Metallurgical slag recovery treatment method

A technology for recycling and processing metallurgical slag, applied in the chemical industry, can solve the problems of affecting the environment, ineffective treatment and recycling, large amount of metallurgical slag, etc., and achieve the effects of reducing accumulation and discharge, low equipment requirements and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

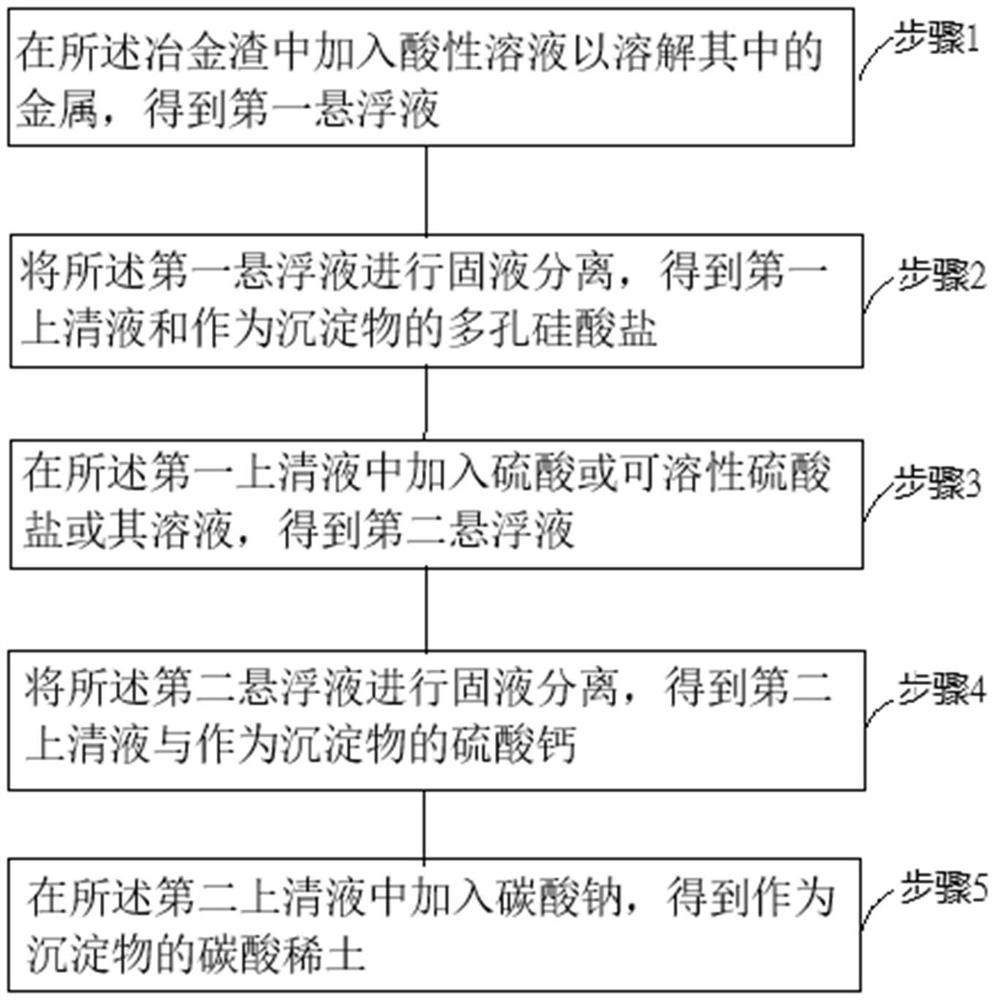

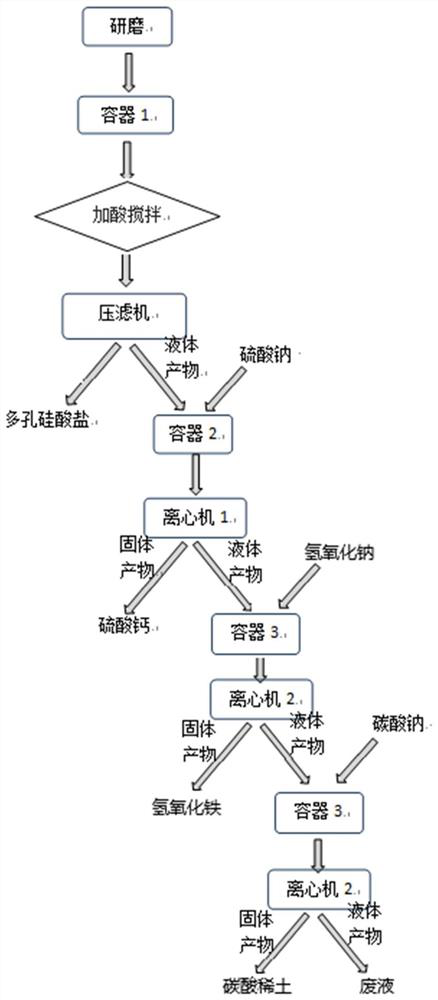

[0066] 1) Sorting the metallurgical slag to remove impurities, and then crushing and sieving to obtain a powder smaller than 80 mesh;

[0067] 2) adding acid and water to the powder, adjusting the pH value of the solution to 1.5, and dissolving the metal therein;

[0068] 3) performing solid-liquid separation through a filter press to obtain porous silicate and the first supernatant respectively;

[0069] 4) in the first supernatant, continue to add sodium sulfate, generate calcium sulfate precipitation, obtain the second suspension that is suspended with calcium sulfate precipitation;

[0070] 5) performing solid-liquid separation on the second suspension by a centrifuge to obtain calcium sulfate as a precipitate and a second supernatant;

[0071] 6) In the second supernatant, sodium hydroxide is added to generate iron hydroxide precipitation;

[0072] 7) further solid-liquid separation by centrifuge to obtain ferric hydroxide and residual liquid;

[0073] 8) Sodium carbon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com