Manufacturing method of anti-blue-ray spectacle lens

A production method and anti-blue light technology, which is applied in the field of optical eye lenses, can solve the problems of high cost, weak wear resistance and oil resistance, and difficulties in actual production, and achieve low cost, improved adhesion, and relieve visual fatigue. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

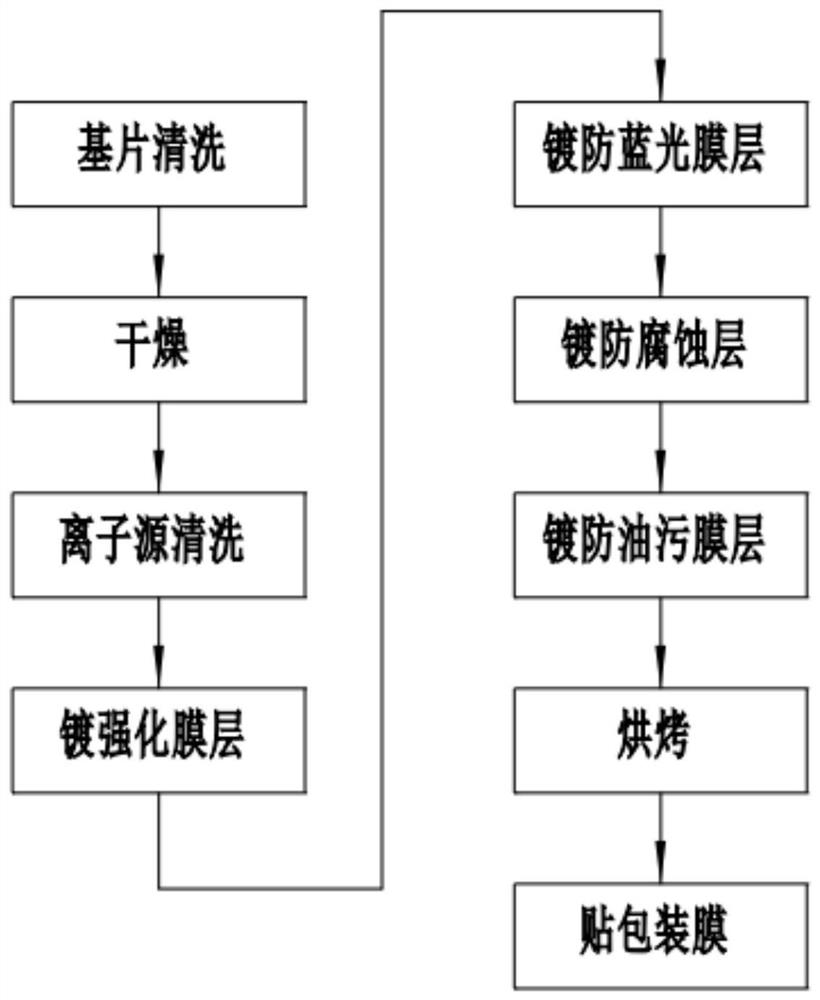

[0037] A method for manufacturing spectacle lenses with anti-blue light, comprising the following steps:

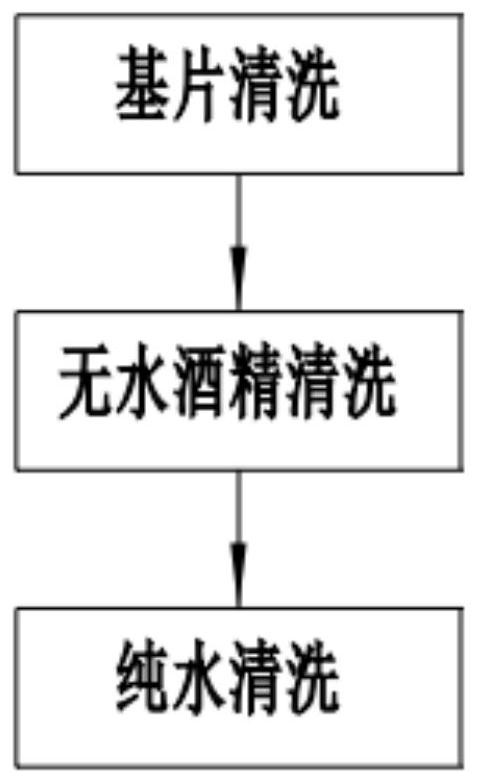

[0038] S1. Cleaning of the substrate: use an organic solvent to clean the substrate three times, and then use pure water to clean the substrate twice;

