Crosslinked polyvinyl chloride material and preparation method thereof

A technology of cross-linked polyvinyl chloride and cross-linking agent, which is applied in the field of cross-linked PVC materials and its preparation, can solve the problems of poor heat resistance of PVC materials, achieve obvious heat resistance, accelerate cross-linking rate, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

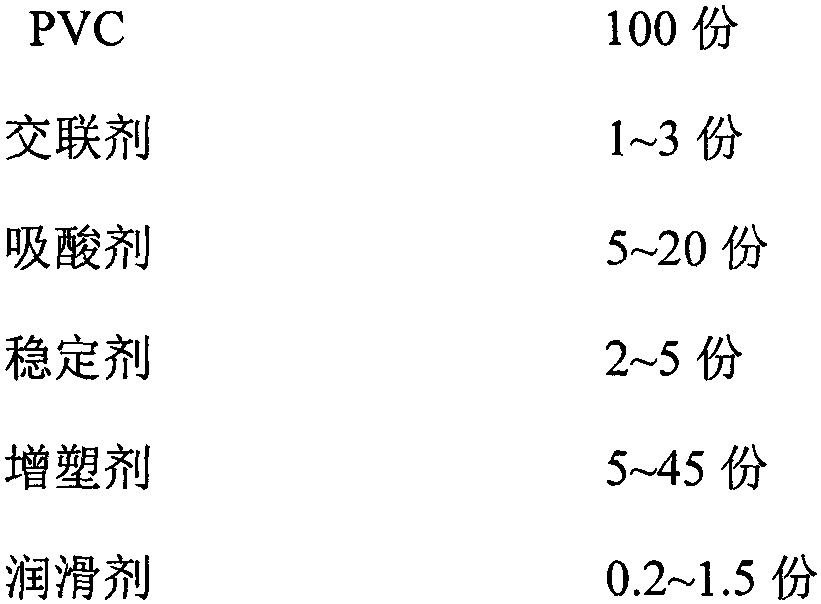

[0026] This embodiment proposes a cross-linked PVC material, and its raw material formula weight components are as follows:

[0027]

[0028] The degree of polymerization of the PVC resin is 1,000. The crosslinking agent is triazole dimercaptoammonium salt (FSH). The acid absorbent is magnesium oxide. The stabilizer is a calcium zinc stabilizer. The plasticizer is dioctyl phthalate. The lubricant is stearic acid.

[0029] The preparation method of the cross-linked PVC material described in this embodiment includes the following steps:

[0030] (1) Weigh various raw materials according to the formula and put them into a high-speed mixer for high-speed mixing to make them evenly mixed, and the time is 10 minutes to prepare a mixture.

[0031] (2) Melt and blend the mixture in a two-roll plastic mill, the temperature of the front roll is 150°C, the temperature of the back roll is 155°C, the plasticizing time is 3min, and then the sheet is discharged.

[0032] (3) The temperature of th...

Embodiment 2

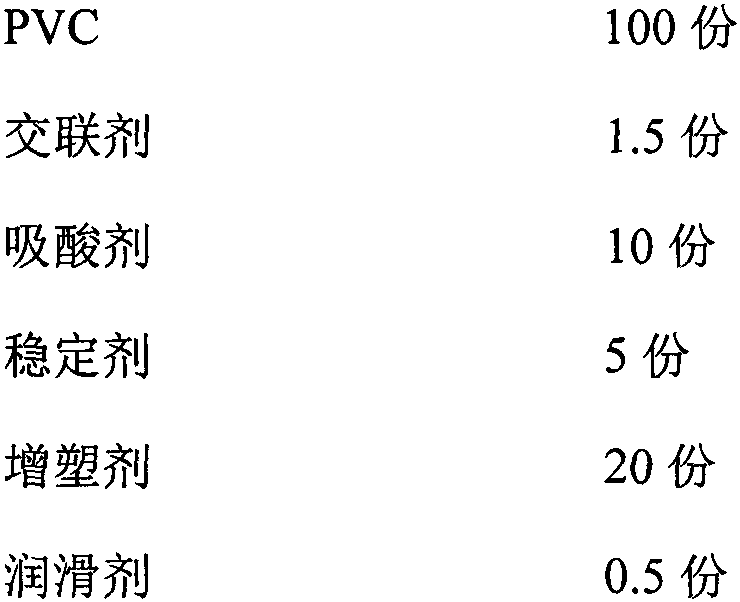

[0036] This embodiment proposes a cross-linked PVC material, and its raw material formula weight components are as follows:

[0037]

[0038]

[0039] The degree of polymerization of the PVC resin is 800. The crosslinking agent is 2-n-butylamine-4,6-dimercapto-s-triazine (DB). The acid absorbent is barium oxide. The stabilizer is lead stearate. The plasticizer is epoxy soybean oil. The lubricant is paraffin wax.

[0040] The preparation method of the cross-linked PVC material described in this embodiment includes the following steps:

[0041] (1) Weigh all the raw materials according to the formula and put them in a high-speed mixer for high-speed mixing to make them evenly mixed. The time is 15 minutes to prepare a mixture.

[0042] (2) Melt and blend the mixture in a two-roll plastic mill, the temperature of the front roll is 155°C, the temperature of the back roll is 160°C, the plasticizing time is 3min, and then the sheet is discharged.

[0043] (3) The temperature of the plate...

Embodiment 3

[0047] This embodiment proposes a cross-linked PVC material, and its raw material formula weight components are as follows:

[0048]

[0049] The degree of polymerization of the PVC resin is 1,000. The crosslinking agent is triazole dimercaptoammonium salt (FSH). The acid absorbent is magnesium oxide. The stabilizer is a rare earth stabilizer. The plasticizer is dioctyl phthalate. The lubricant is stearic acid.

[0050] The preparation method of the cross-linked PVC material described in this embodiment includes the following steps:

[0051] (1) Weigh all the raw materials according to the formula and put them into a high-speed mixer for high-speed mixing to make them evenly mixed. The time is 12 minutes to prepare a mixture.

[0052] (2) Melt and blend the mixture in a two-roll plastic mill, the temperature of the front roll is 160°C, the temperature of the back roll is 165°C, the plasticizing time is 3min, and then the sheet is discharged.

[0053] (3) The temperature of the plat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| gel rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com