Amphiphilic polymelphalan prodrug micelle and preparation method thereof

A melphalan and amphiphilic technology, which is applied in the field of amphiphilic polymelphalan prodrug micelles and its preparation, can solve the problems of high toxicity and side effects, and achieve low cost, controllable structure, and easy industrialization The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

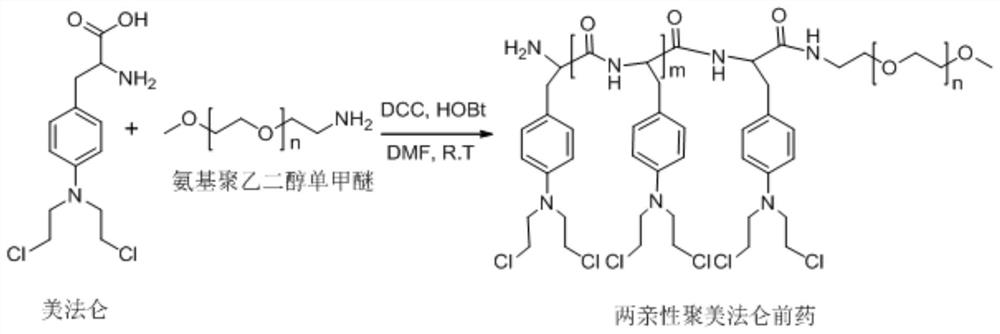

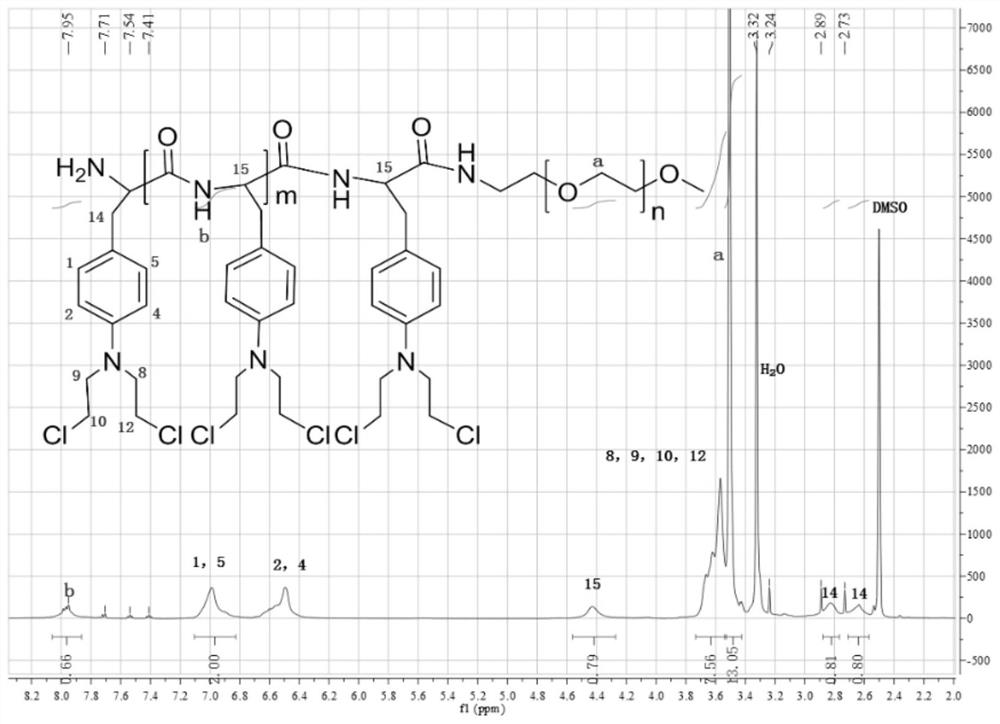

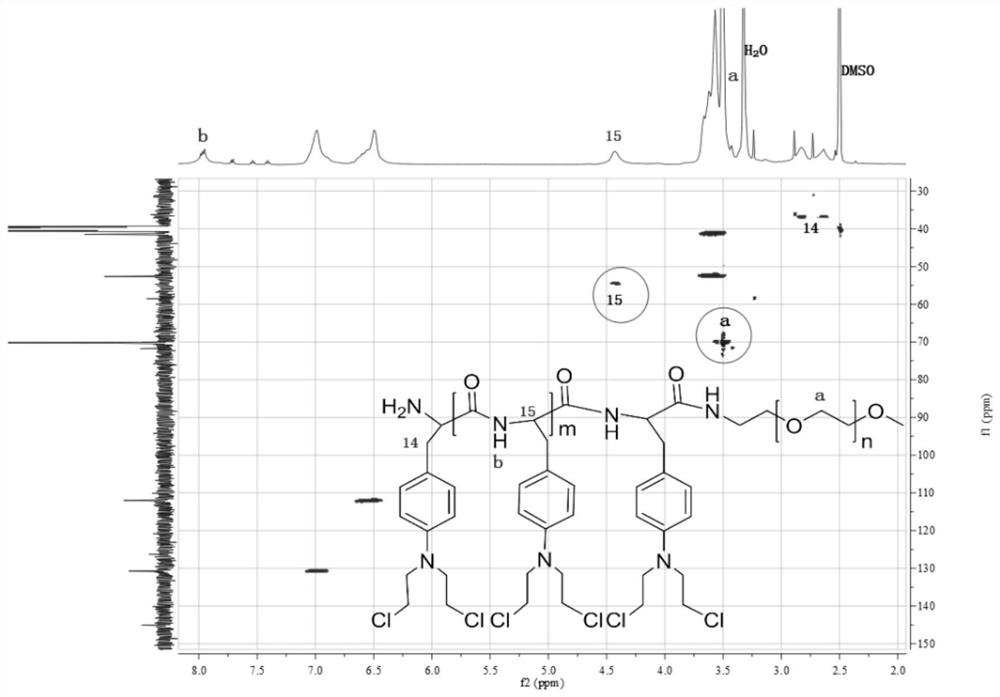

Method used

Image

Examples

Embodiment 1

[0030] A preparation method of amphiphilic polymelphalan prodrug micelles, comprising the following steps:

[0031] Put 1mmol antineoplastic drug melphalan and 0.05mmol aminopolyethylene glycol monomethyl ether (molecular weight 2000) in a round bottom flask, add DCC and HOBT in equimolar ratio with melphalan, that is, melphalan and DCC , The mol ratio of HOBT is 1:1:1; Add anhydrous DMF and molecular sieve afterwards, the mass ratio of melphalan and anhydrous DMF is 1:40;

[0032] After two days of reaction in anhydrous and oxygen-free room temperature, the reaction solution was transferred to a dialysis bag. After three days of dialysis with DMF, DMF was changed three times during the period, and the dialysis was continued in pure water for two days, and the pure water was changed several times during the period.

[0033] After dialysis, freeze-dry to obtain amphiphilic polymelphalan prodrug micelles.

Embodiment 2

[0035] A preparation method of amphiphilic polymelphalan prodrug micelles, comprising the following steps:

