Solder strip for laminated photovoltaic module and laminated photovoltaic module

A photovoltaic module and ribbon technology, which is applied in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve the problems of increased battery shading area, increased ribbon resistance, and increased cost per watt to reduce the risk of process debris and ensure reliable components Improvement of properties and reduction of yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. These examples are only for illustrating the present invention and are not intended to limit the scope of the present invention.

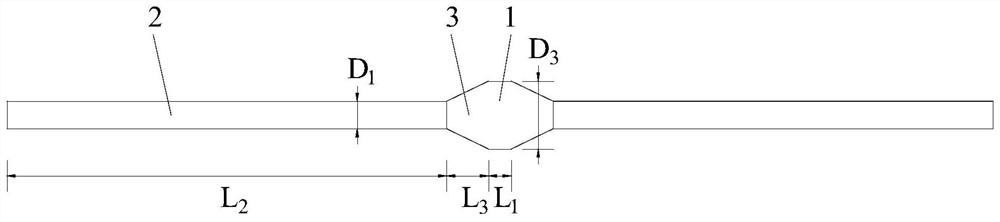

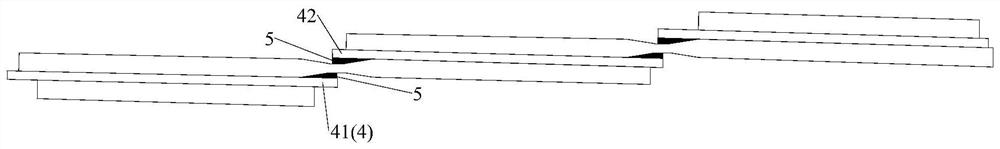

[0023] A kind of welding ribbon for laminated photovoltaic modules, as attached figure 1 , 2 As shown, the welding strip is divided into a middle section 1 , a head section 2 at both ends, and a transition section 3 between the middle section 1 and the head section 2 .

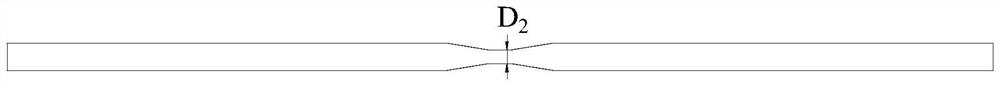

[0024] The cross section and longitudinal section of the middle section 1 are rectangular, the cross section of the head section 2 is rectangular, the longitudinal section is circular, the cross section of the transition section 3 is trapezoidal, the longitudinal section is rectangular, and the diameter of the head section 2 is D 1 >Thickness D of middle section 1 2 , the thickness of the transition section 3 from D 1 to D 2 Gradient, and symmetr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com