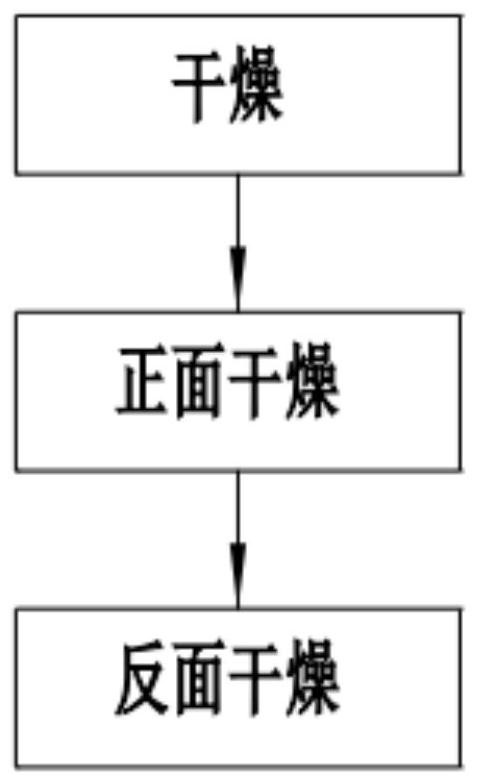

[0039] S2. Drying: quickly dry the substrate cleaned in S1 with a hot air blower;

[0040] S3. Ion source cleaning: place the dried substrate in S2 in the vacuum chamber of the electron beam evaporation machine, start the ion source to clean the substrate;

[0041] S4. Plating impact-resistant strengthening film layer: After the impact-resistant strengthening film material is evaporated by an electron gun, under the action of the ion source, the strengthening film material is deposited on the outer surface and inner surface of the substrate in the form of nano-scale molecules, so that the substrate The inner and outer surfaces form an impact-resistant strengthening film;

[0042] S5. Plating anti-blue light film layer: ...

Embodiment 2

[0057] A method for manufacturing spectacle lenses with anti-blue light, comprising the following steps:

[0058] S1. Cleaning of the substrate: use an organic solvent to clean the substrate three times, and then use pure water to clean the substrate twice;

[0059] S2. Drying: quickly dry the substrate cleaned in S1 with a hot air blower;

[0060] S3. Ion source cleaning: place the dried substrate in S2 in the vacuum chamber of the electron beam evaporation machine, start the ion source to clean the substrate;

[0061] S4. Plating impact-resistant strengthening film layer: After the impact-resistant strengthening film material is evaporated by an electron gun, under the action of the ion source, the strengthening film material is deposited on the outer surface and inner surface of the substrate in the form of nano-scale molecules, so that the substrate The inner and outer surfaces form an impact-resistant strengthening film;

[0062] S5. Plating anti-blue light film layer: ...

Embodiment 3

[0077] A method for manufacturing spectacle lenses with anti-blue light, comprising the following steps:

[0078] S1. Cleaning of the substrate: use an organic solvent to clean the substrate three times, and then use pure water to clean the substrate twice;

[0079] S2. Drying: quickly dry the substrate cleaned in S1 with a hot air blower;

[0080] S3. Ion source cleaning: place the dried substrate in S2 in the vacuum chamber of the electron beam evaporation machine, start the ion source to clean the substrate;

[0081] S4. Plating impact-resistant strengthening film layer: After the impact-resistant strengthening film material is evaporated by an electron gun, under the action of the ion source, the strengthening film material is deposited on the outer surface and inner surface of the substrate in the form of nano-scale molecules, so that the substrate The inner and outer surfaces form an impact-resistant strengthening film;

[0082] S5. Plating anti-blue light film layer: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com