration of 0.5 g / L was added dropwise, and the stirring was continued for 10 h. The reaction solution was filtered, the filter cake was washed 8 times with ultrapure water, and dried in a vacuum oven at 60°C for 24 hours to obtain the CL-20 / PEI / GO composite energetic material. The impact sensitivity is 3.4J (the raw material CL-20 is 0.7J), and the friction sensitivity is 144N (the raw material CL-20 is 48N).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact sensitivity | aaaaa | aaaaa |

| Impact sensitivity | aaaaa | aaaaa |

| Friction sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com