[0036] Put 1mmol antineoplastic drug melphalan and 0.02mmol aminopolyethylene glycol monomethyl ether (molecular weight 2000) in a round bottom flask, add DCC and HOBT in equimolar ratio with melphalan, that is, melphalan and DCC , The mol ratio of HOBT is 1:1:1; Add anhydrous DMF and molecular sieve afterwards, the mass ratio of melphalan and anhydrous DMF is 1:50;

[0037] After two days of reaction in anhydrous and oxygen-free room temperature, the reaction solution was transferred to a dialysis bag. After three days of dialysis with DMF, DMF was changed three times during the period, and the dialysis was continued in pure water for two days, and the pure water was changed several times during the period.

[0038] After dialysis, freeze-dry to obtain amphiphilic polymelphalan prodrug micelles.

Embodiment 3

[0040] A preparation method of amphiphilic polymelphalan prodrug micelles, comprising the following steps:

[0041] Put 1mmol antineoplastic drug melphalan and 0.1mmol aminopolyethylene glycol monomethyl ether (molecular weight 2000) in a round bottom flask, add DCC and HOBT in equimolar ratio with melphalan, that is, melphalan and DCC , The mol ratio of HOBT is 1:1:1; Add anhydrous DMF and molecular sieve afterwards, the mass ratio of melphalan and anhydrous DMF is 1:30;

[0042] After two days of reaction in anhydrous and oxygen-free room temperature, the reaction solution was transferred to a dialysis bag. After three days of dialysis with DMF, DMF was changed three times during the period, and the dialysis was continued in pure water for two days, and the pure water was changed several times during the period.

[0043] After dialysis, freeze-dry to obtain amphiphilic polymelphalan prodrug micelles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com