Preparation method of foamed nickel-based photothermal conversion material

A light-to-heat conversion material and nickel foam technology, which is applied in the coating process of metal materials, etc., can solve the problems of high cost, large heat loss, and complicated preparation process, and achieve the effect of good bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

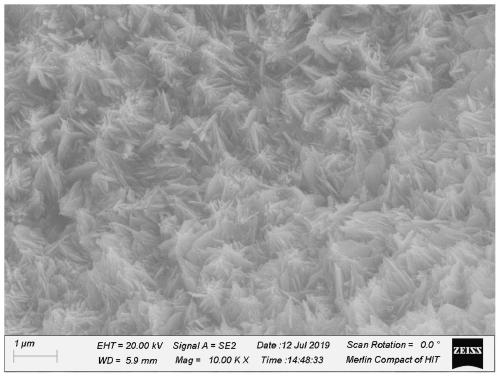

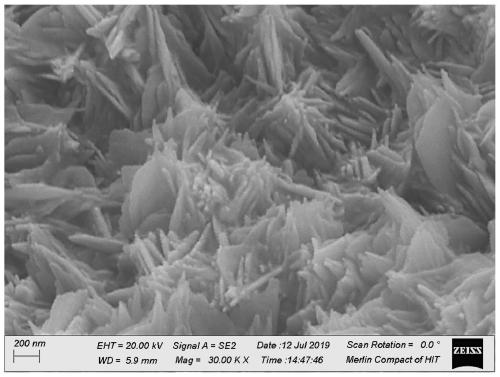

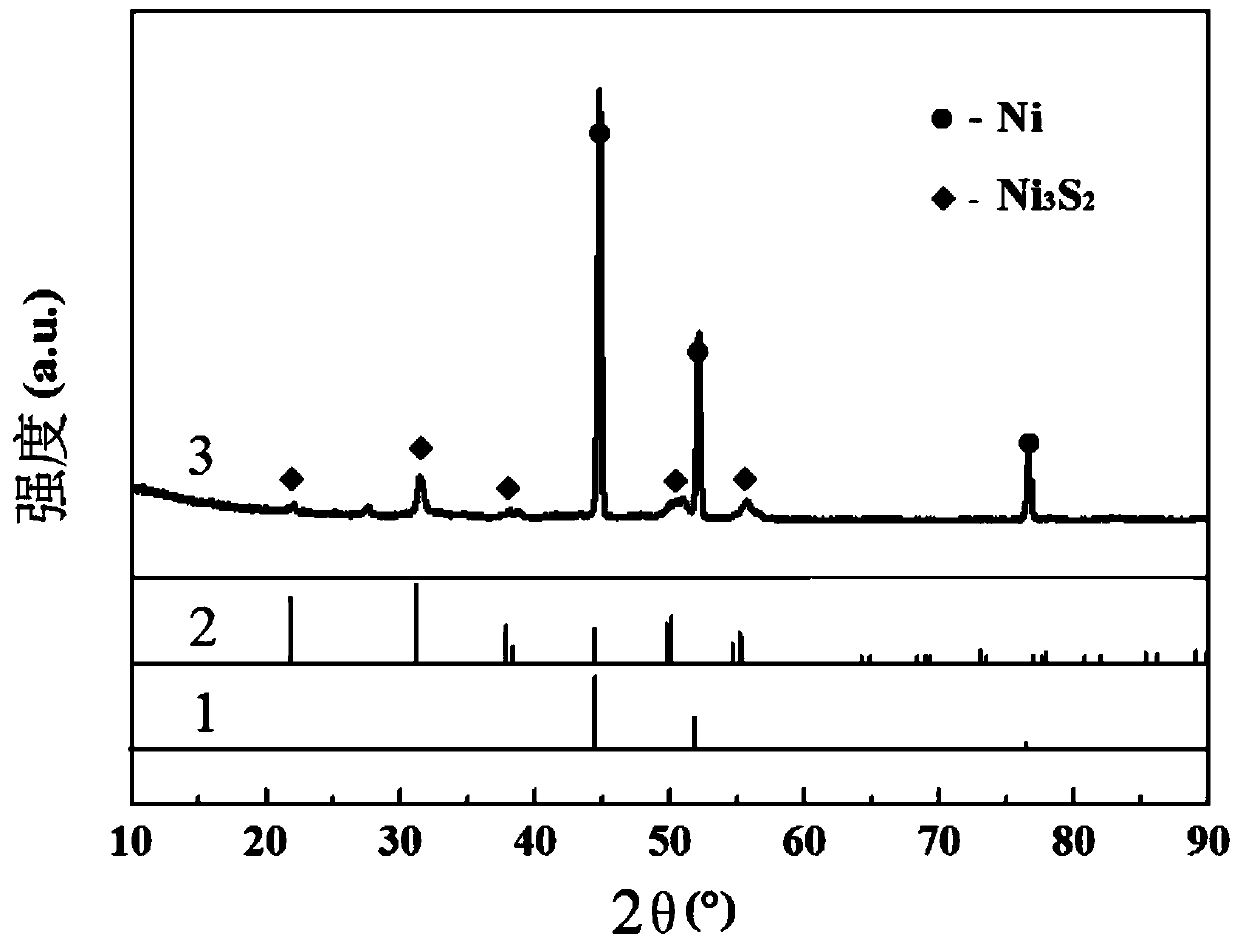

[0023] Specific implementation mode 1: This implementation mode is a preparation method of foamed nickel-based light-to-heat conversion material, which is completed according to the following steps:

[0024] 1. Nickel foam pretreatment

[0025] ①. First, immerse the nickel foam in hydrochloric acid for ultrasonication, then immerse it in deionized water for ultrasonication, and finally immerse it in absolute ethanol for ultrasonication;

[0026] ②. First, use absolute ethanol to clean the foamed nickel for 3 to 5 times, then use deionized water to clean the foamed nickel for 3 to 5 times, and finally use a hair dryer to dry the foamed nickel to obtain the pretreated foamed nickel;

[0027] 2. Solvothermal reaction:

[0028] 1. Disperse thiourea in absolute ethanol to obtain a supersaturated solution of thiourea in absolute ethanol;

[0029] ②. Transfer the supersaturated solution of thiourea in absolute ethanol to a high-pressure reactor lined with polytetrafluoroethylene, t...

specific Embodiment approach 2

[0034] Embodiment 2: The differences between this embodiment and Embodiment 1 are: the pore density of the nickel foam described in step ① is 110 ppi, and the thickness is 1.5 mm to 2 mm. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0035] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the nickel foam described in step ① is a cylinder with a diameter of 3.6 cm. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com