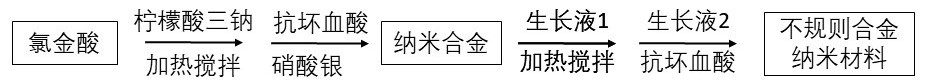

Preparation method of alloy semiconductor composite nano material based on aqueous phase synthesis and alloy semiconductor composite nano material

A composite nanomaterial and semiconductor technology, applied in the field of alloy nanomaterial synthesis, can solve the problems of poor performance improvement ability of alloy semiconductor composite nanomaterials, and achieve the effects of improving photothermal conversion performance, easy control, and green and simple synthesis mechanism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

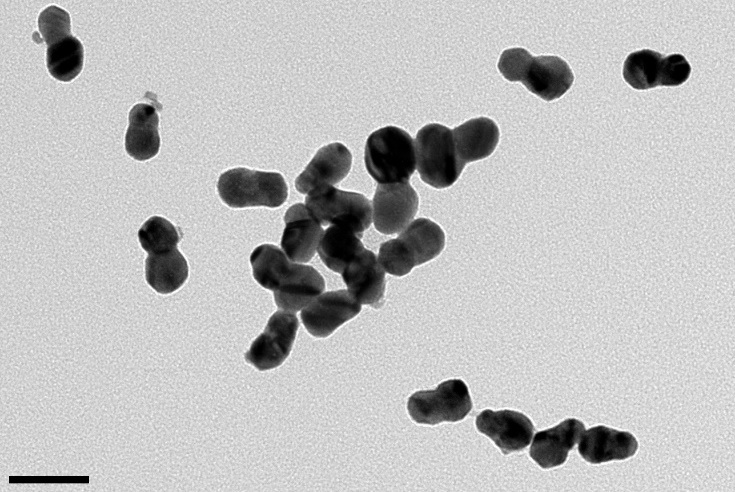

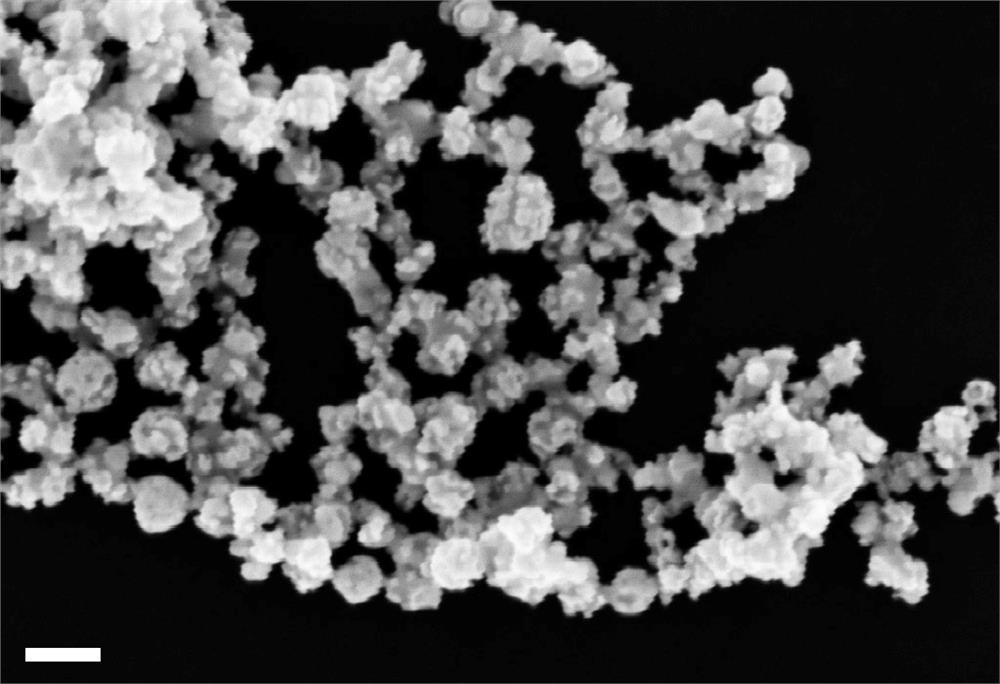

[0041] The existing preparation methods of photothermal composite nanomaterials are relatively complicated, and the photothermal performance of the composite material is limited, due to the unsatisfactory coupling effect of the localized surface plasmon of the material, the large gap between the materials, and the excessive thickness of the composite shell , which is not conducive to the application of the material. Based on the synthesis of the original nanomaterials, the method provided by the present invention uses the irregular alloy material as the base to design and prepare an alloy semiconductor composite nanomaterial by using the chemical replacement method. By effectively coupling the LSPR of the two materials, the The light-to-heat conversion efficiency of nanomaterials.

[0042] The method for preparing alloy semiconductor composite nanomaterials based on aqueous phase synthesis provided by the present invention is simply divided into four parts: solution preparatio...

Embodiment 1

[0061] 1. Solution preparation

[0062] Weigh 1 g of chloroauric acid trihydrate (HAuCl 4 ·3H 2 O, Au 23.5-23.8%) powder was added to 80 mL of deionized water three times, and ultrasonically dissolved to obtain a 1% wt chloroauric acid solution; 100 mg of trisodium citrate (C 6 h 5 Na 3 o 7 , 99%) powder was added to 10 mL of deionized water for three times, and ultrasonically dissolved to obtain a 1% wt trisodium citrate solution; weigh 0.02 g of silver nitrate (AgNO 3 , 98%) powder was added into 10 mL of deionized water three times, and dissolved by ultrasonic to obtain a 2% wt silver nitrate solution.

[0063] Seed Growth Solution 1 made of Tween 20 (C 58 h 114 o 26 ), copper acetate (Cu(Ac) 2 ·H 2 O, 98%), sodium hydroxide (NaOH, 99%) and trisodium citrate, weighed 0.2 mL Tween 20, 0.39 g copper acetate, 0.16 g sodium hydroxide and 0.33 g trisodium citrate powder, Add it into 40 mL of deionized water three times, and dissolve it ultrasonically to obtain a 2% wt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com