System and method based on middle gas suction of compressor and used for liquefied air energy-storage peak regulation

A technology of liquefied air and compressors, which is applied in the direction of compressors, machine operation, and compressors with cascading work, etc. It can solve the problems of limited peak shaving capacity, reduced energy quality, and high average cost, and achieves deep reduction. Effect of cold production cost, reduction of energy transmission loss, reduction of investment and floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The patent of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. The specific embodiments described here are only used to explain the present invention, and are not intended to limit the present invention.

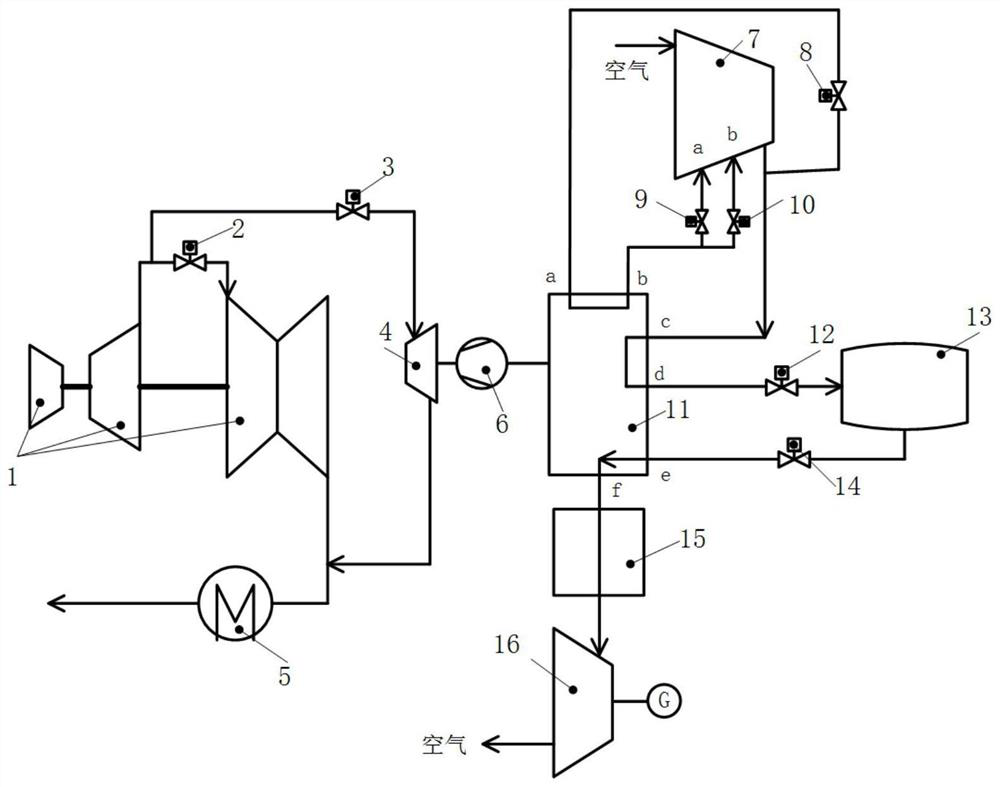

[0023] Such as figure 1 As shown, the present invention is based on a liquefied air energy storage peak-shaving system based on compressor mid-suction, consisting of a first steam turbine unit 1, a first valve 2, a second valve 3, a second steam turbine unit 4, a condenser 5, a refrigeration compression Machine 6, air compressor 7, third valve 8, fourth valve 9, fifth valve 10, cascade refrigeration / cold storage system 11, sixth valve 12, liquid air storage tank 13, seventh valve 14, air heating Device 15 and air expander 16 are formed.

[0024] The first steam turbine unit 1 includes a high-pressure cylinder, a medium-pressure cylinder and a low-pressure cylinder connected in sequ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com