Riser raw gas disturbance method and device based on coke dry quenching circulating gas

A technology of circulating gas and disturbance method, which is applied to the discharge device of dry distillation gas, heating of coke oven, coke oven, etc. Stable and reliable, strengthen the effect of convection heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

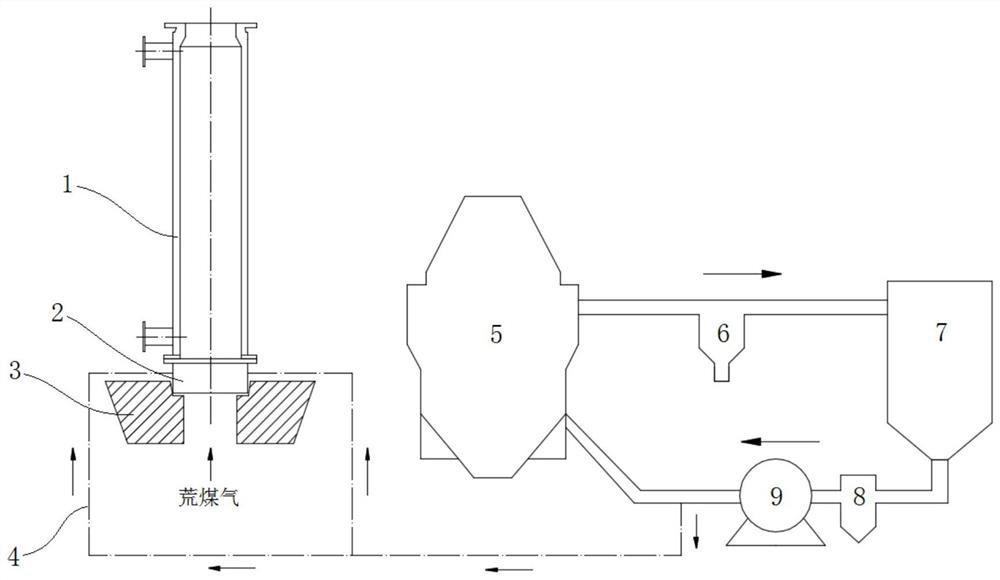

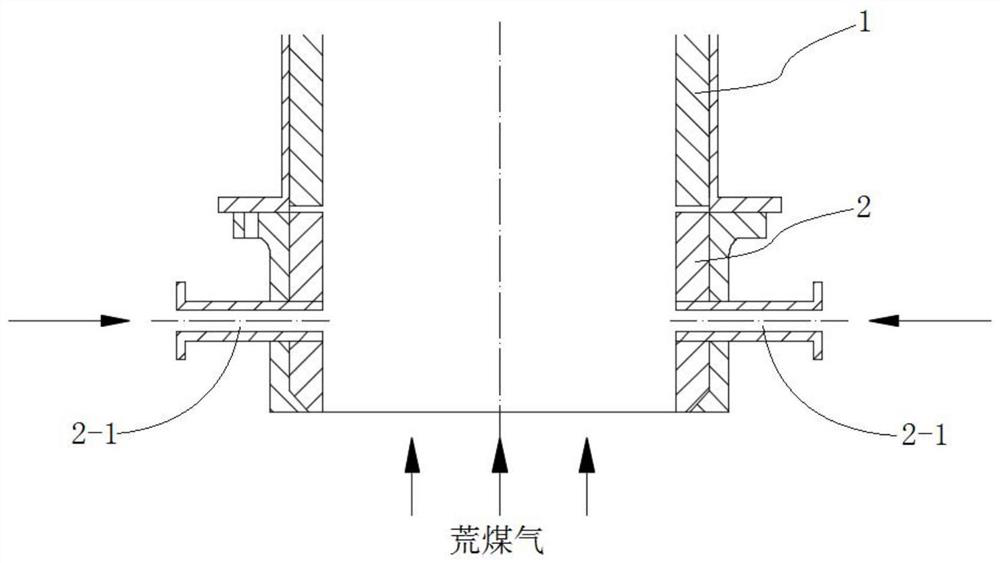

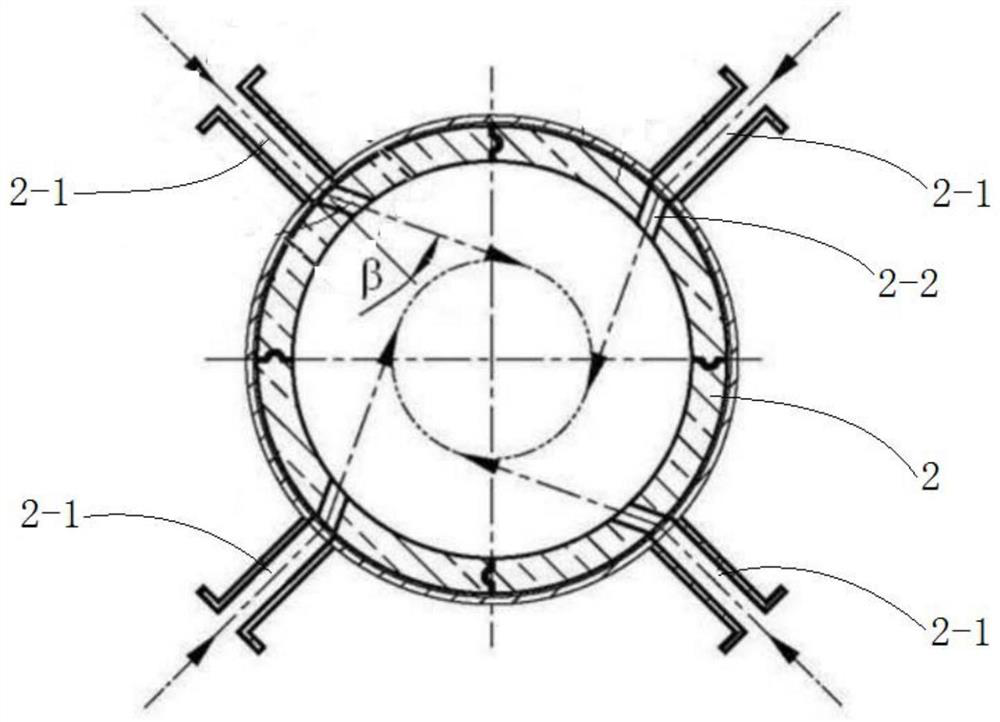

[0036] Such as figure 1 , figure 2 and image 3 As shown, in this embodiment, a method for disturbing raw gas in the riser pipe based on CDQ circulating gas, a rotating air inlet 2-2 inclined to one side is provided on the riser base 2 of the riser heat exchanger 1, The orientation deflection angle of the rotating air inlet hole 2-2 is β, and the rotating airflow can be generated through the air intake through the rotating air inlet hole 2-2. 4 Connect to the rotating air inlet hole 2-2 of the riser base 2, under the action of the circulation fan 9, part of the circulating gas in the CDQ circulation system enters the riser base 2, and the CDQ circulation gas is used in the riser A rotating disturbed airflow is formed in the base 2, and the rotating disturbed airflow drives the rising raw gas, so that the raw gas in the rising pipe heat exchanger 1 forms a rotating upward movement, and the rotating rising raw gas can realize the central raw gas and the rising pipe heat excha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com