Micro-size high-performance sintered neodymium-iron-boron magnet and preparation method thereof

A NdFeB micro-sized technology, applied in the direction of magnetic objects, inductor/transformer/magnet manufacturing, magnetic materials, etc., can solve the problems of insignificant diffusion effect, increased workload, high diffusion temperature, etc., and achieve a favorable grain boundary phase Effect of continuous distribution, improvement of grain boundary phase distribution, and reduction of heavy rare earth content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

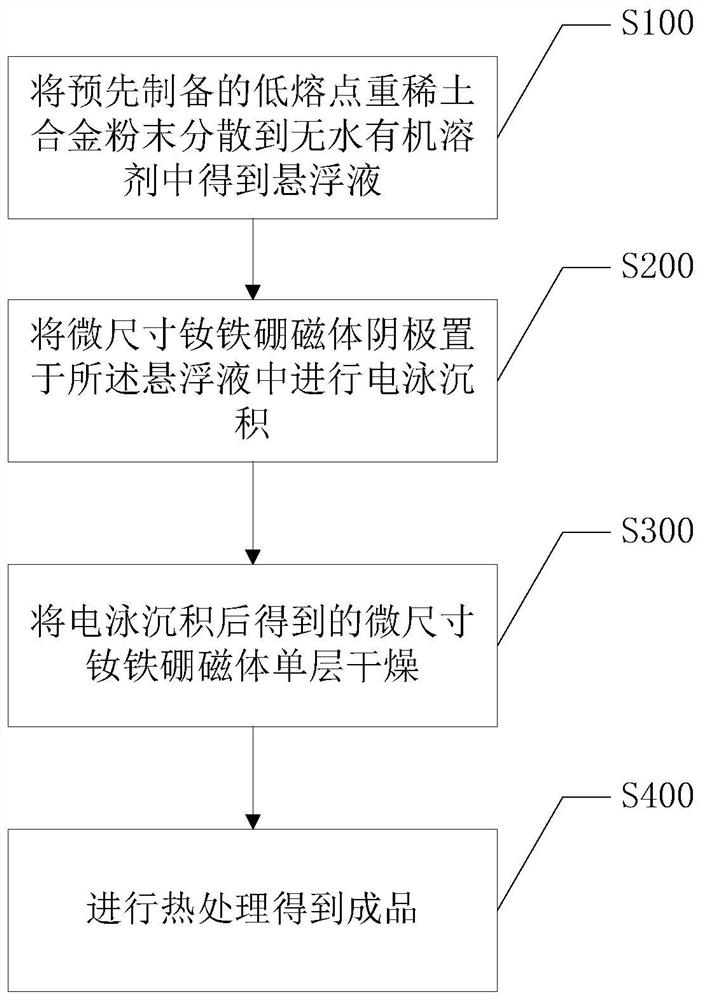

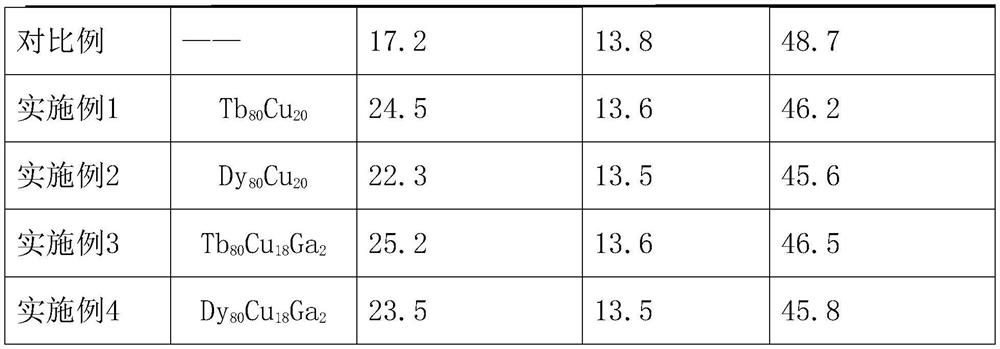

[0021] like figure 1 As shown, a method for preparing a micro-sized high-performance sintered NdFeB magnet includes preparing a low-melting point heavy rare earth alloy powder, preparing an electrophoretic solution, and an electrophoretic deposition process. The electrophoretic solution preparation process includes preparing the low melting point heavy rare earth alloy powder. Dispersed into anhydrous organic solvent to obtain a suspension, the electrophoretic deposition process includes placing a micro-sized NdFeB magnet as a cathode in the suspension for electrophoretic deposition, and then drying the electrophoretic deposited micro-sized NdFeB magnet and then performing heat treatment. The preparation of high-performance magnets in the existing electroacoustic field is mainly through the direct introduction of heavy rare earth elements through the alloy method or double alloy method, which can easily cause the even distribution of heavy rare earth elements Tb and Dy in the m...

Embodiment 2

[0034] The preparation method of the micro-sized sintered NdFeB magnet in this example is the same as the preparation method of the micro-sized sintered NdFeB magnet in Example 1, the difference is that the composition of the diffusion source is Dy 80 Cu 20 .

Embodiment 3

[0036] The preparation method of the micro-sized sintered NdFeB magnet in this example is the same as the preparation method of the micro-sized sintered NdFeB magnet in Example 1, the difference is that the composition of the diffusion source is Tb 80 Cu 18 Ga 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com