Vanadium pentoxide and rGO co-coated gradient ternary positive electrode material and preparation method thereof

A technology of vanadium pentoxide and positive electrode materials, which is applied in the direction of vanadium oxide, chemical instruments and methods, positive electrodes, etc., can solve the problem that the complete conversion of vanadium pentoxide cannot be guaranteed, the precursor of ternary materials is not suitable for wide use, and hinders diffusion And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

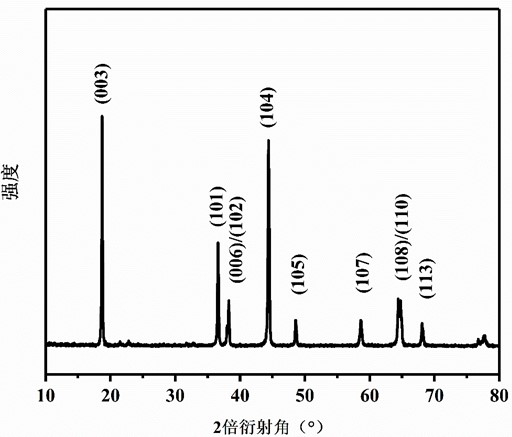

[0072] Example 1 Gradient LiNi co-coated with vanadium pentoxide and rGO 0.84 co 0.11 mn 0.05 o 2 Cathode material

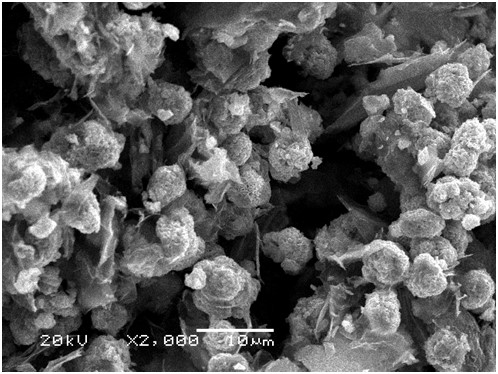

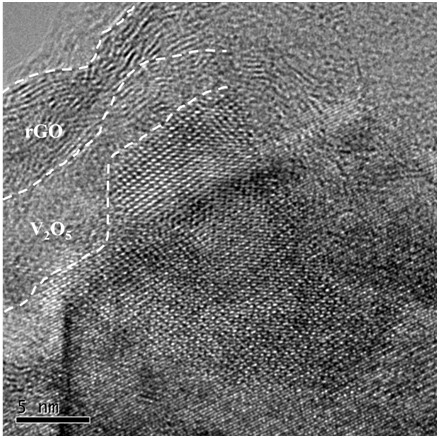

[0073] The positive electrode material is composed of two layers of vanadium pentoxide and rGO coated LiNi 0.84 co 0.11 mn 0.05 o 2 Formed spherical core-shell particles; the LiNi 0.84 co 0.11 mn 0.05 o 2 The mass ratio with vanadium pentoxide and rGO is 1:0.03:0.03; the LiNi 0.84 co 0.11 mn 0.05 o 2 For the full gradient material, the content of nickel element is from LiNi 0.84 co 0.11 mn 0.05 o 2 From the center to the surface gradually decreases, the content of manganese element from LiNi 0.84 co 0.11 mn 0.05 o 2 From the center to the surface, the content of cobalt element is higher than that of LiNi 0.84 co 0.11 mn 0.05 o 2 uniform distribution; the vanadium pentoxide and rGO co-coat gradient LiNi 0.84 co 0.11 mn 0.05 o 2 The average particle size of the vanadium pentoxide coating layer is 6 μm; the average thickness of the vana...

Embodiment 2

[0088] Example 2 Gradient LiNi co-coated with vanadium pentoxide and rGO 0.84 co 0.11 mn 0.05 o 2 Cathode material

[0089] The positive electrode material is composed of two layers of vanadium pentoxide and rGO coated LiNi 0.84 co 0.11 mn 0.05 o 2 Formed spherical core-shell particles; the LiNi 0.84 co 0.11 mn 0.05 o 2 The mass ratio with vanadium pentoxide and rGO is 1:0.03:0.02; the LiNi 0.84 co 0.11 mn 0.05 o 2 For the full gradient material, the content of nickel element is from LiNi 0.84 co 0.11 mn 0.05 o 2 From the center to the surface gradually decreases, the content of manganese element from LiNi 0.84 co 0.11 mn 0.05 o 2 From the center to the surface, the content of cobalt element is higher than that of LiNi 0.84 co 0.11 mn 0.05 o 2 uniform distribution; the vanadium pentoxide and rGO co-coat gradient LiNi 0.84 co 0.11 mn 0.05 o 2 The average particle size of the positive electrode material is 5 μm; the average thickness of the vanadium ...

Embodiment 3

[0104] Example 3 Gradient LiNi co-coated with vanadium pentoxide and rGO 0.82 co 0.12 mn 0.06 o 2 Cathode material

[0105] The positive electrode material is composed of two layers of vanadium pentoxide and rGO coated LiNi 0.82 co 0.12 mn 0.06 o 2 Formed spherical core-shell particles; the LiNi 0.82 co 0.12 mn 0.06 o 2 The mass ratio with vanadium pentoxide and rGO is 1:0.04:0.03; the LiNi 0.82 co 0.12 mn 0.06 o 2 For the full gradient material, the content of nickel element is from LiNi 0.82 co 0.12 mn 0.06 o 2 From the center to the surface gradually decreases, the content of manganese element from LiNi 0.82 co 0.12 mn 0.06 o 2 From the center to the surface, the content of cobalt element is higher than that of LiNi 0.82 co 0.12 mn 0.06 o 2 uniform distribution; the vanadium pentoxide and rGO co-coat gradient LiNi 0.82 co 0.12 mn 0.06 o 2 The average particle size of the positive electrode material is 7 μm; the average thickness of the vanadium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com